Casting mold base plate casting hole punching device

A technology for casting molds and punching devices, which is used in manufacturing tools, casting equipment, boring/drilling, etc., can solve problems such as unsatisfactory effect, low manual operation efficiency, and blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

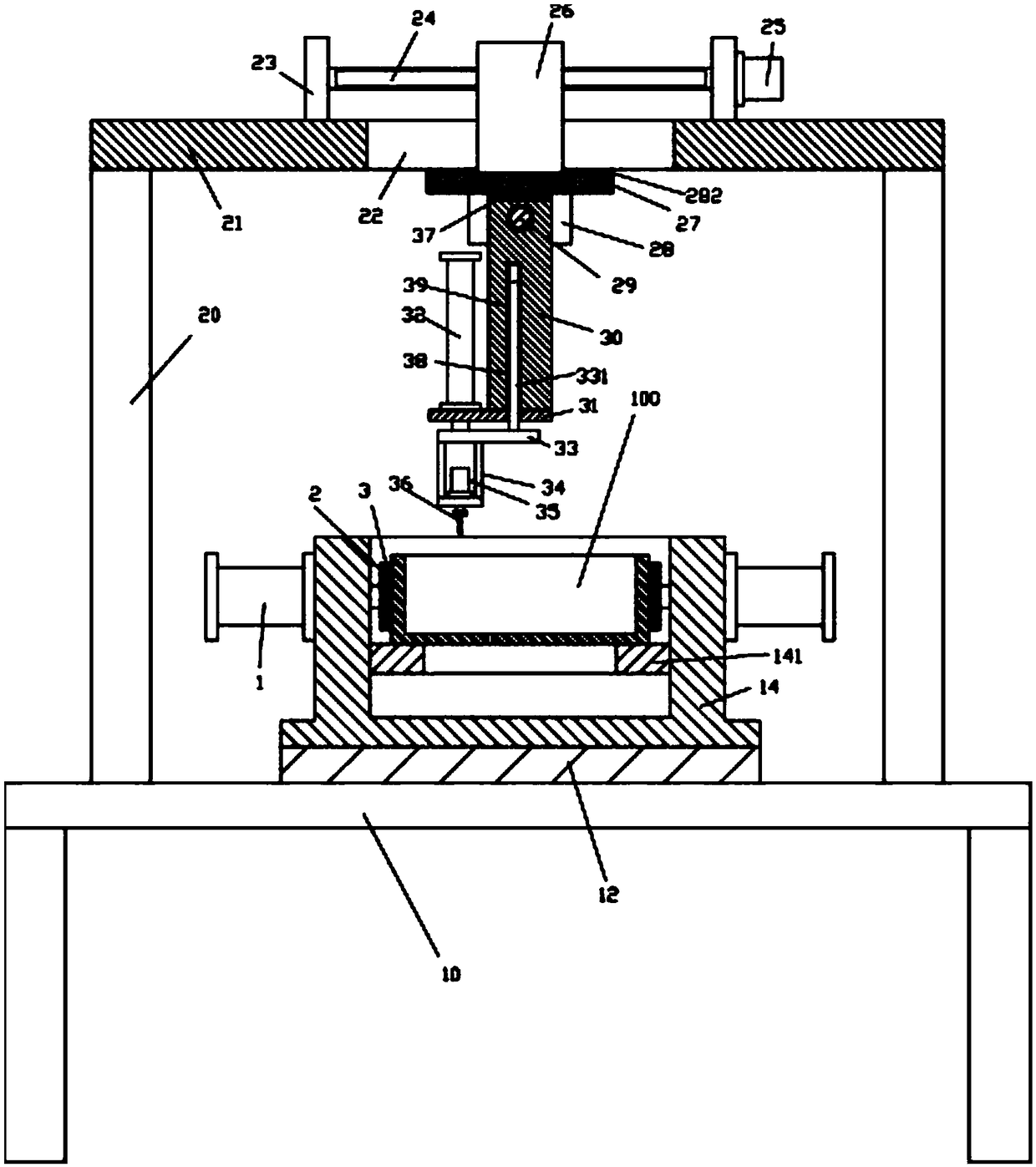

[0017] Examples, see e.g. Figure 1 to Figure 2 As shown, a casting mold bottom plate casting hole punching device includes a frame 10, the middle part of the top plate of the frame 10 is fixed with a mold mounting plate 12, and the top surface of the mold mounting plate 12 is fixed with a placement installation groove 14, A limit support edge 141 is fixed on the inner side wall of the placement and installation tank 14, the casting mold 100 to be processed is inserted into the placement installation tank 14, and the bottom surface of the casting mold 100 to be processed is pressed against the top surface of the limit support edge 141 ;

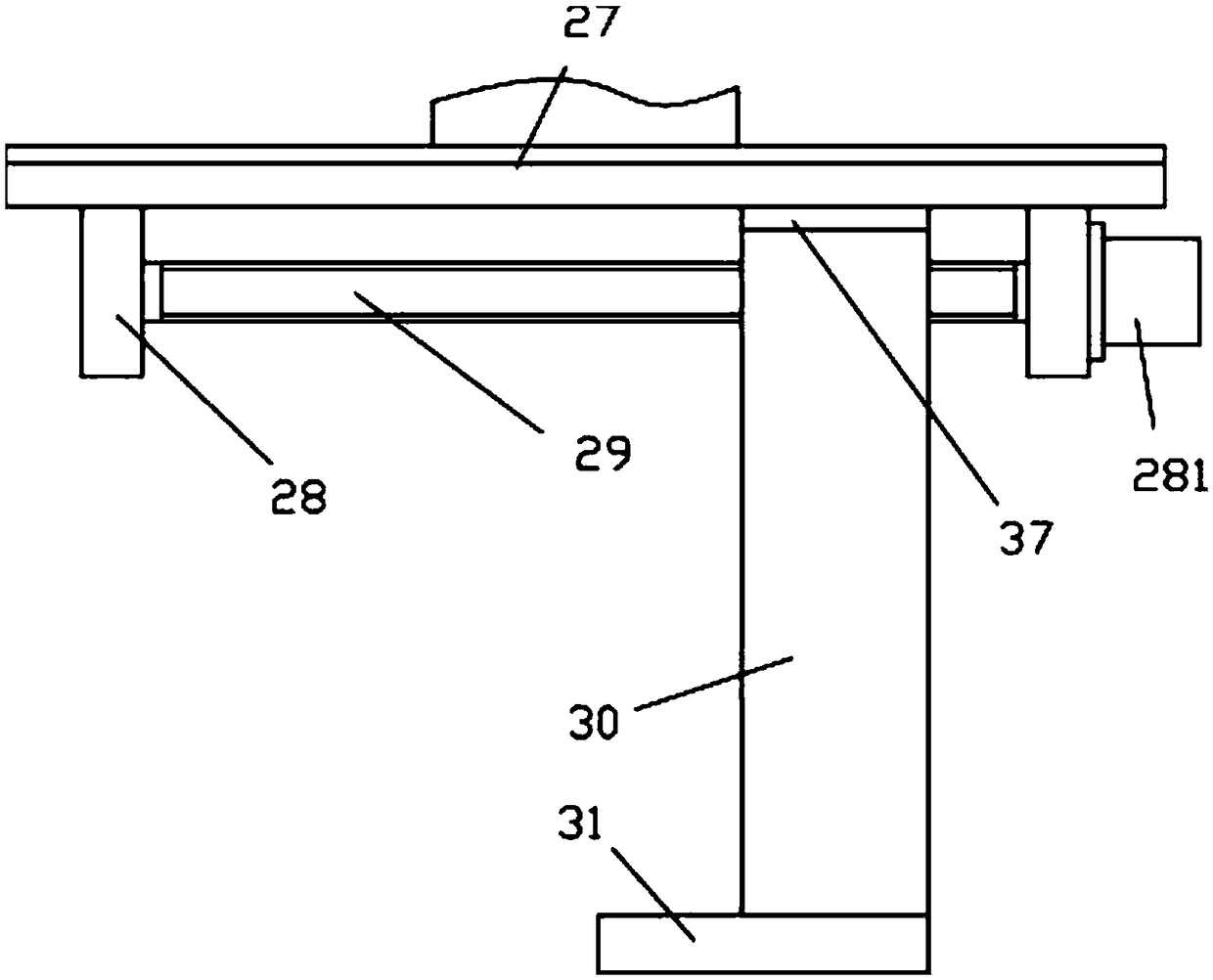

[0018] The left and right parts of the top surface of the top plate of the frame 10 are all fixed with an upper vertical plate 20, and the upper horizontal main board 21 is fixed on the top surface of two upper vertical plates 20, and the middle part of the upper horizontal main board 21 has a lateral movement Through groove 22, the top surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com