Medicine extraction equipment

A technology for extracting equipment and medicines, which is applied in grain processing, food science, solid solvent extraction, etc., and can solve problems such as inability to extract in large quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

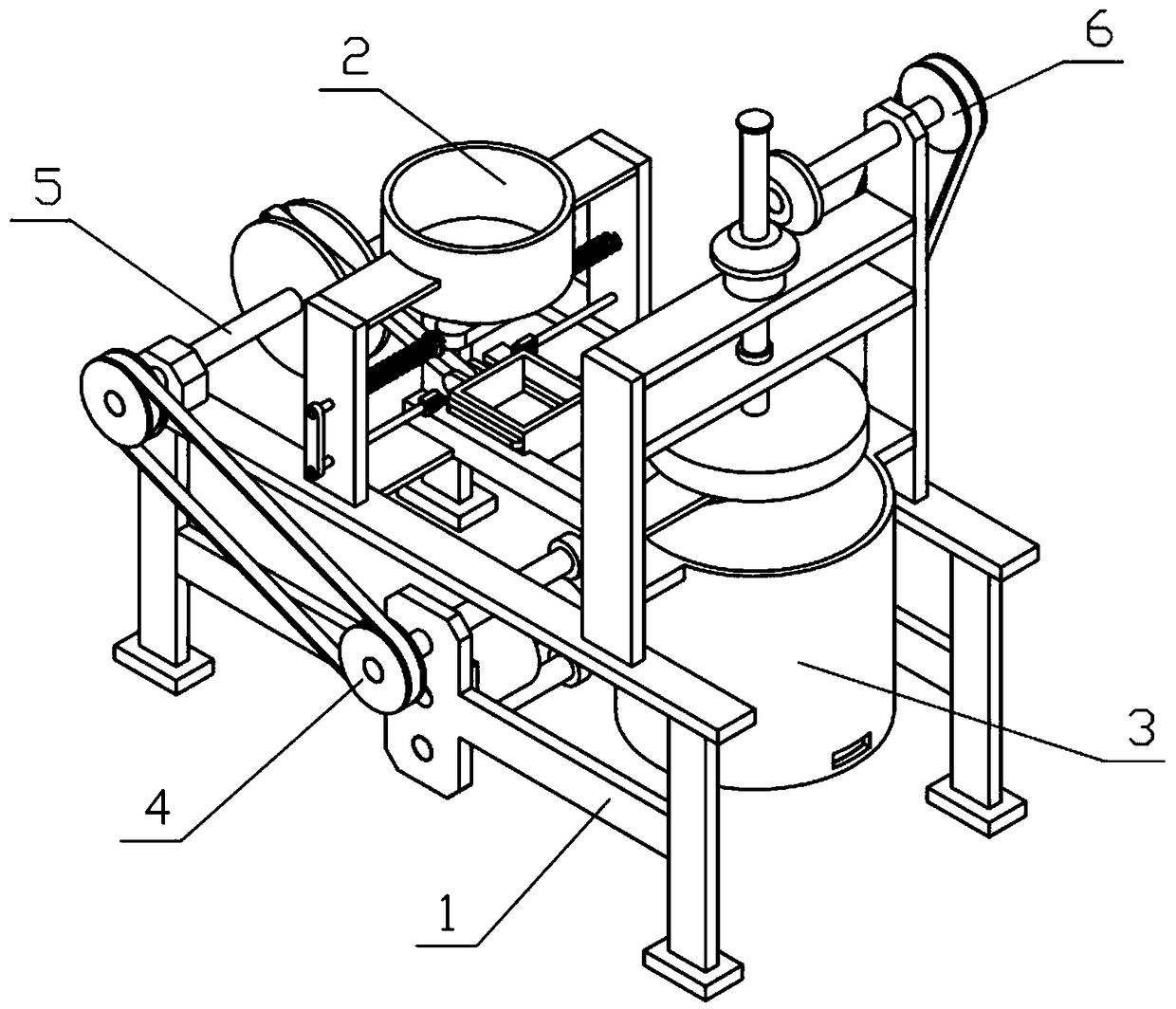

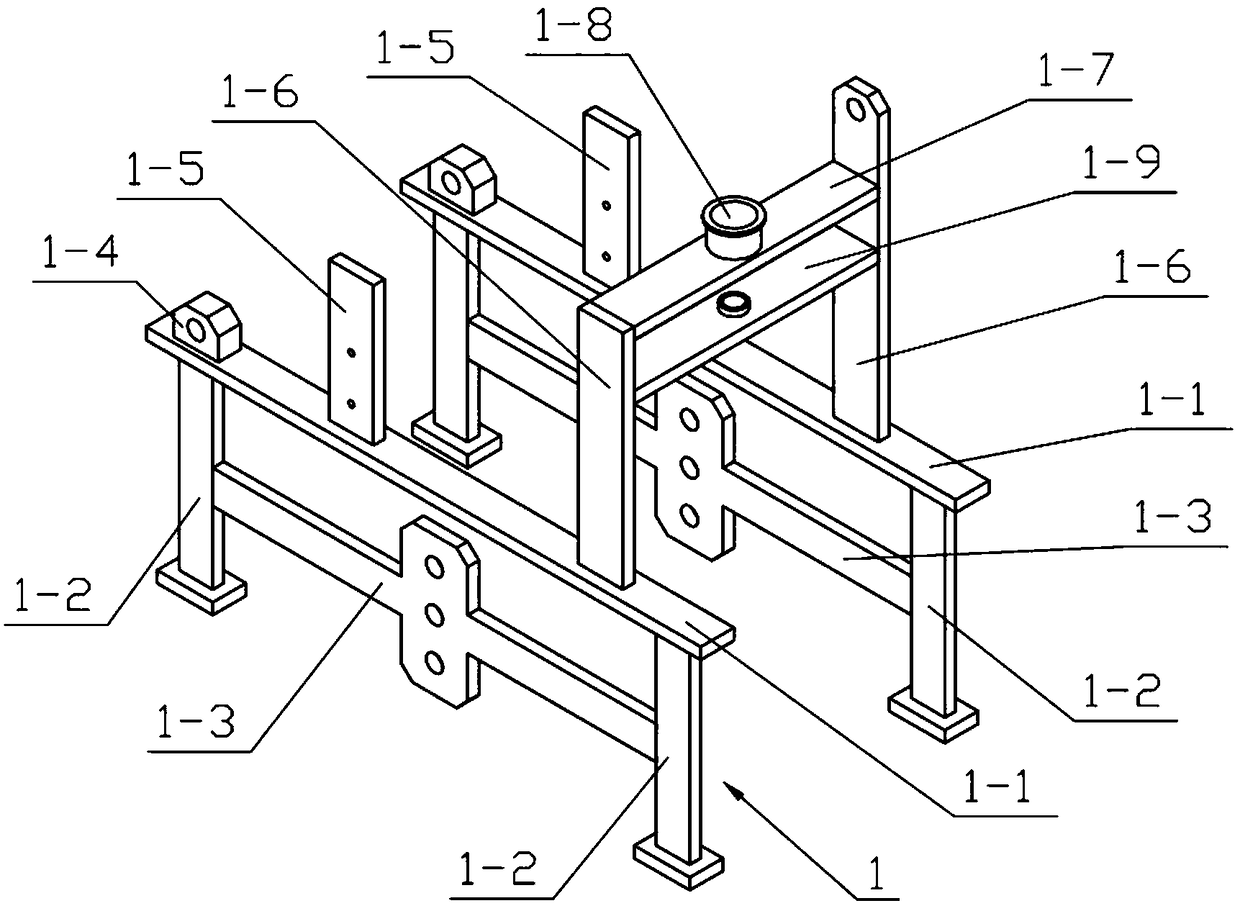

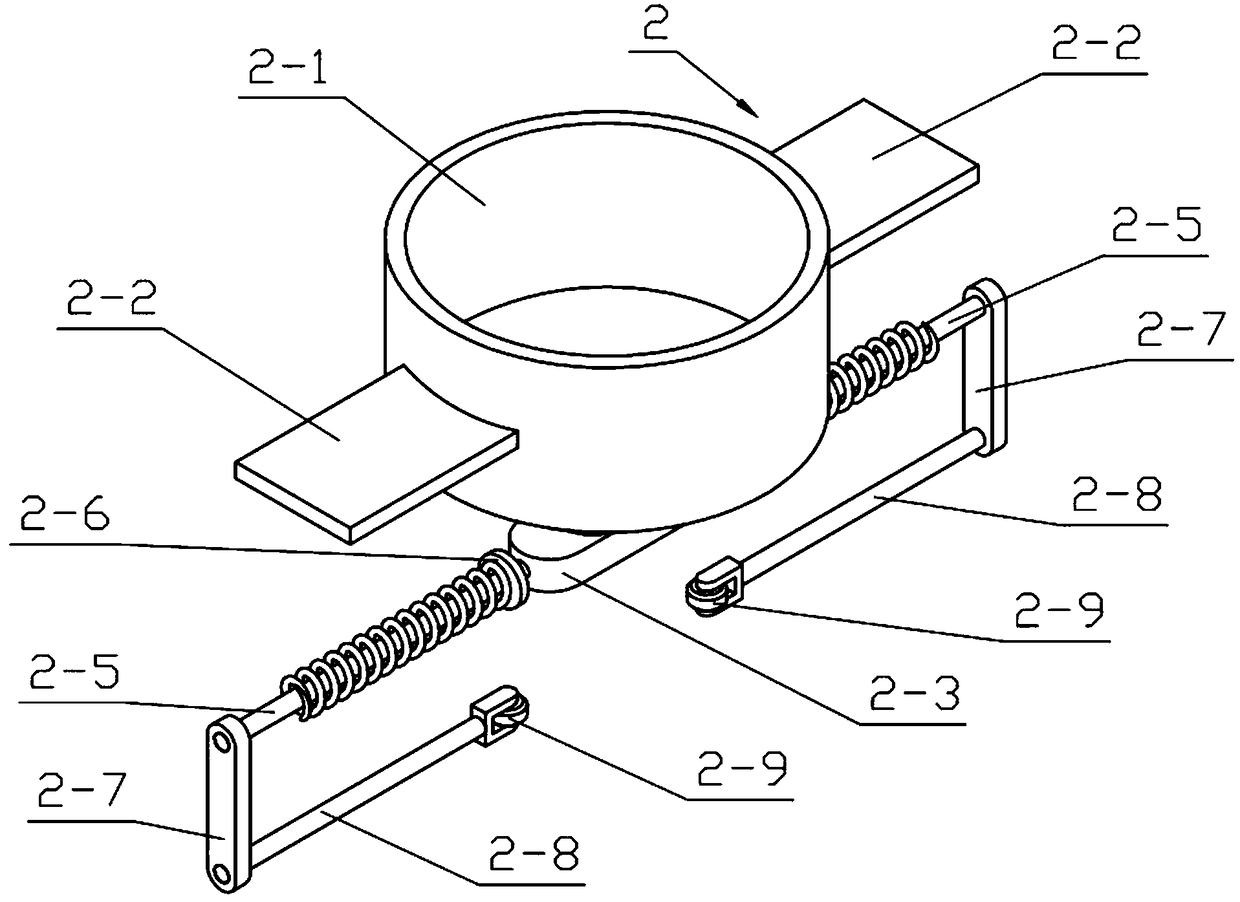

[0031] Combine below Figure 1-10 Describe this embodiment, a kind of drug extraction equipment, including extraction bracket 1, feeding mechanism 2, crushing bracket 3, power mechanism 4, feeding mechanism 5 and crushing mechanism 6, can pass toothless gear 4- 2. The power gear II4-7 and power gear I4-4 realize the intermittent motion of the feeding mechanism 5 and the crushing mechanism 6, and the diameter of the indexing circle of the tooth-missing gear 4-2 is the power gear II4-7 and the power gear I4-4. Twice the diameter of the circle, when the tooth-missing gear 4-2 rotates one revolution, the feeding mechanism 5 and the crushing mechanism 6 work for one cycle. When the feeding mechanism 5 moves, the medicinal materials placed in the discharge barrel 2-1 are transported to the crushing barrel In 3-1, when the crushing mechanism 6 moves, the medicinal materials in the crushing cylinder 3-1 are squeezed and crushed so that the liquid and residue in the medicinal materials...

specific Embodiment approach 2

[0038] Combine below Figure 1-10 Illustrate this embodiment, and this embodiment will further explain Embodiment 1, and described discharge mechanism 2 also comprises push wheel 2-9, and the inner side of two push columns 2-8 is all rotatably connected with push wheel 2-9; Push wheel 2-9 can change sliding friction into rolling friction to reduce the damage caused by friction.

specific Embodiment approach 3

[0039] Combine below Figure 1-10 Describe this embodiment, this embodiment will further explain Embodiment 2, the tooth-missing gear 4-2 is provided with half a ring of teeth, and the index circle diameter of the tooth-missing gear 4-2 is the power gear II 4-7 index Twice the diameter of the circle, the pitch circle diameters of power gear II 4-7 and power gear I 4-4 are equal; when tooth-missing gear 4-2 rotates one circle, it drives power gear II 4-7 and power gear I 4-4 to rotate one circle, When tooth-missing gear 4-2 and power gear II 4-7 mesh transmission, tooth-missing gear 4-2 and power gear I 4-4 withdraw from mesh transmission, and tooth-missing gear 4-2 and power gear II 4-7 withdraw from mesh transmission, tooth-missing gear 4-2 exits mesh transmission. Teeth gear 4-2 and power gear I 4-4 mesh transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com