Backlight module, manufacturing method thereof and display device

A technology for a backlight module and a manufacturing method, which is applied in the directions of electrical components, electrical solid-state devices, circuits, etc., can solve problems such as bad gypsophila

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] As mentioned in the background technology section, in the prior art, the backlight module formed by Mini LED is prone to starry sky phenomenon during the display process.

[0036] The reason that inventor finds above-mentioned phenomenon occurs is:

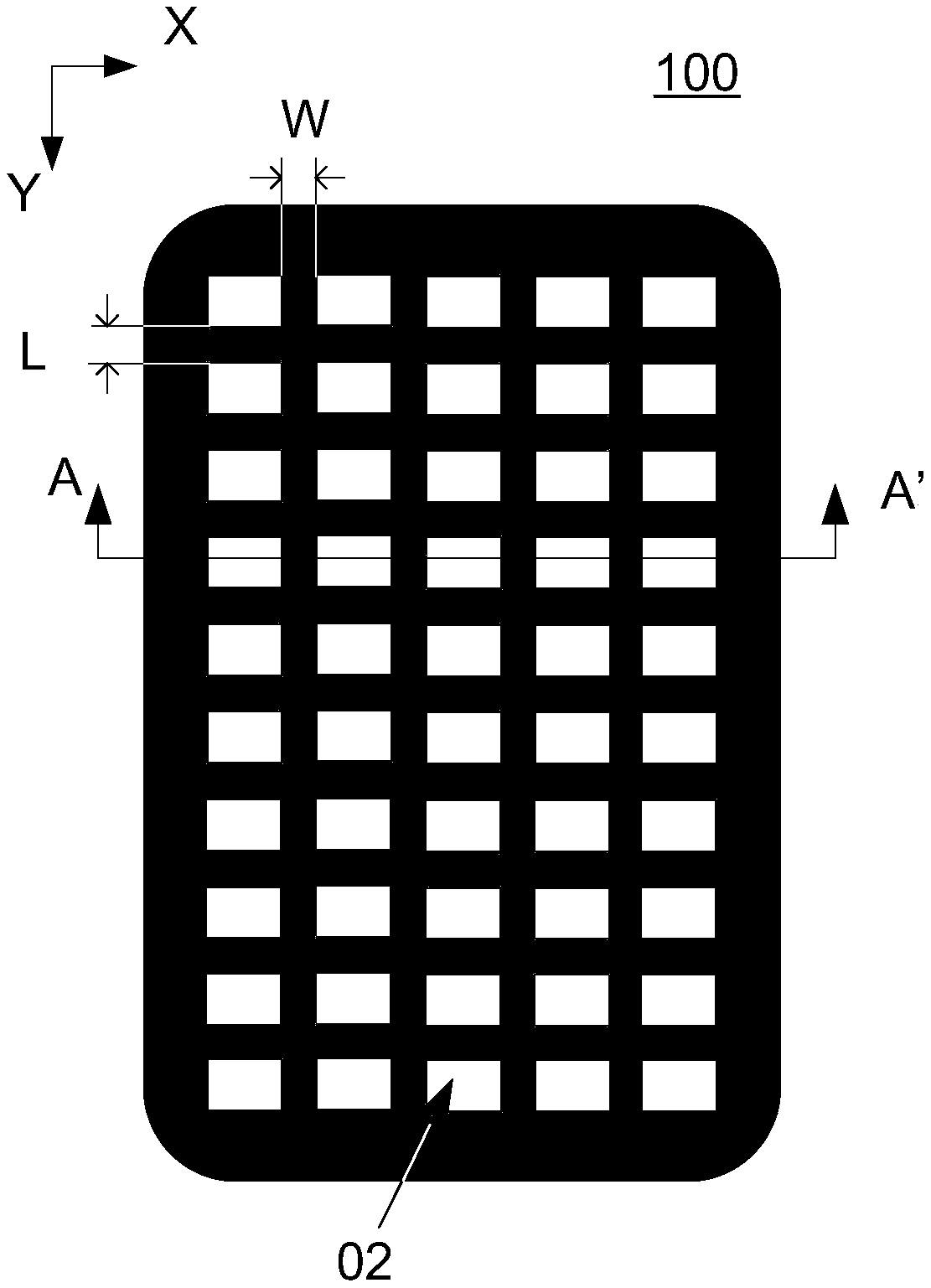

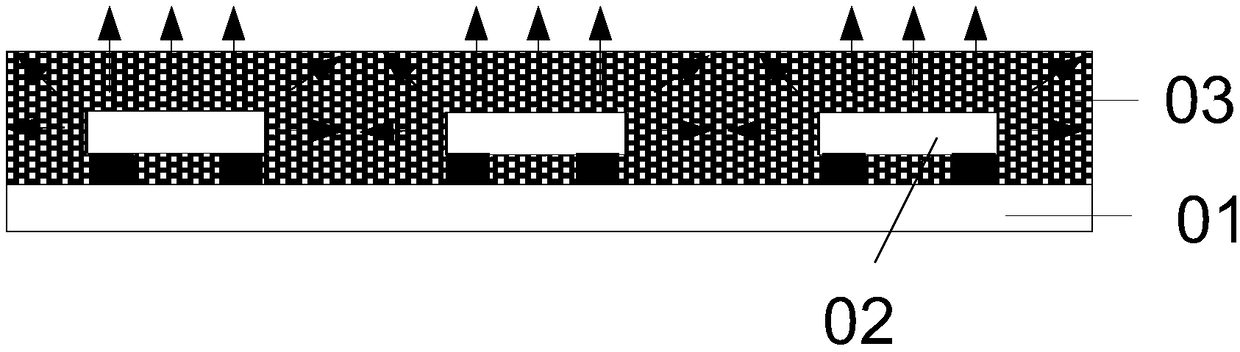

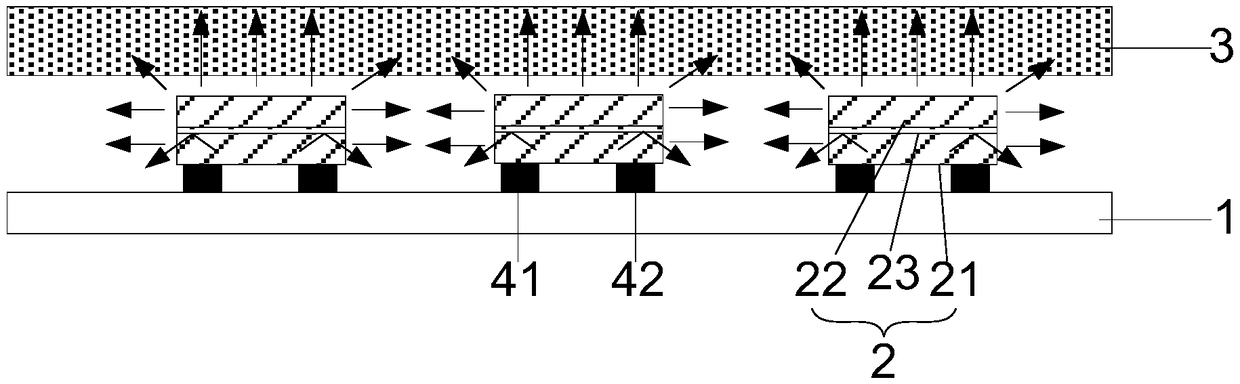

[0037] See figure 1 , figure 1 A schematic diagram of the top view structure of a display device provided for the prior art; in the display device 100, there will be a certain distance between adjacent LED chips 02, for example, there is a first gap between two adjacent LED chips 02 in the X direction. The spacing W, and the second spacing L between two adjacent LED chips 02 in the Y direction. See figure 2 , figure 2 for along figure 1 The cross-sectional schematic diagram of the backlight module of the line AA' in the middle; wherein, the LED backlight module includes a PCB board 01, a number of LED chips 02 are arranged on the PCB board 01, a fluorescent film 03 is arranged on the LED chip 02, and the light emitti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com