Wet type boiler flue gas desulfurization and dust removal device

A boiler flue gas, desulfurization and dust removal technology, which is applied in the direction of combination device, separation device, gas treatment, etc., can solve the problems of endangering the living environment of animals and plants, endangering people's health, and secondary pollution of the environment, so as to achieve enhanced ride comfort and enhanced Desulfurization and dust removal effect, effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

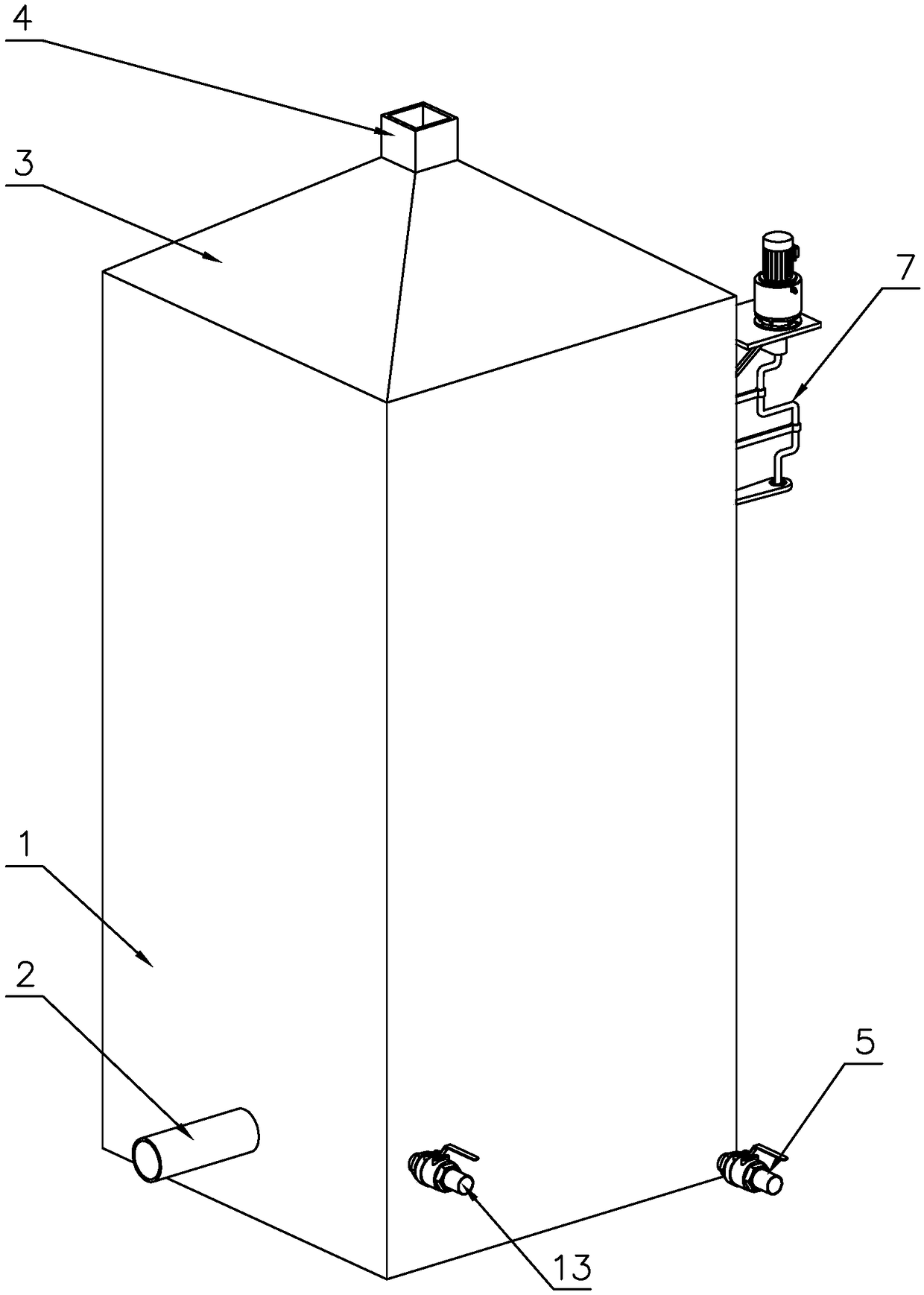

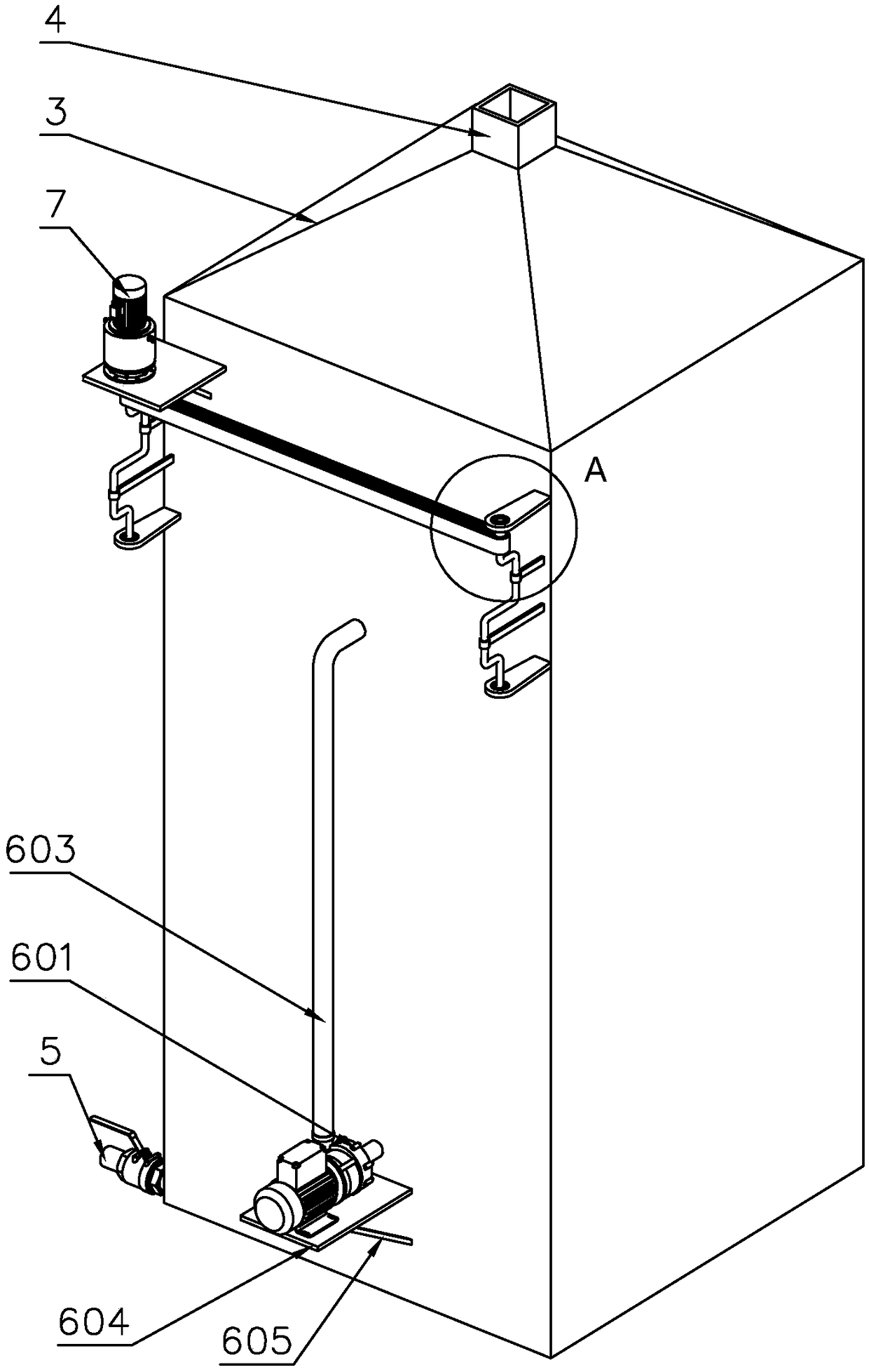

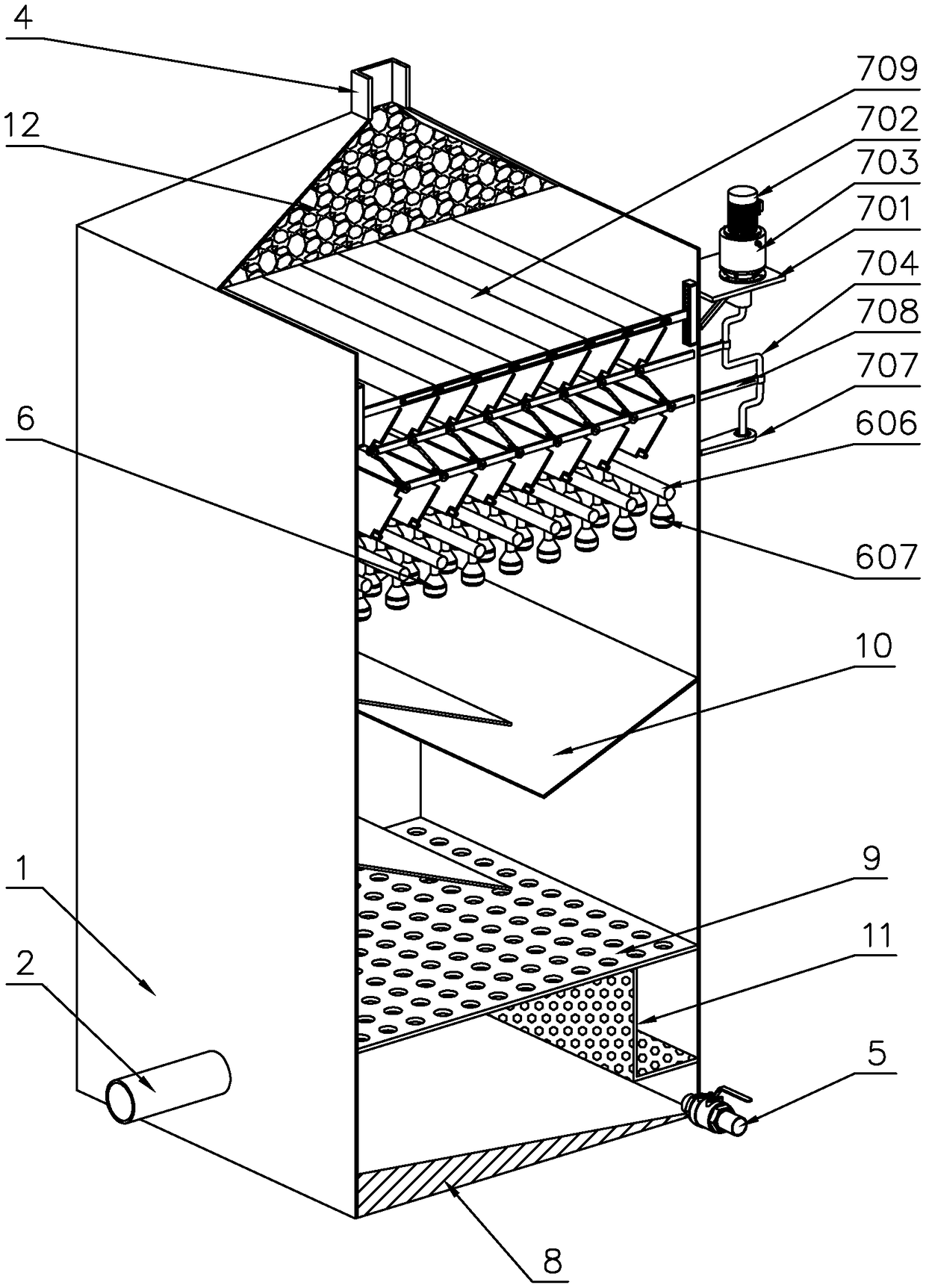

[0045] A wet boiler flue gas desulfurization and dust removal device, comprising a body 1, an air inlet pipe 2, a gas collecting hood 3, an air outlet pipe 4, a sewage pipe 5, a spray device 6, a demisting device 7, and a liquid feeding pipe 13. The body 1 One side of the lower part is provided with a bottom plate 8, and one side of the upper part of the bottom plate 8 is provided with an air inlet pipe 2, one end of the air inlet pipe 2 extends into the interior of the body 1, and the other end is connected with the gas pipeline; the lower side of the interior of the body 1 is provided with a washing liquid , and the gas outlet of the intake pipe 2 is located inside the water washing liquid, the boiler flue gas enters the interior of the body 1 through the air intake pipe 2, and desulfurization and dust removal are carried out through the water washing liquid to remove most of the dust in the flue gas and neutralize part of the sulfur dioxide;

[0046] The inner side of the bo...

Embodiment 2

[0057] The difference from Example 1 is that: the inner side of the gas collecting hood 3 is provided with a packing layer 12, and the packing layer 12 is an activated carbon packing layer. The discharge of washing liquid; on the other hand, it can absorb the peculiar smell in the flue gas and protect the environment.

Embodiment 3

[0059] The difference from Example 1 is that an air distribution plate 9 is provided on the inner side of the body 1, and a number of air distribution holes are provided on the air distribution plate 9. The uniformity of flue gas distribution inside the body 1 is improved, thereby enhancing the desulfurization and dust removal effect of flue gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com