Method for defect-free copper filling of hole in part carrying member and plating device

A component-carrying, unfilled technology, applied in the processing of printed circuit components, electrical components, insulating substrates/layers, etc., can solve problems such as ineffective operation, poor performance, and irregular growth process of copper material 310, To achieve the effect of saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

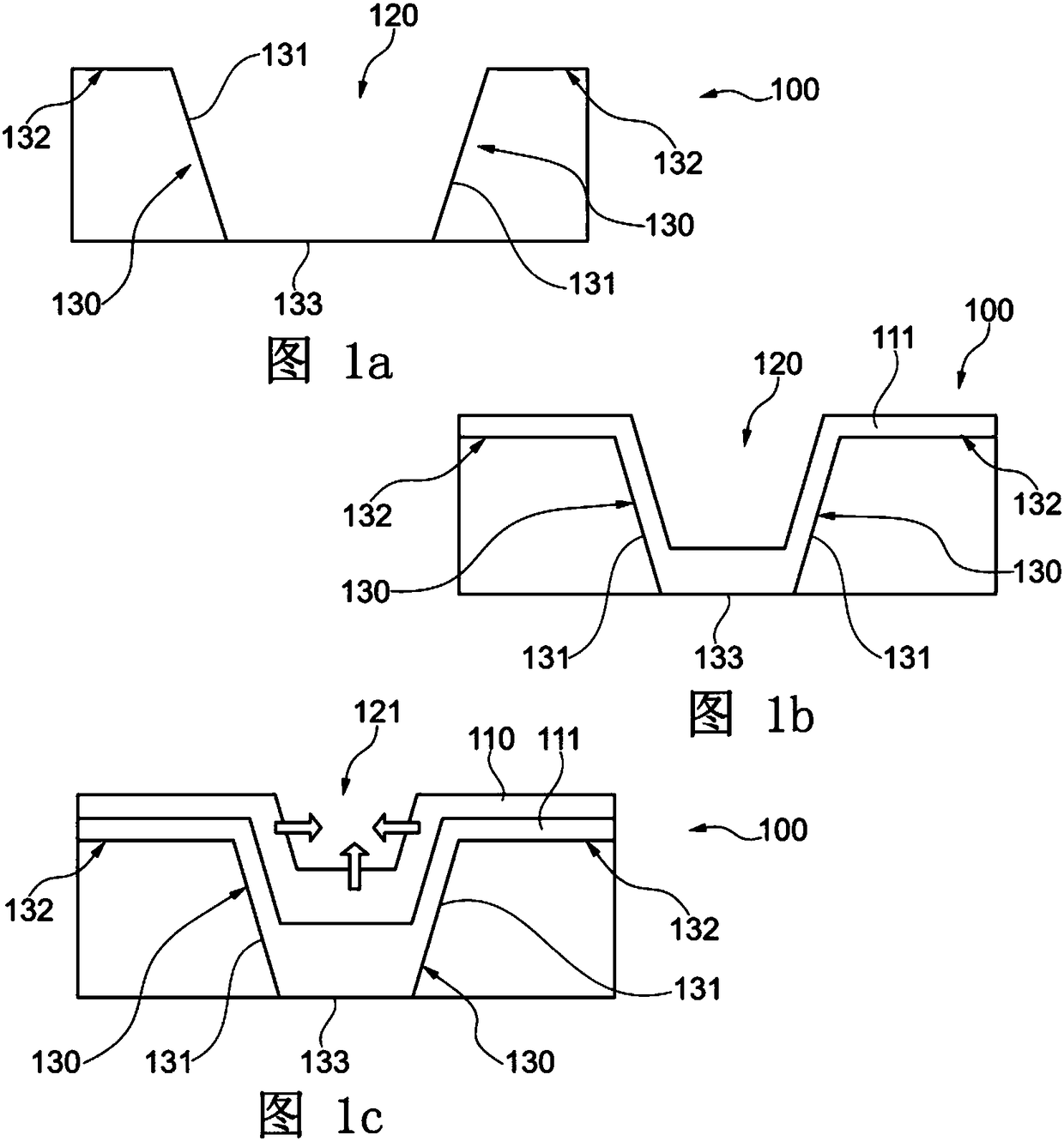

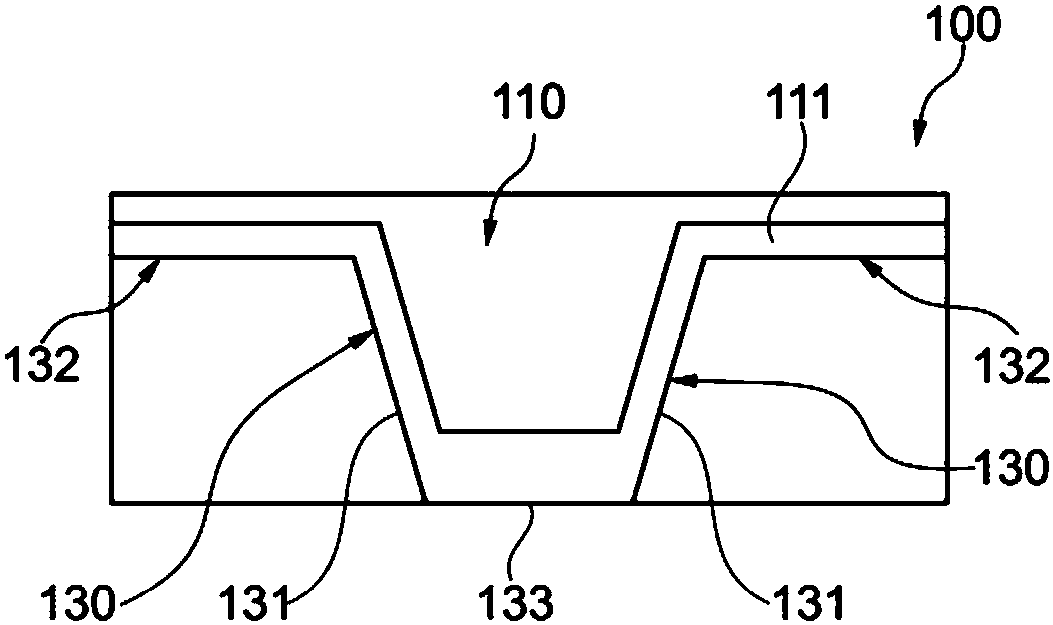

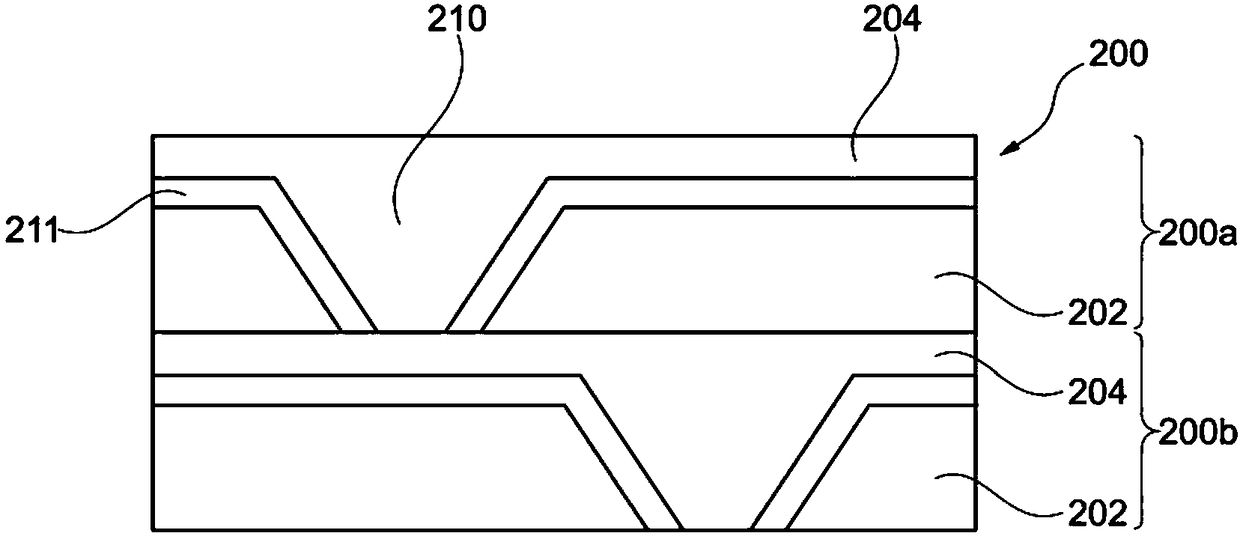

[0075] Before describing the exemplary embodiments in more detail with reference to the drawings, some basic considerations on the basis of which the exemplary embodiments of the present invention have been arrived at will be summarized.

[0076] According to an exemplary embodiment of the invention, the filling capacity of the holes in the component carrier is increased and a better reliability of the component carrier, in particular of the PCB, is achieved with regard to function. Usually, the concentration of copper ions in the plating environment is around 35g / L. On the one hand, when the concentration is lower, the formation of defects such as cracks increases. On the other hand, when the copper concentration is too high, not all of the copper is soluble anymore, and crystallization of copper occurs. Copper concentrations in the high range of 50 g / L to 80 g / L, especially about 65 g / L would not be considered appropriate in a plating environment due to the increased likeli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com