Automobile integrated brake-by-wire system

A technology of integrated lines and wheel brakes, applied in the direction of brakes, brake transmissions, vehicle components, etc., can solve the problems of high production cost and large occupied space, achieve low production cost, reduce occupied space, and improve modularization degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

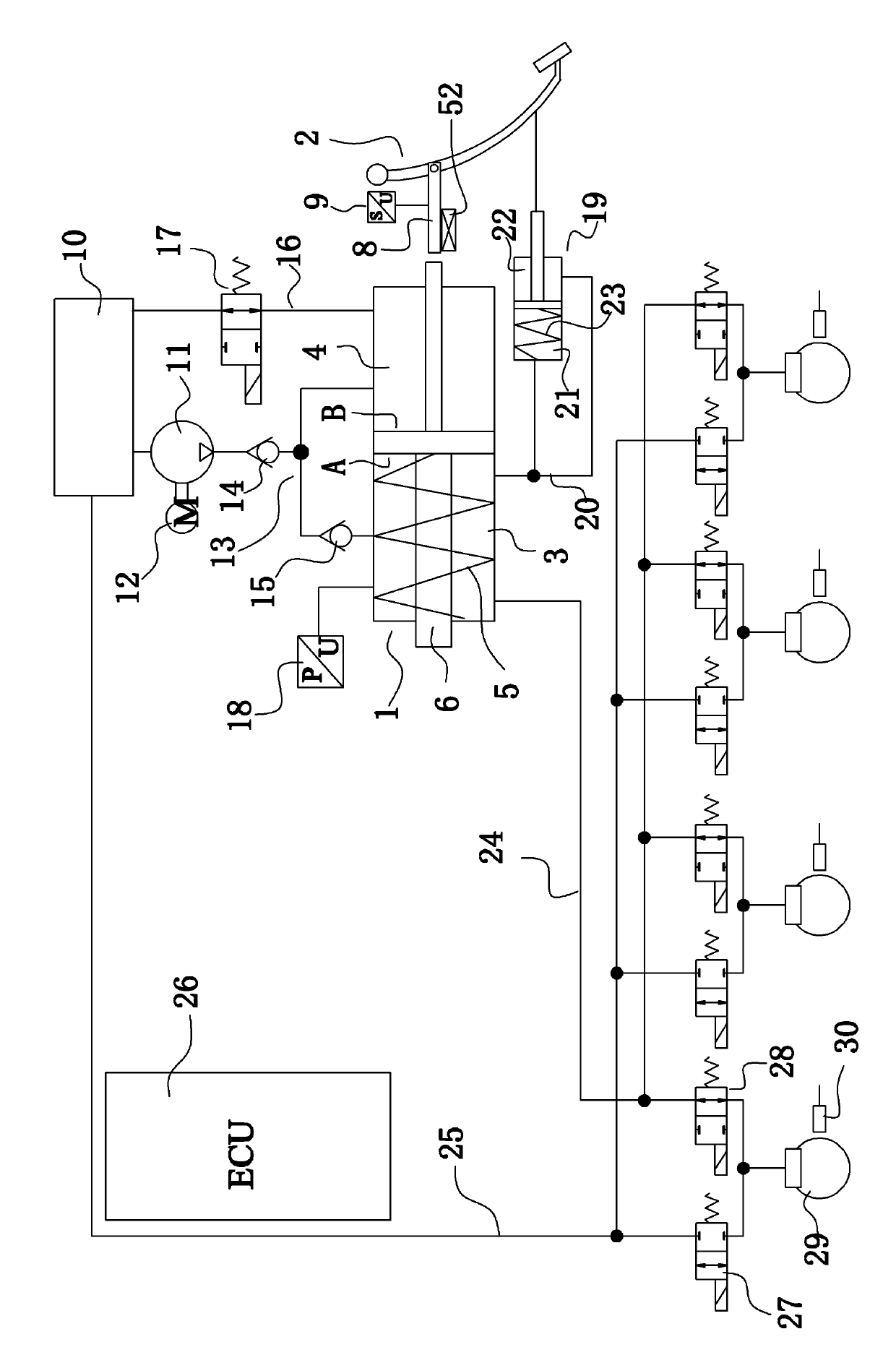

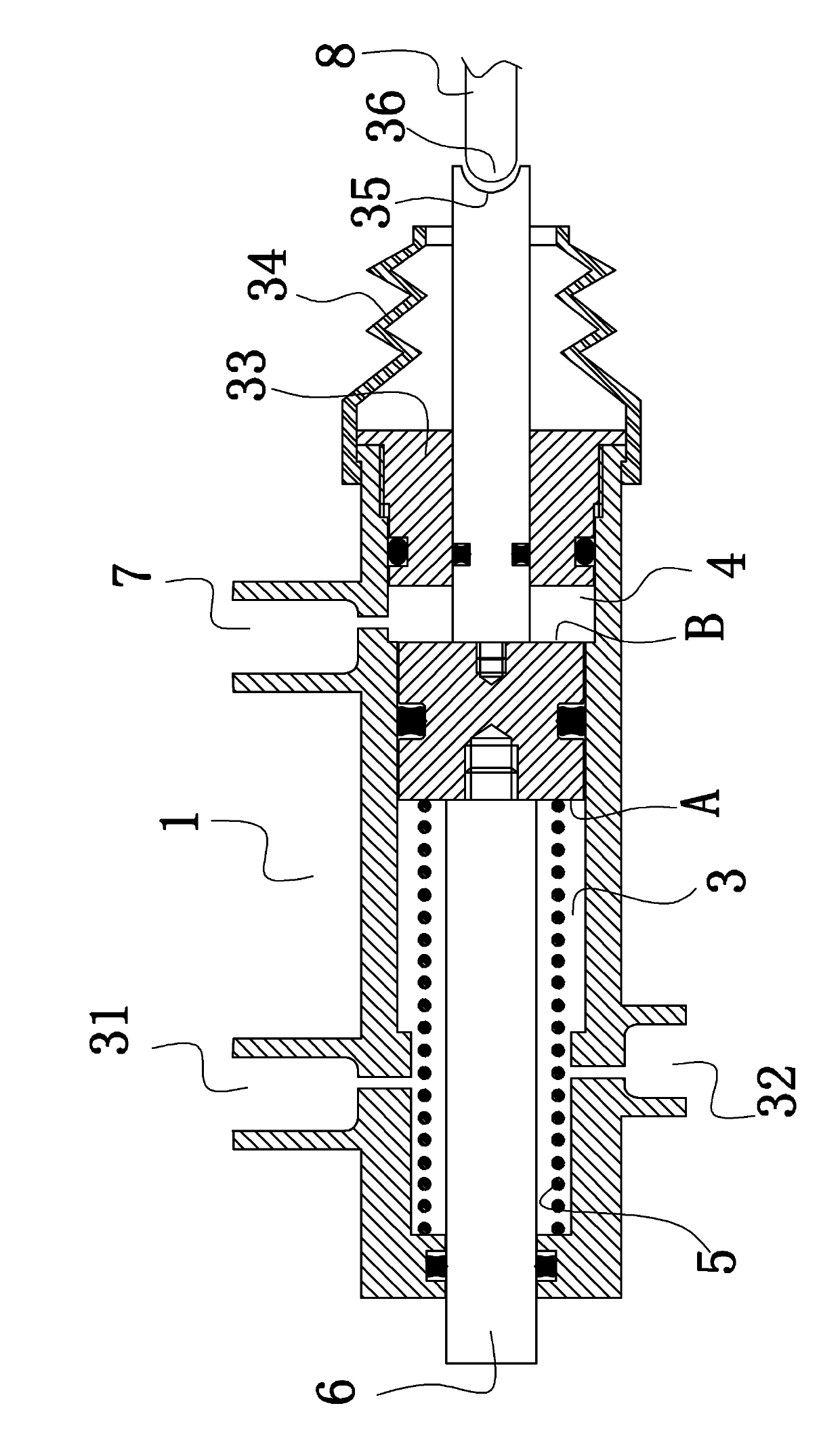

[0035] Embodiment 1: as figure 1 As shown, an automobile integrated brake-by-wire system includes an electronic control unit 26, a brake fluid tank 10, a motor 12, a pump 11, a brake master cylinder 1, a brake pedal 2, a wheel brake 29 and a The speedometer 30. A stroke sensor 9 is arranged on the brake pedal 2 . Both sides of the piston on the master brake cylinder 1 are provided with a working chamber 3 and a fluid replenishing chamber 4 . A first return spring 5 is arranged in the working chamber; a pressure sensor 18 for detecting the pressure of the working chamber is arranged on the working chamber.

[0036] A first brake passage 24 connects the brake master cylinder 1 and the wheel brake 29 . The first brake passage 24 includes a first main passage connected to the working chamber 3 and first branch passages respectively connected to the wheel brakes 29 . The first brake passage 24 is provided with a first electromagnetic switch valve 28; specifically, each first br...

Embodiment 2

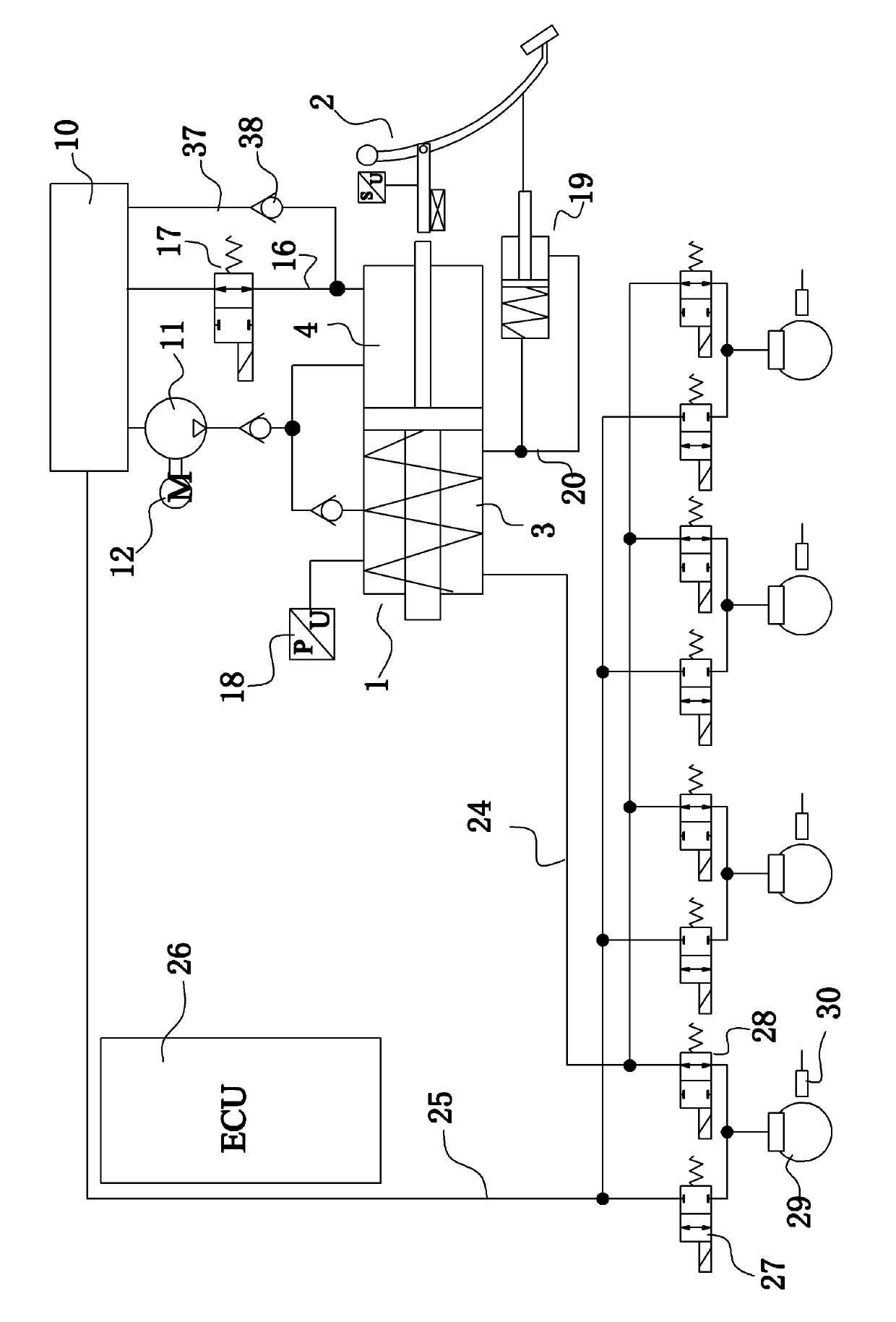

[0048] Embodiment 2: as image 3 As shown, a sixth brake passage 37 is provided between the brake fluid tank 10 and the brake master cylinder 1 , which connects the brake fluid tank 10 and the liquid replenishing chamber 4 . The sixth brake passage 37 is provided with a first one-way valve 38 through which the brake fluid can flow from the brake fluid tank to the liquid replenishing chamber. Refer to Embodiment 1 for the rest of the structure of this embodiment.

[0049] When the brake-by-wire system breaks down, specifically, when the electronic control unit 26 works normally but the motor 12 or the pump 11 breaks down, conventional hydraulic braking can be realized through the cooperation of the sixth brake passage 37 and the first one-way valve 38. At the same time, when the brake-by-wire system works normally, it will not affect the brake-by-wire. Since the flow direction of the first one-way valve 38 is from the brake fluid tank to the liquid replenishment chamber, the ...

Embodiment 3

[0050] Embodiment 3: as Figure 4 , Figure 5 As shown, one end of the brake master cylinder 1 is provided with an energy storage chamber 39 and the energy storage chamber communicates with the working chamber 3 . The energy storage cavity 39 is provided with a piston and an energy storage spring 51 . The energy storage chamber 39 communicates with the working chamber 3 through a plurality of guide holes 50 . The guide rod arranged on the piston of the brake master cylinder passes through the working chamber 3 and the energy storage chamber 39 and is located outside the brake master cylinder, and a sealing ring is arranged between the guide rod and the cylinder body of the brake master cylinder. The distance L between the first fluid replenishment hole 7 of the brake master cylinder and the inner end surface of the sealing end cover 33 is greater than the piston thickness of the brake master cylinder.

[0051] Such as Figure 4 As shown, the first brake passage 24 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com