Overspeed automatic brake system of mining endless rope winch

A technology of infinite rope winch and automatic braking, which is applied in the direction of hoisting device, etc., can solve the problems of brake failure, malfunction, and failure to brake, etc., and achieve the effect of simple use, strong reliability and high braking safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

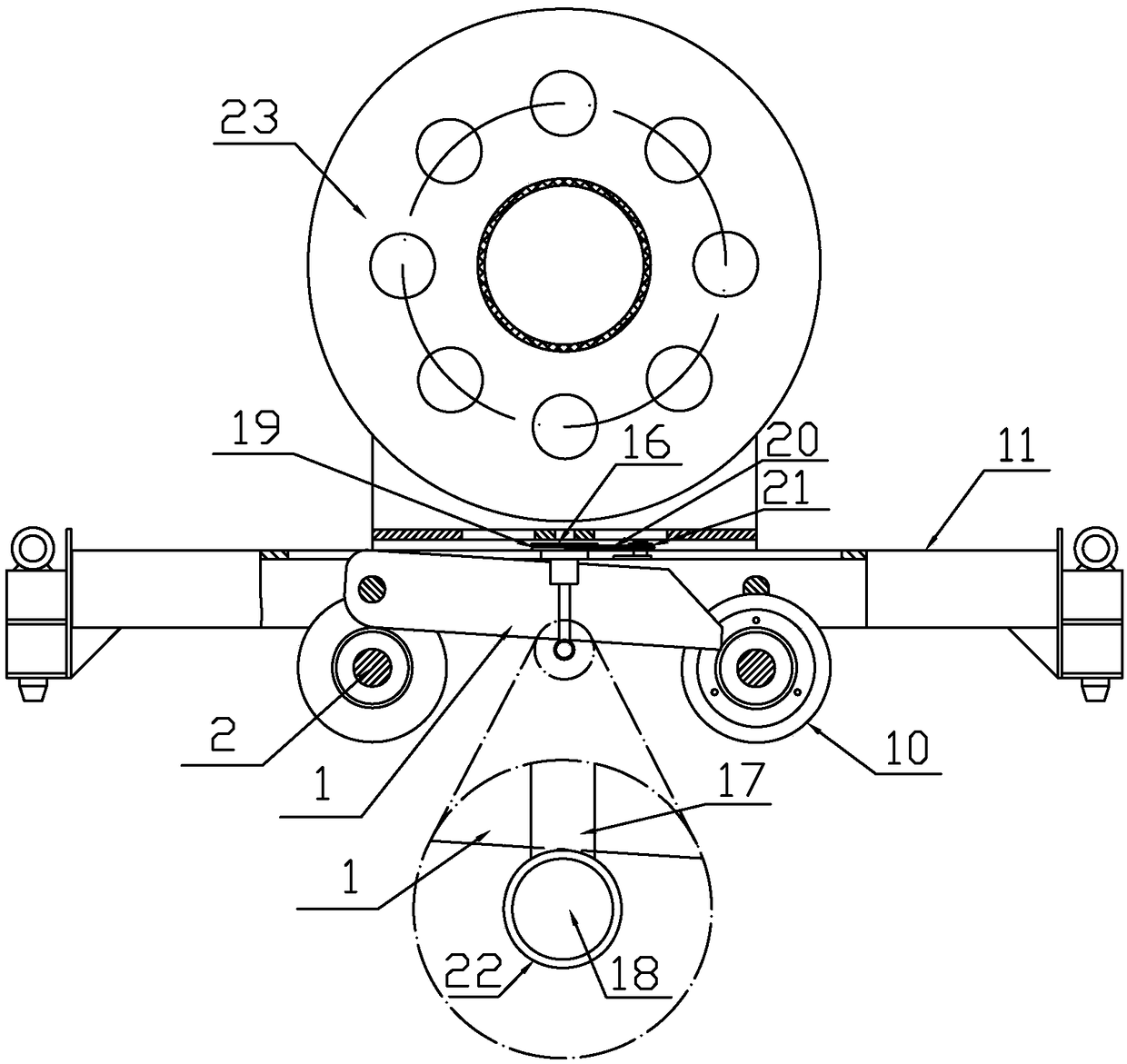

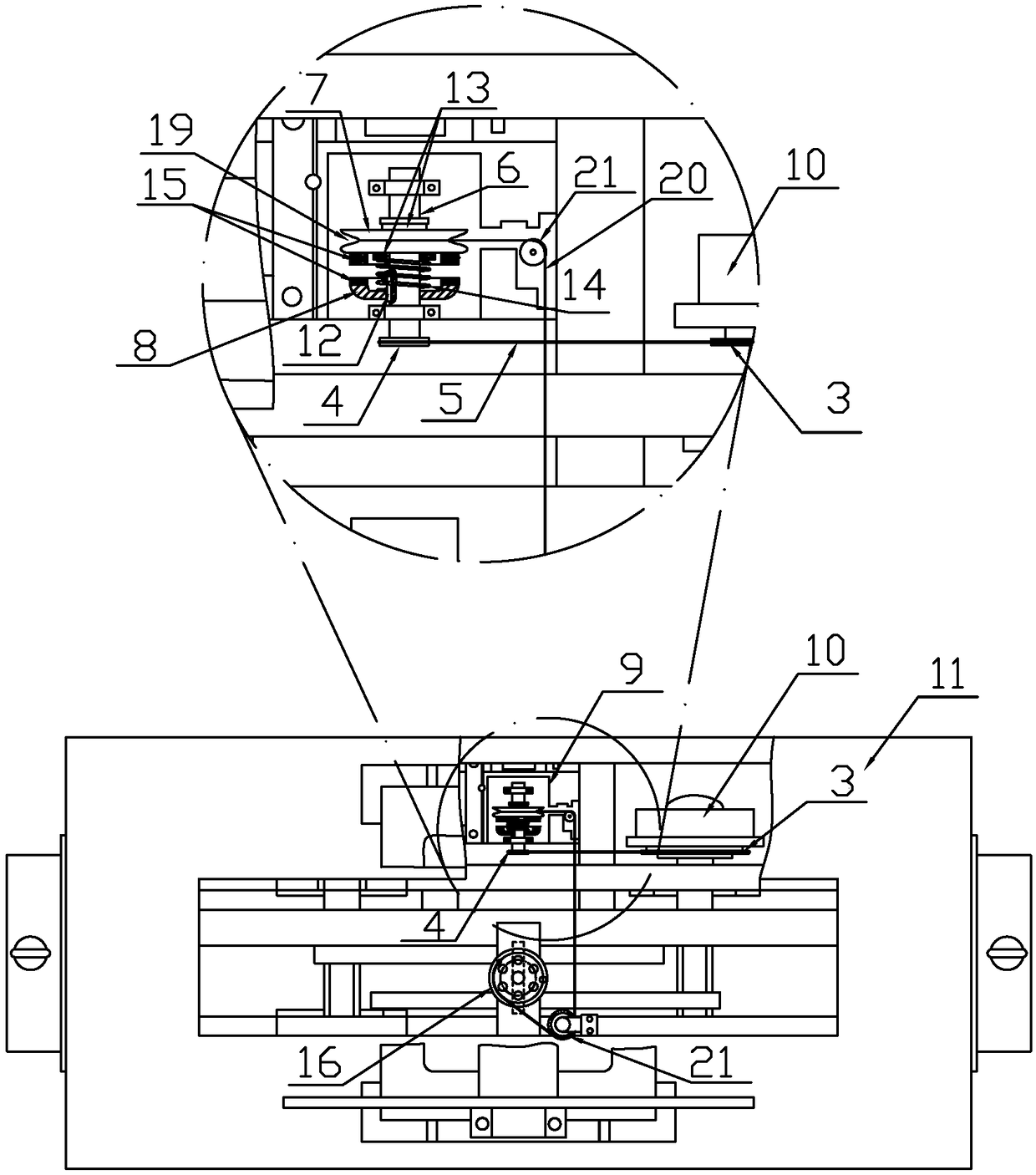

[0017] Implementation mode one: if figure 1 As shown, the overspeed automatic braking system of the infinite rope winch for mining includes a braking mechanism, and the braking mechanism includes two claws 1, and the two claws 1 are located between the two axles 2 below the winch compartment, and the two claws The outer ends of the claws 1 are respectively hinged on the vehicle frame 11 equipped with a winch.

[0018] It is characterized in that it includes a two-way centrifugal overspeed clutch brake trigger device, the two-way centrifugal overspeed clutch brake trigger device includes a large sprocket 3, a small sprocket 4, a chain 5, a rotating shaft 6, a static disc 7, a moving disc 8 and a housing 9. The large sprocket 3 is fixed on the inner side of a wheel 10 equipped with a winch, and the axis line of the large sprocket 3 coincides with the axis line of the corresponding wheel 10, and the housing 9 is fixed on the vehicle frame 11 equipped with a winch. The rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com