A high stem crop binding device

A technology for bundling devices and crops, applied in harvesters, agriculture, applications, etc., can solve the problems of high labor intensity, low production efficiency, and low bundling operation efficiency, and achieve low operating costs, high production efficiency, and automatic packaging. The effect of tying work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

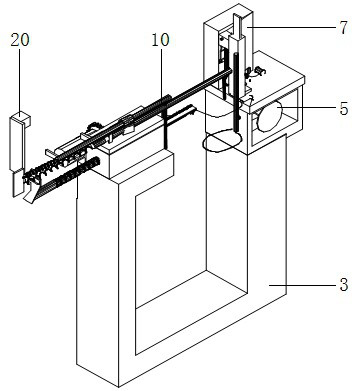

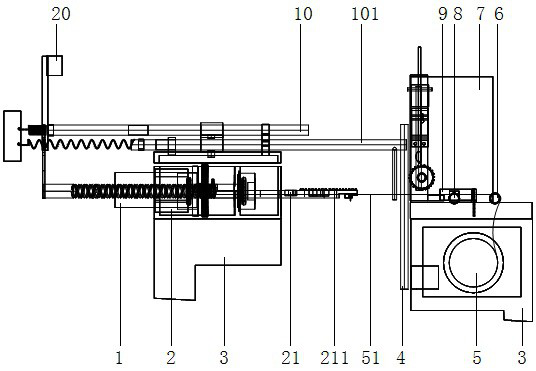

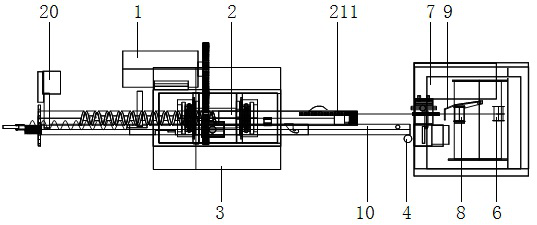

[0029] refer to Figure 1 to Figure 6 , the present invention is achieved in this way: a high-stalk crop binding device, which includes a frame 3, a driving device 1, a deceleration shuttle box assembly 2, a rope seat 5, a needle clamp 7, a rope puller 8, a breaker The rope cutter 9 and the spring identification assembly 10, the frame 3 has a U-shaped cross-section, the driving device 1, the deceleration shuttle box assembly 2 and the spring identification assembly 10 are installed on the top of one end of the U-shaped opening of the frame 3, and the The needle card 7, the rope puller 8 and the rope cutter 9 are installed on the top of the other end of the U-shaped opening of the frame 3; when the crop 30 is transported into the U-shaped opening of the frame 3, the spring identification assembly 10 measures the crop 30 to a certain level. When the weight is heavy, control the operation of the driving device 1 and drive the shuttle bar 21 to move horizontally to the other end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com