Ultrasonic wave food processing device

A food processing device and ultrasonic technology, applied in metal processing and other directions, can solve the problems of bread deformation, large cutting resistance, waste of raw materials, etc., and achieve the effects of compact structure, convenient and reliable production and installation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

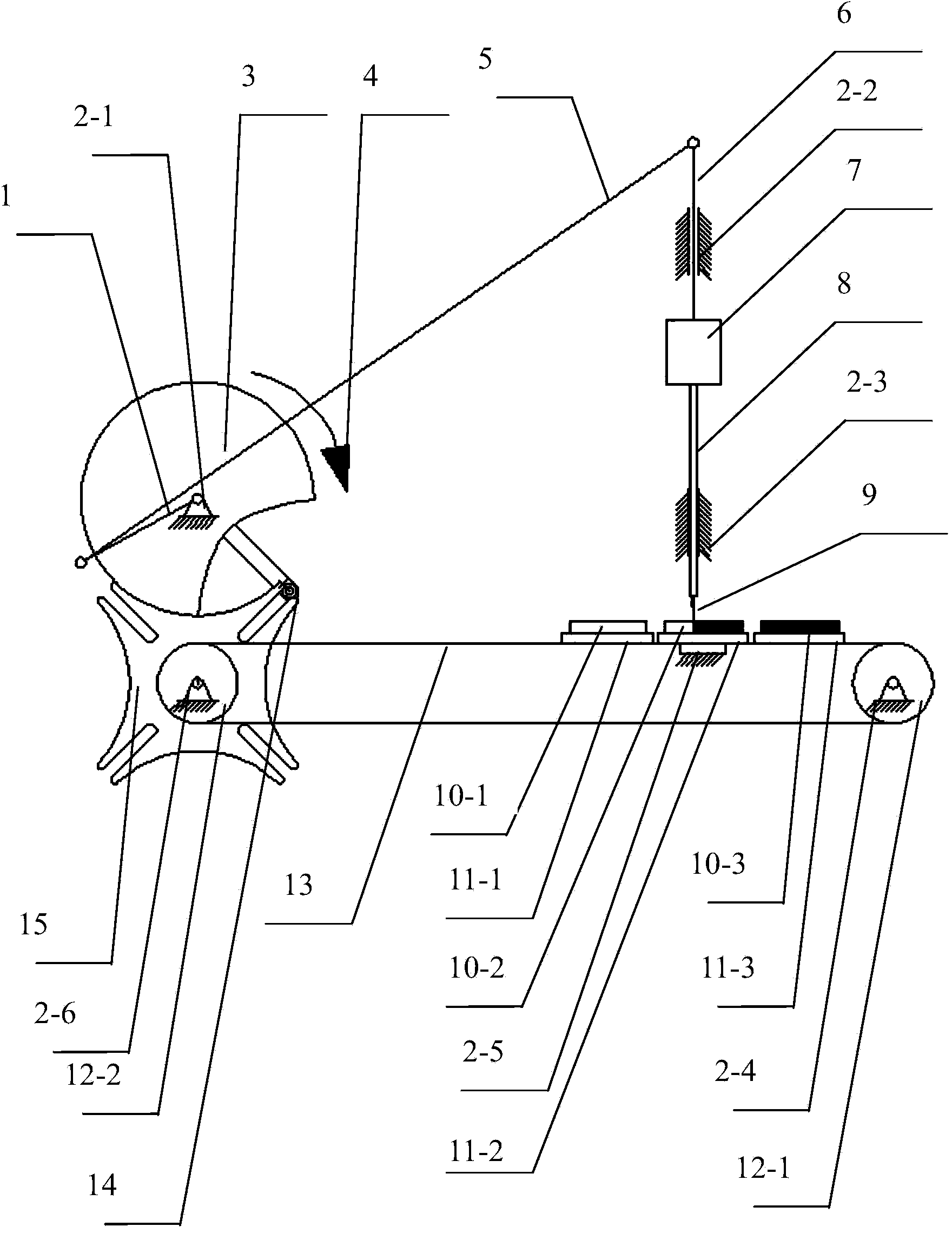

[0012] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is described further.

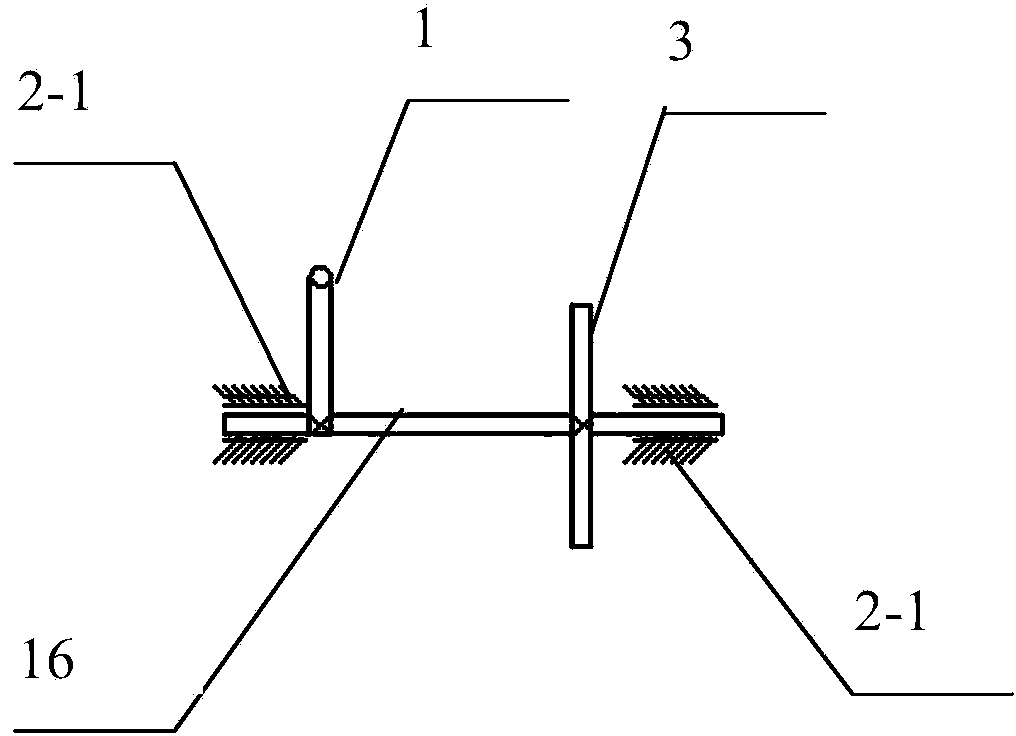

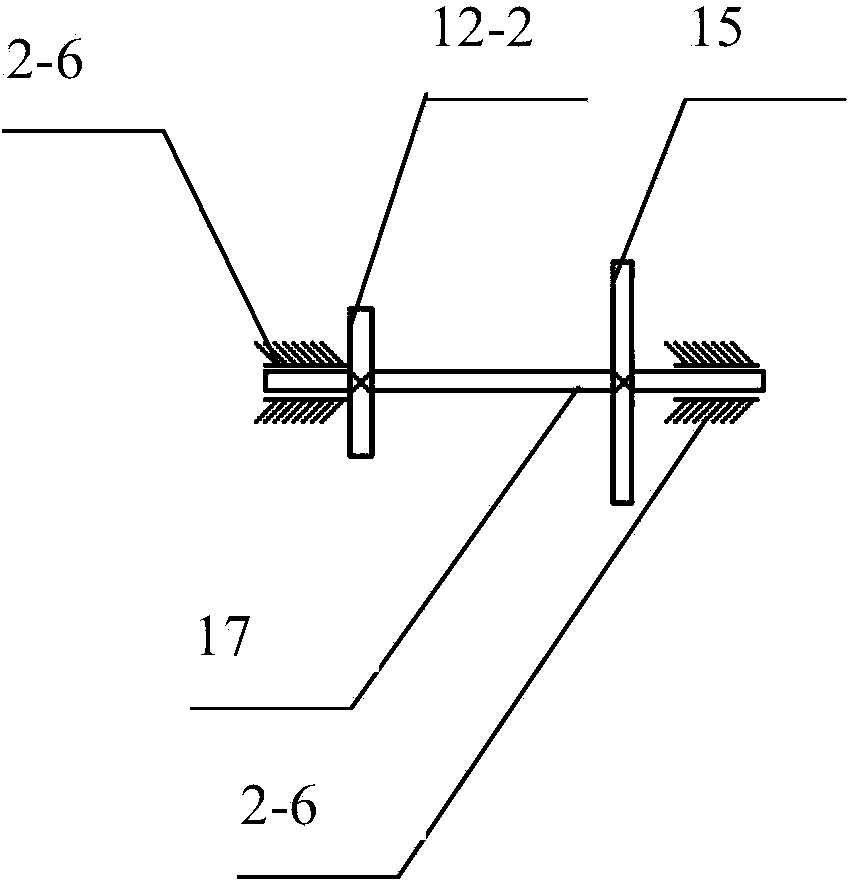

[0013] Referring to the accompanying drawings, a new ultrasonic food processing device includes a crank member 1, a frame one 2-1, a frame two 2-2, a frame three 2-3, a frame four 2-4, and a frame five 2 -5, rack six 2-6, driving dial 3, connecting rod member 5, reciprocating member 6, ultrasonic transducer 7, cutting knife cover 8, ultrasonic cutting knife 9, transport plate one 11-1, transport plate two 11-2, transport plate three 11-3, transport driven wheel 12-1, transport driving wheel 12-2, conveyor belt 13, driving pin 14, driven sheave 15, driving shaft 16 and driven shaft 17. Wherein, frame one 2-1, frame two 2-2, frame three 2-3, frame four 2-4, frame five 2-5 and frame six 2-6 are used for fixing different components; Member 1 and driving dial 3 are fixed on the driving shaft 16, see attached figure 2 ;Under the action of the driving mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com