Saturated active carbon regeneration equipment

A regeneration equipment and activated carbon technology, which is applied in filter regeneration, filtration separation, petroleum industry, etc., can solve the problems of complex equipment, poor regeneration effect of activated carbon particles, slow processing speed, etc., achieve good effect, good activation effect, fast activation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

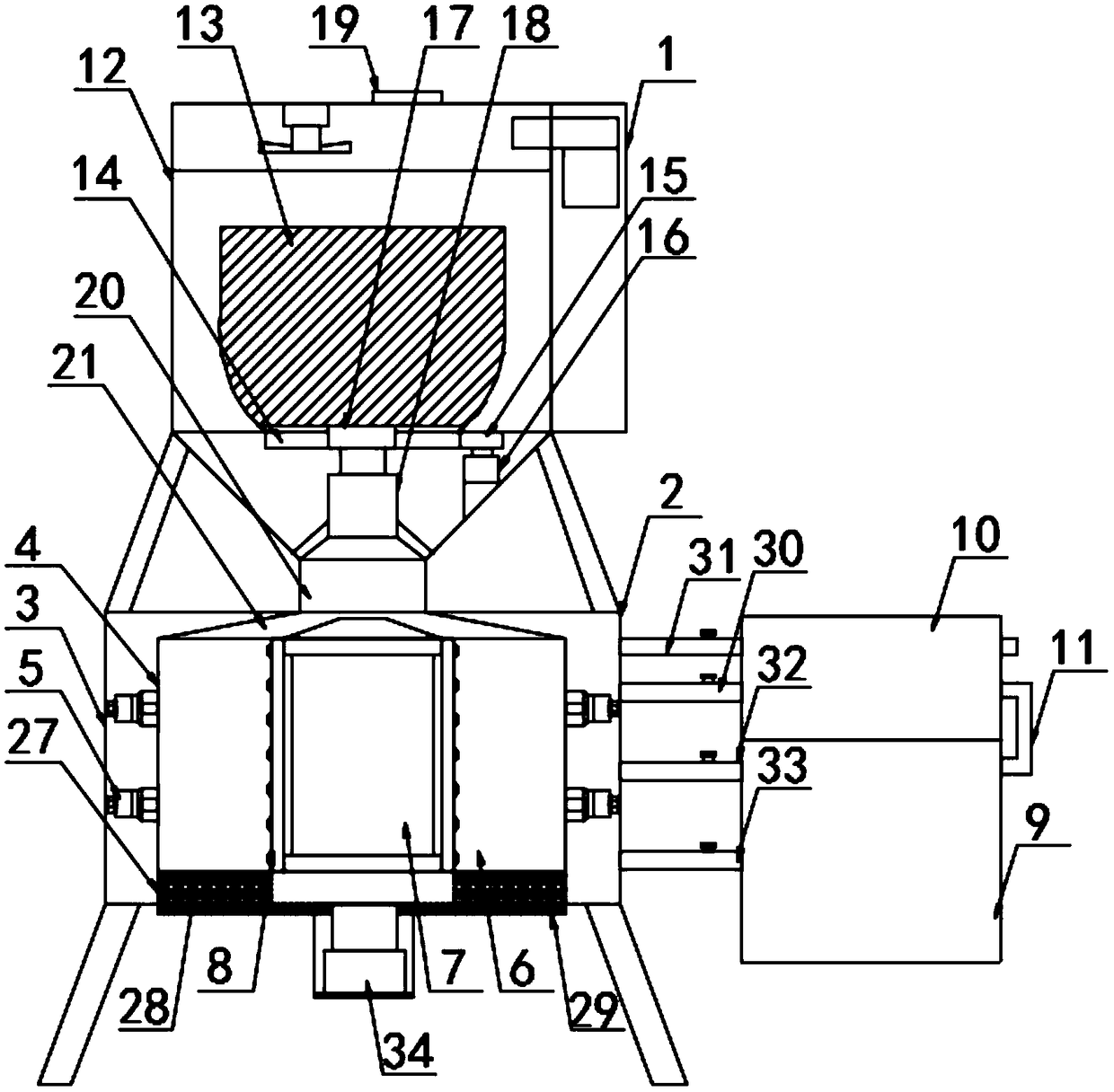

[0023] according to figure 1 A saturated activated carbon regeneration device shown includes a microwave primary heating mechanism 1 and an ultrasonic secondary heating mechanism 2, the ultrasonic secondary heating mechanism 2 is arranged at the bottom of the microwave primary heating mechanism 1, and the ultrasonic secondary heating mechanism 2 includes The body 3 is fixed with an annular vibrating steel plate 4 inside the body 3, a transducer 5 is arranged between the annular vibrating steel plate 4 and the body 3, and a regeneration cavity 6 is arranged inside the annular vibrating steel plate 4, and the regenerative Inside the cavity 6 is provided with an inner heating cylinder 7 and a pipeline assembly 8, a heating water tank 9 is provided on one side of the ultrasonic secondary heating mechanism 2, a steam heater 10 is provided on the top of the heating water tank 9, and a steam heater 10 is provided on the top of the heating water tank 9 A U-shaped pipe 11 is provided o...

Embodiment 2

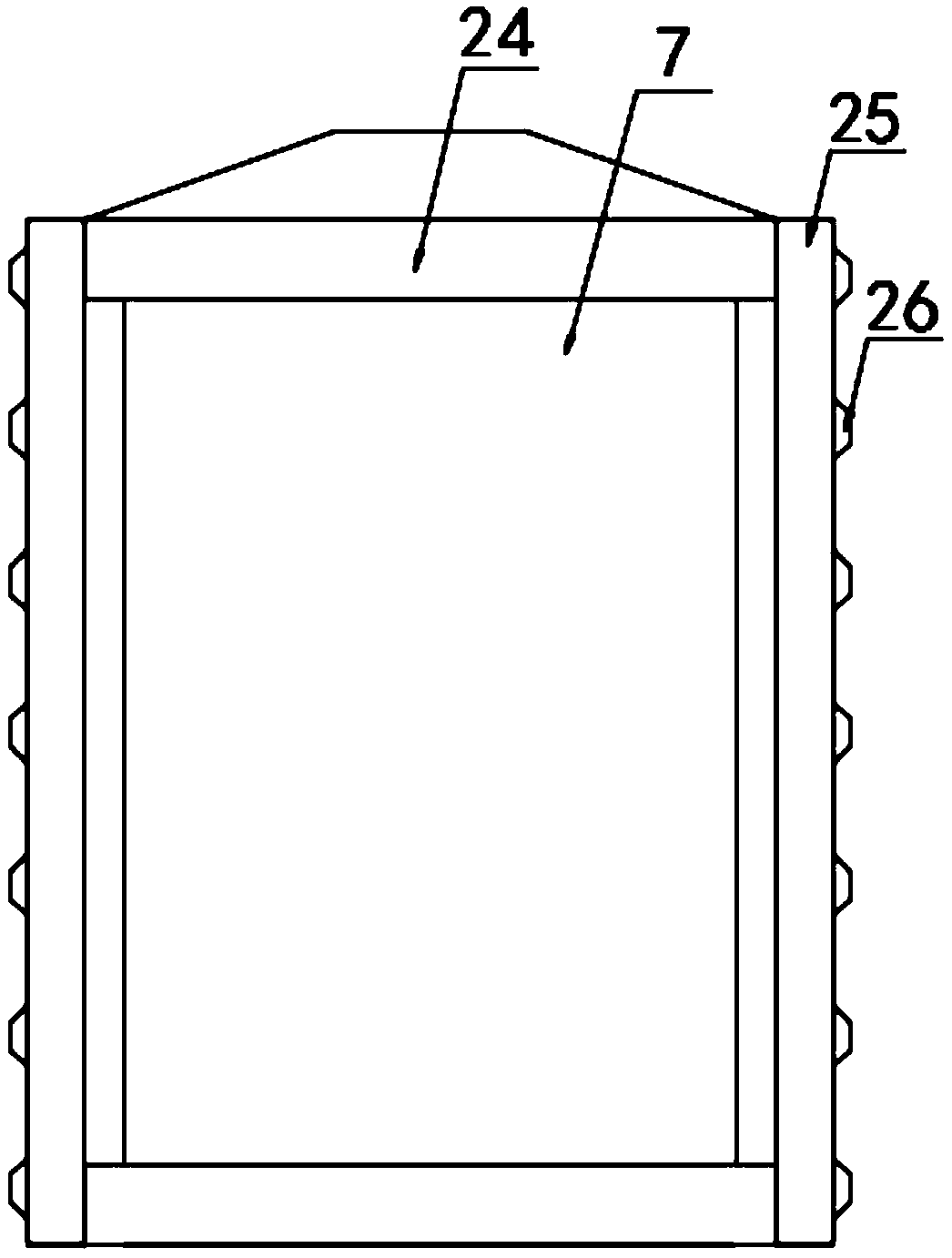

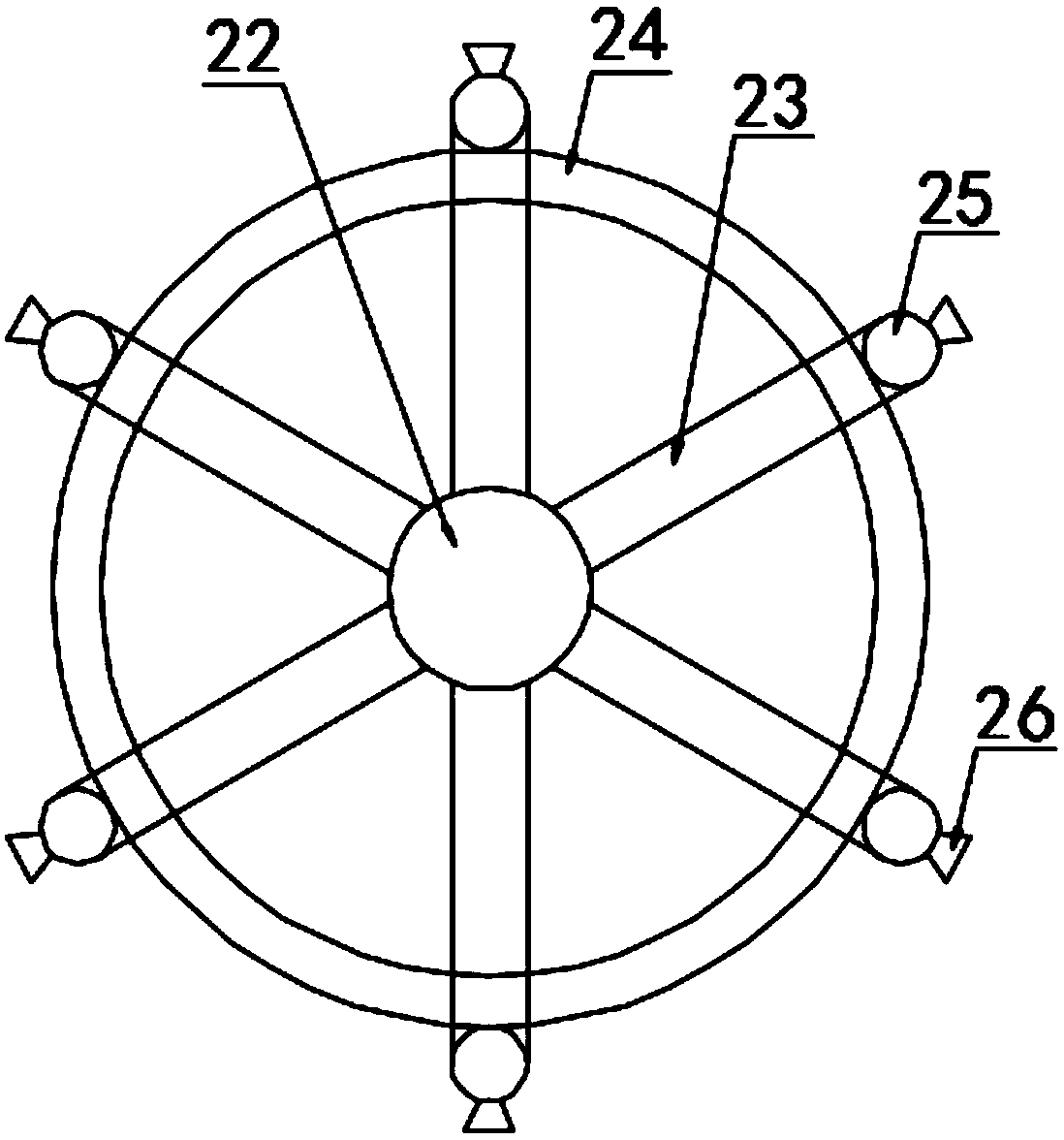

[0029] according to Figure 2-3In the shown saturated activated carbon regeneration equipment, the pipeline assembly 8 is arranged on the outside of the inner heating cylinder 7, the pipeline assembly 8 includes an inner main pipe 22, and the inner main pipe 22 is externally connected with a plurality of branch pipes 23, so The outer side of the branch pipe 23 is fixed with an annular support 24, and the annular support 24 is fixedly connected with the inner heating cylinder 7. The bottom of the branch pipe 23 is connected with a vertical pipe 25, and the outer side of the vertical pipe 25 is fixed with a nozzle 26, which can evenly Pass hot water or hot air into the regeneration chamber 6, so that the internal activated carbon particles can be regenerated consistently and quickly;

[0030] according to Figure 4 As shown in the saturated activated carbon regeneration equipment, the bottom of the body 3 corresponding to the outer side of the inner heating cylinder 7 is provid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap