Ultrasonic welding head

An ultrasonic and welding head technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of slipping, burning, and virtual welding of welding workpieces, and achieve the effect of solving slipping and improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

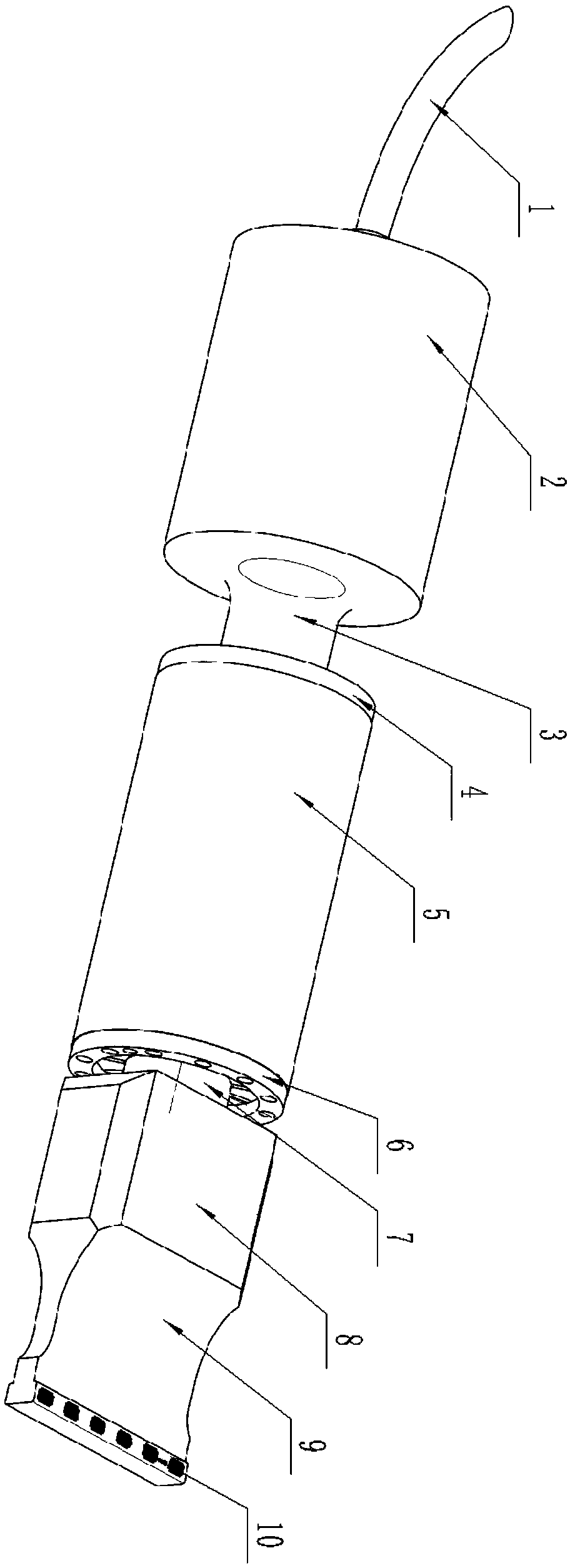

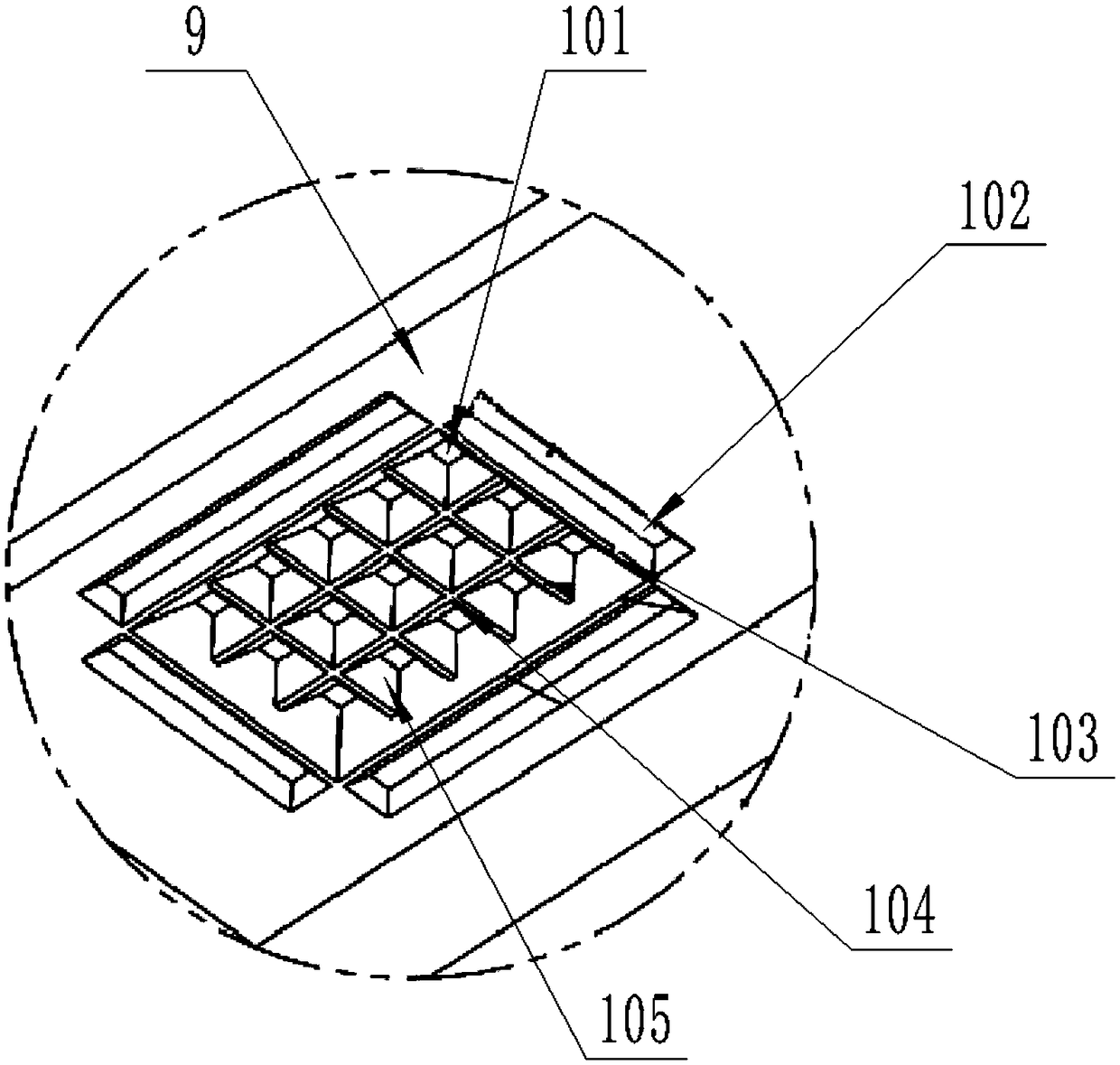

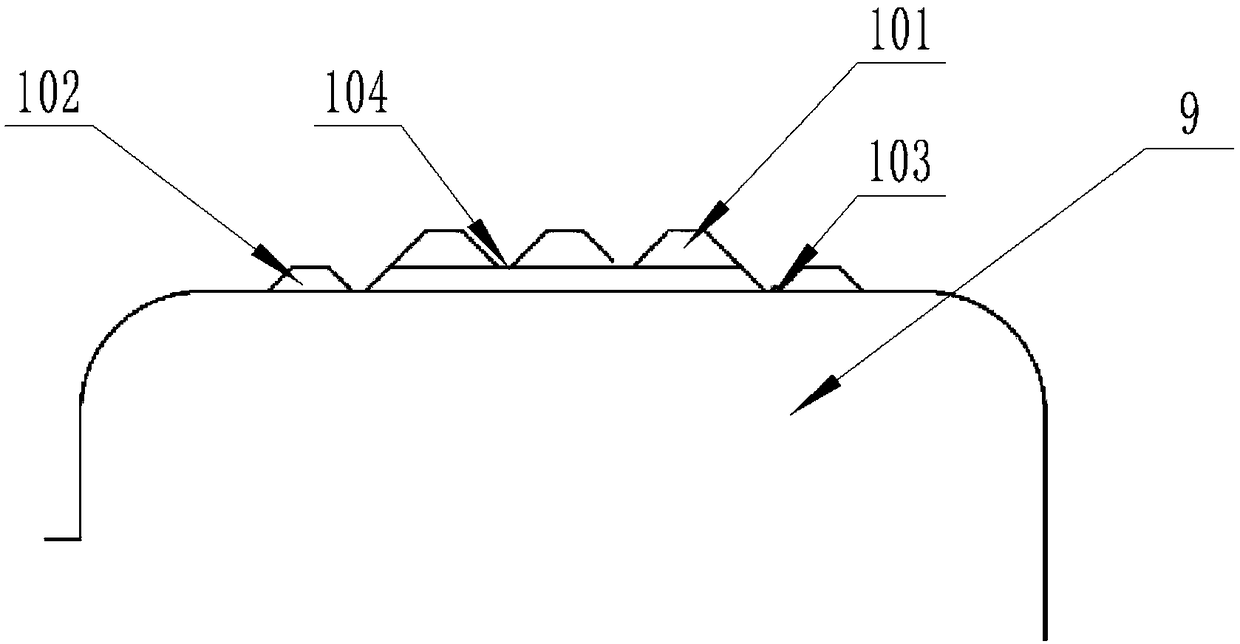

[0014] Such as figure 1 As shown, this specific embodiment adopts the following technical solutions: an ultrasonic welding head, including a signal line 1, a transducer shell 2, a front part of the transducer 3, a rear connecting flange 4, a connecting sleeve 5, a front Connecting flange 6, welding head connection round platform 7, welding head power storage part 8, welding head emitting part 9 and welding head working part 10; the signal line 1 is used to transmit high-frequency and high-voltage electrical signals; the energy conversion The housing 2 of the transducer can be used for clamping and insulation protection to prevent electric shock; the front part of the transducer 3 adopts an inverted funnel shape, which is conducive to the concentration of ultrasonic energy, reduces the influence of transverse waveforms, and improves the efficiency of ultrasonic transmission. Efficiency; the rear connecting flange 4 is mainly used to press the bottom of the transducer, and a cer...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap