Boundary noise continuous monitoring system capable of self-calibration for substation

A technology of factory boundary noise and monitoring system, applied in measurement devices, measurement of ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of high equipment cost, high maintenance cost, background noise interference, etc., to save manpower, low cost, The effect of improving reliability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

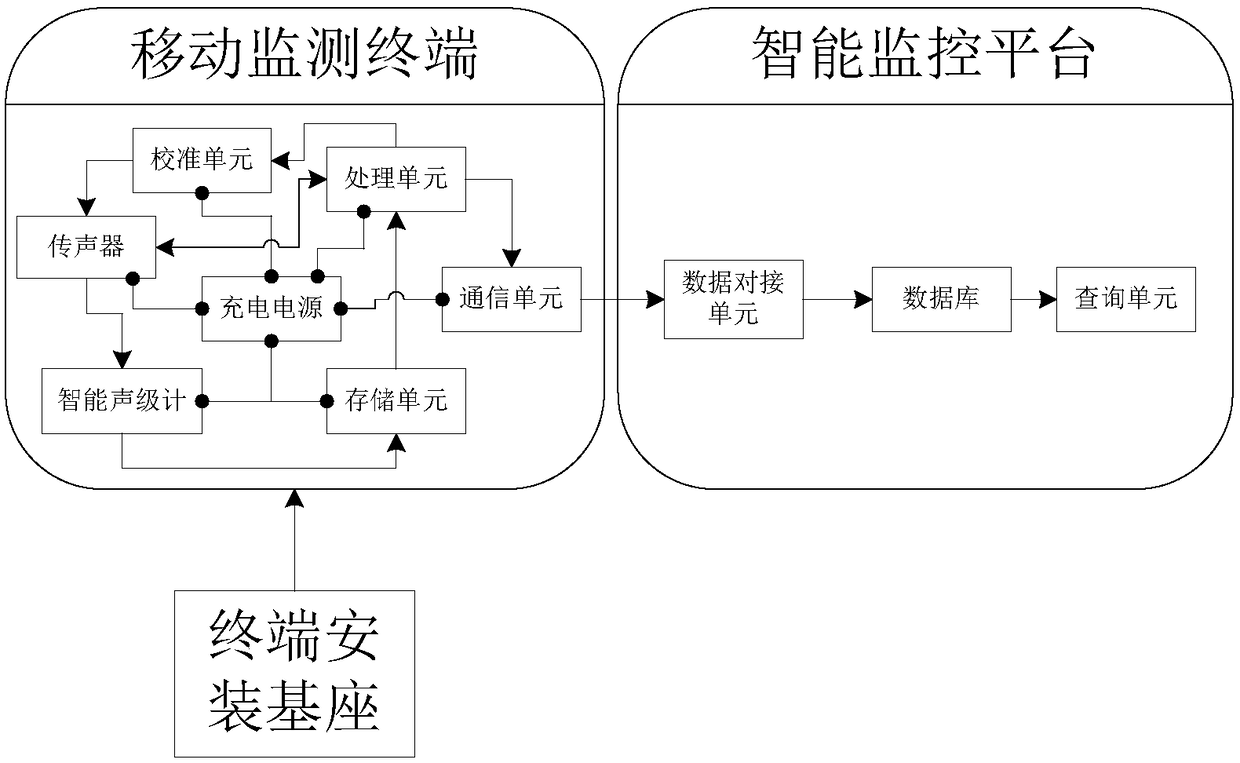

[0030] Such as figure 1 As shown, the self-calibrating continuous monitoring system for substation boundary noise includes a mobile monitoring terminal, a terminal installation base and an intelligent monitoring platform. The mobile monitoring terminal includes a microphone, an intelligent sound level meter, a storage unit, a processing unit, and a calibration unit , a communication unit and a rechargeable power supply, the intelligent monitoring platform includes a data docking unit, a database and a query unit, wherein:

[0031] There are several terminal installation bases, which are distributed at various monitoring points around the substation according to the cross point method, and the mobile monitoring terminal is detachably installed on the terminal installation base;

[0032] The communication unit and the data docking unit establish a remote signal connection, which jointly acts on the signal transmission between the mobile monitoring terminal and the intelligent mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com