Sugarcane semi-automatic peeling machine

A semi-automatic, peeling machine technology, applied in the peeling of vegetables or fruits, food science, applications, etc., can solve the problems of high failure rate, high equipment cost, and inability to effectively adapt to sugarcane peeling of various specifications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

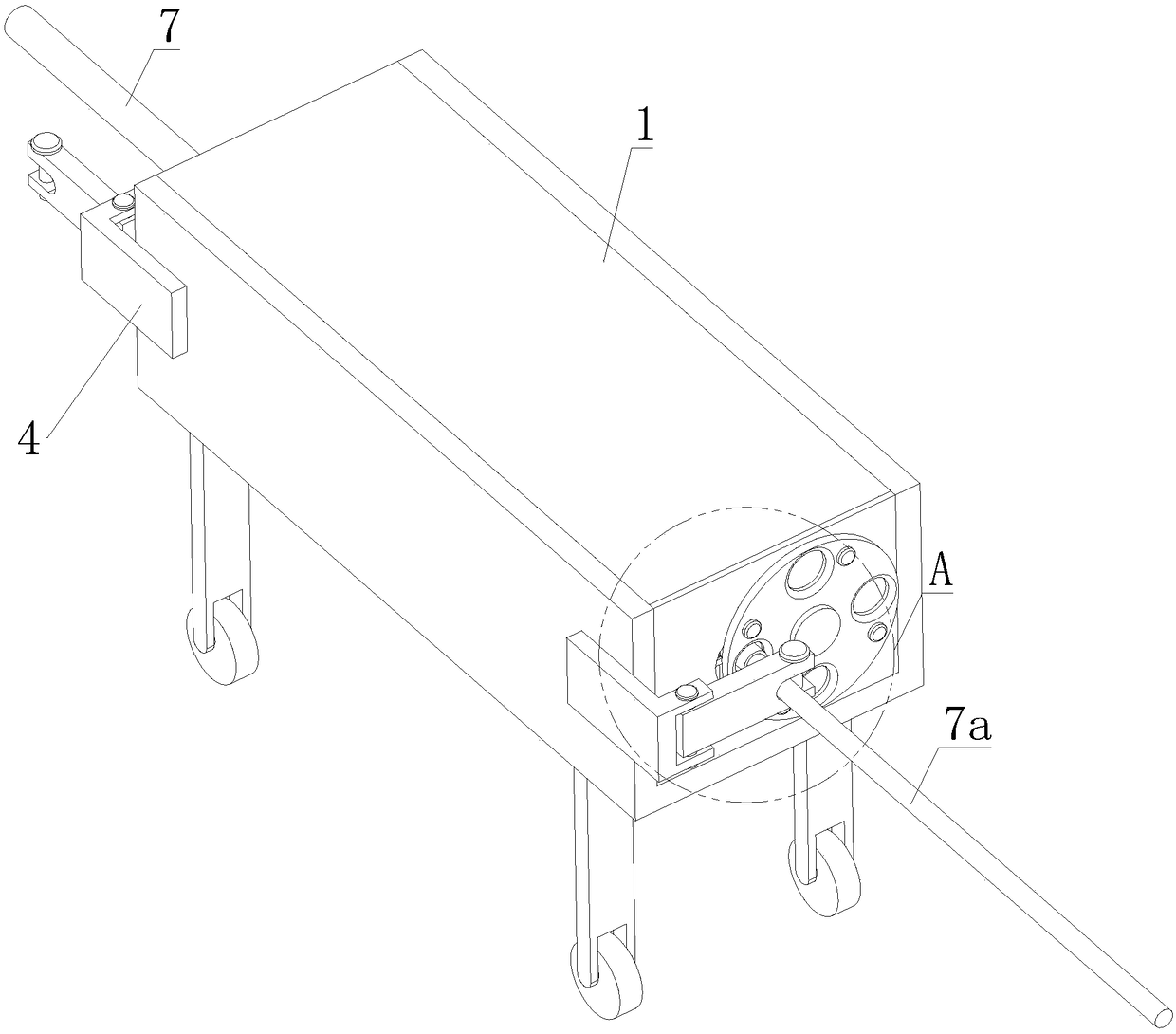

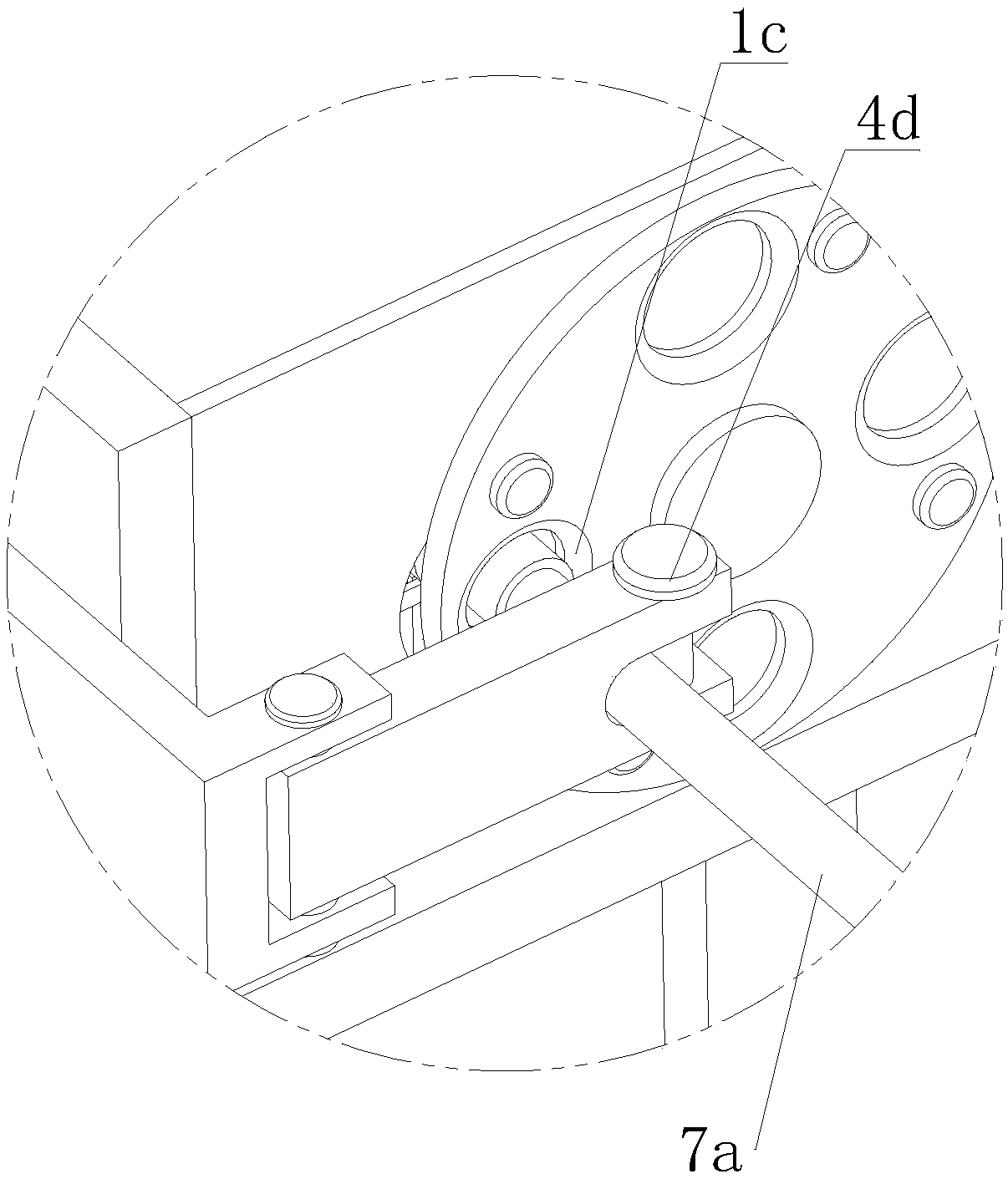

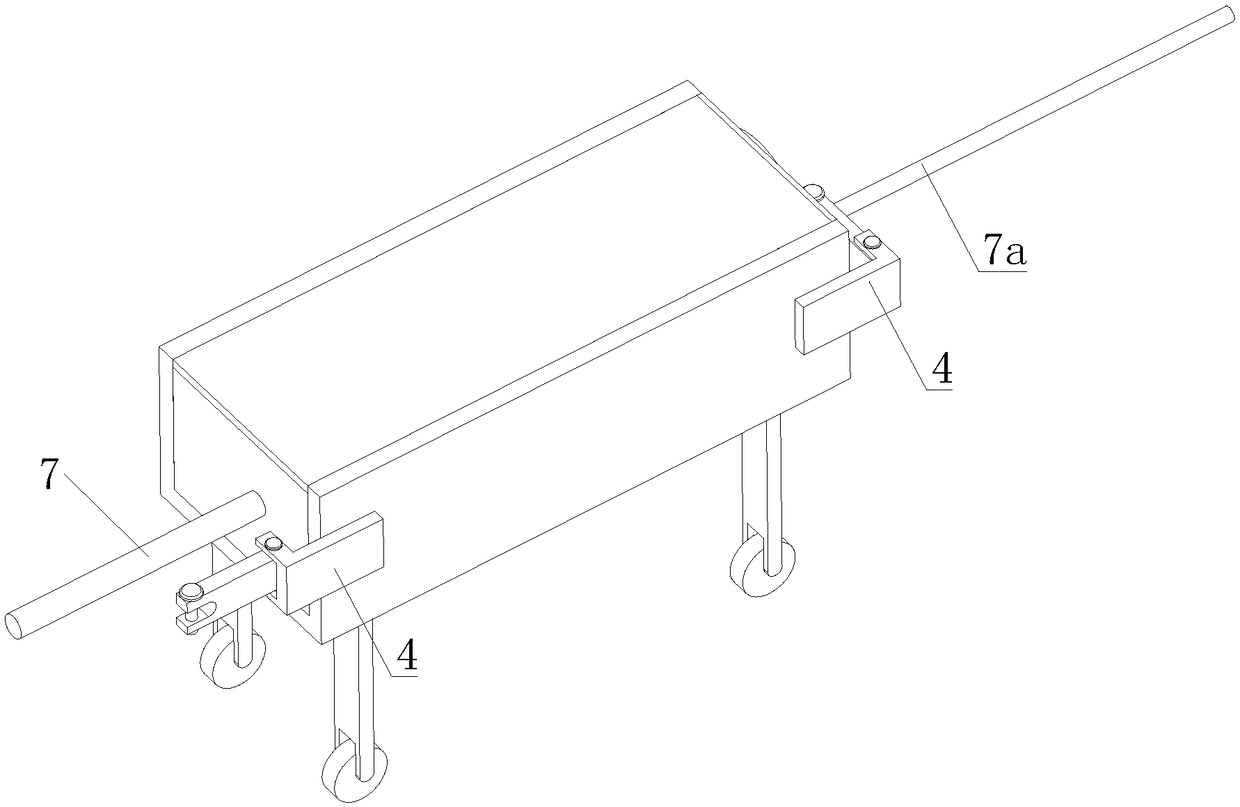

[0038] refer to Figure 1 to Figure 11 A sugarcane semi-automatic peeling machine shown includes a body 1, a peeling assembly 2, an adjustment assembly 3, two auxiliary propulsion assemblies 4 and at least two support assemblies 5 with the same structure, and the peeling assembly 2 includes symmetrical installation up and down. The two peeling knives 2a inside the body 1, the two peeling knives 2a can be passively set towards or back to each other through an elastic member, and the adjustment assembly 3 is installed inside the body 1 and used to drive the two elastic members to face each other Or back to the movable setting, two supporting components 5 are respectively arranged at the left and right ends of the body 1, two auxiliary propulsion components 4 are respectively located at the left and right ends of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com