Reduction device and process for efficiently producing polycrystalline silicon

A polysilicon and process technology, which is applied in the field of reduction devices for efficient production of polysilicon, can solve problems such as worn valves and pipeline blockages, and achieve the effects of reducing unit power consumption, improving efficiency, and increasing deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention is not limited to the scope described in the embodiments.

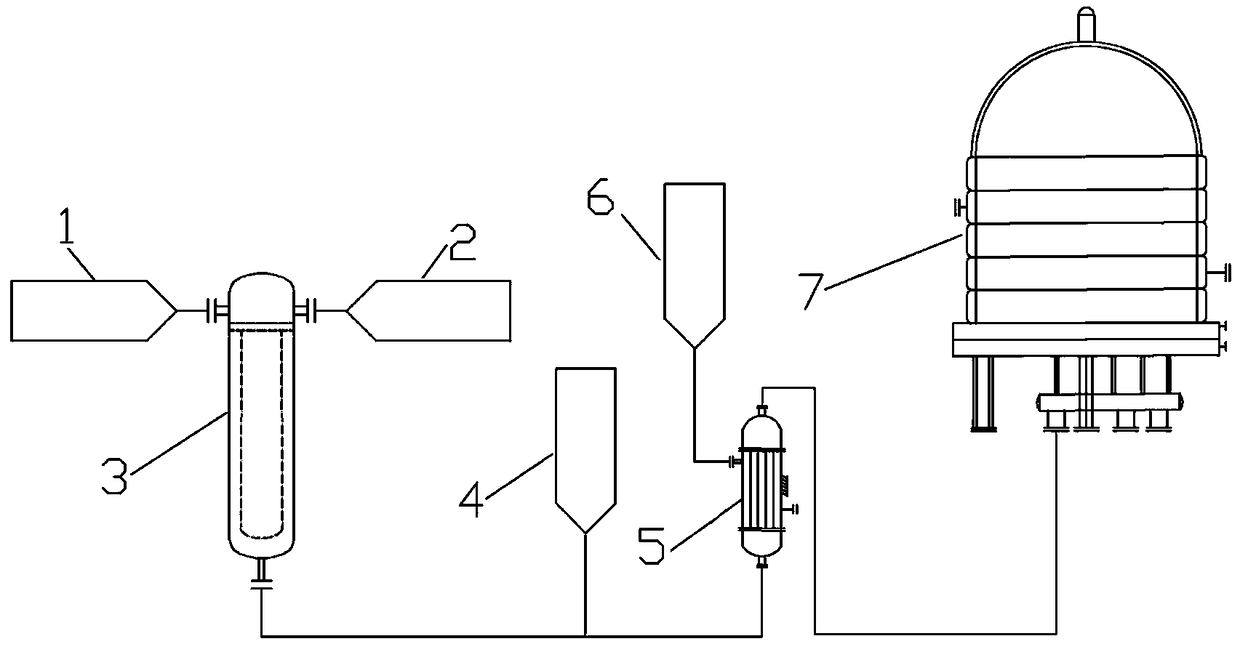

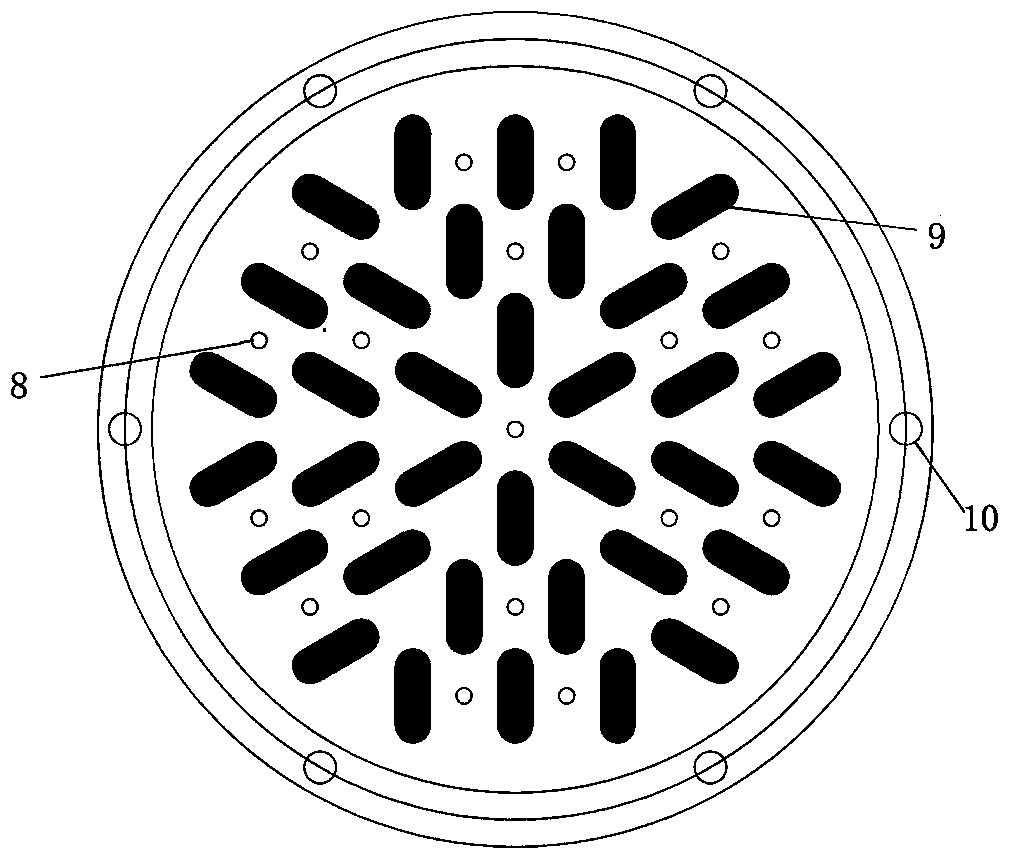

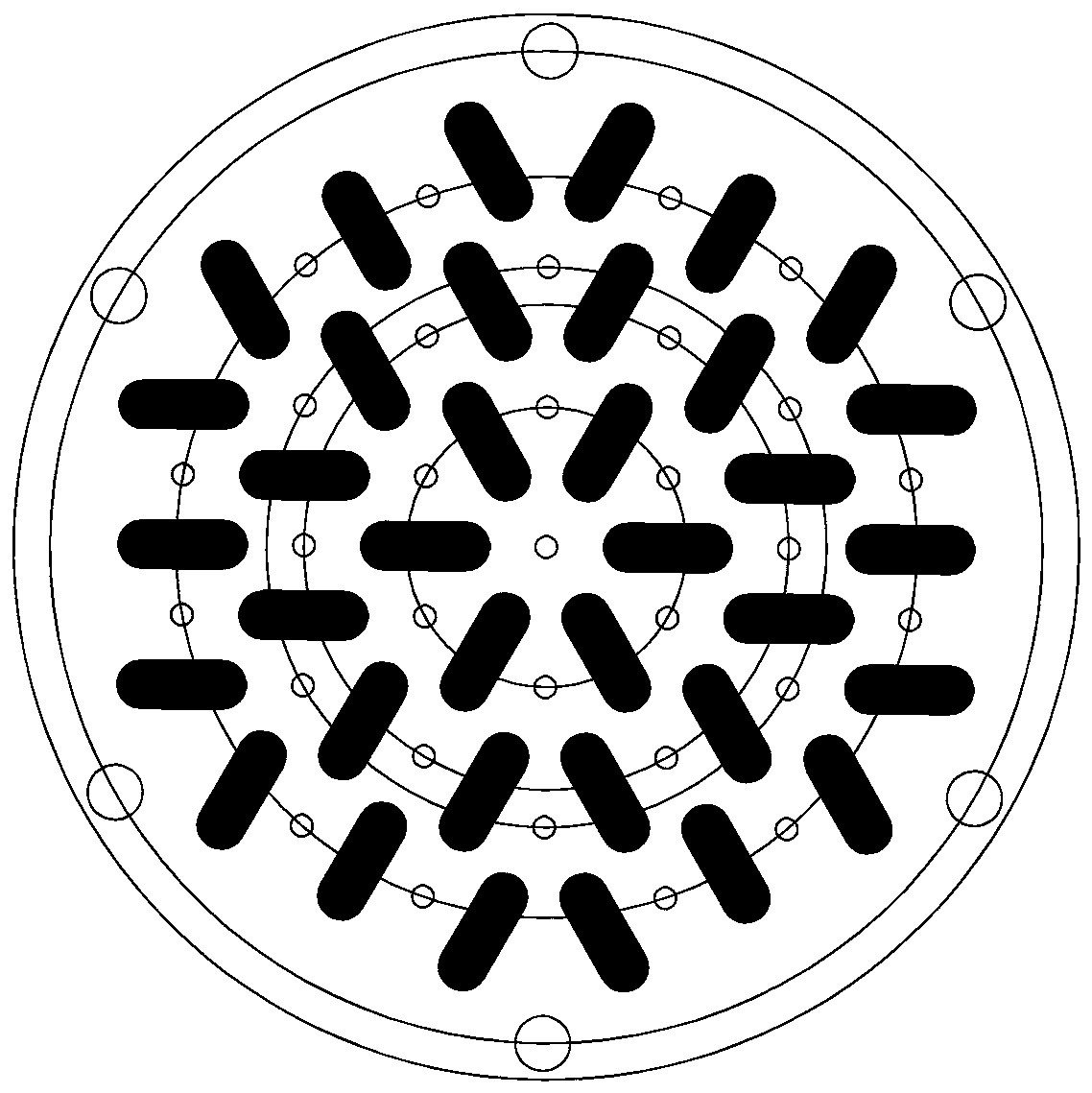

[0030] Such as Figure 1-Figure 2As shown, a reduction device for efficiently producing polysilicon includes a material mixing system, a material vaporization system and a system for reducing and generating polysilicon connected in sequence; wherein the material mixing system includes a trichlorosilane feed system 1, a dichlorodihydrosilane feed system material system 2 and material mixer 3; the material vaporization system includes a steam heating system 6 and a material vaporizer 7; a hydrogen feed system 4 is also provided between the material mixer 3 and the material vaporizer 7; the reduction system for producing polysilicon includes a reduction furnace, The reduction furnace includes a chassis and a furnace cylinder, wherein the chassis has ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap