Mechanical shock-absorbing type suspension travel automatic regulator

An automatic adjustment and automatic adjustment technology, applied in the direction of suspension, elastic suspension, seat suspension, etc., can solve the problems of poor applicability, complex hydraulic structure, inconvenient maintenance, etc., and achieve the effect of easy promotion and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

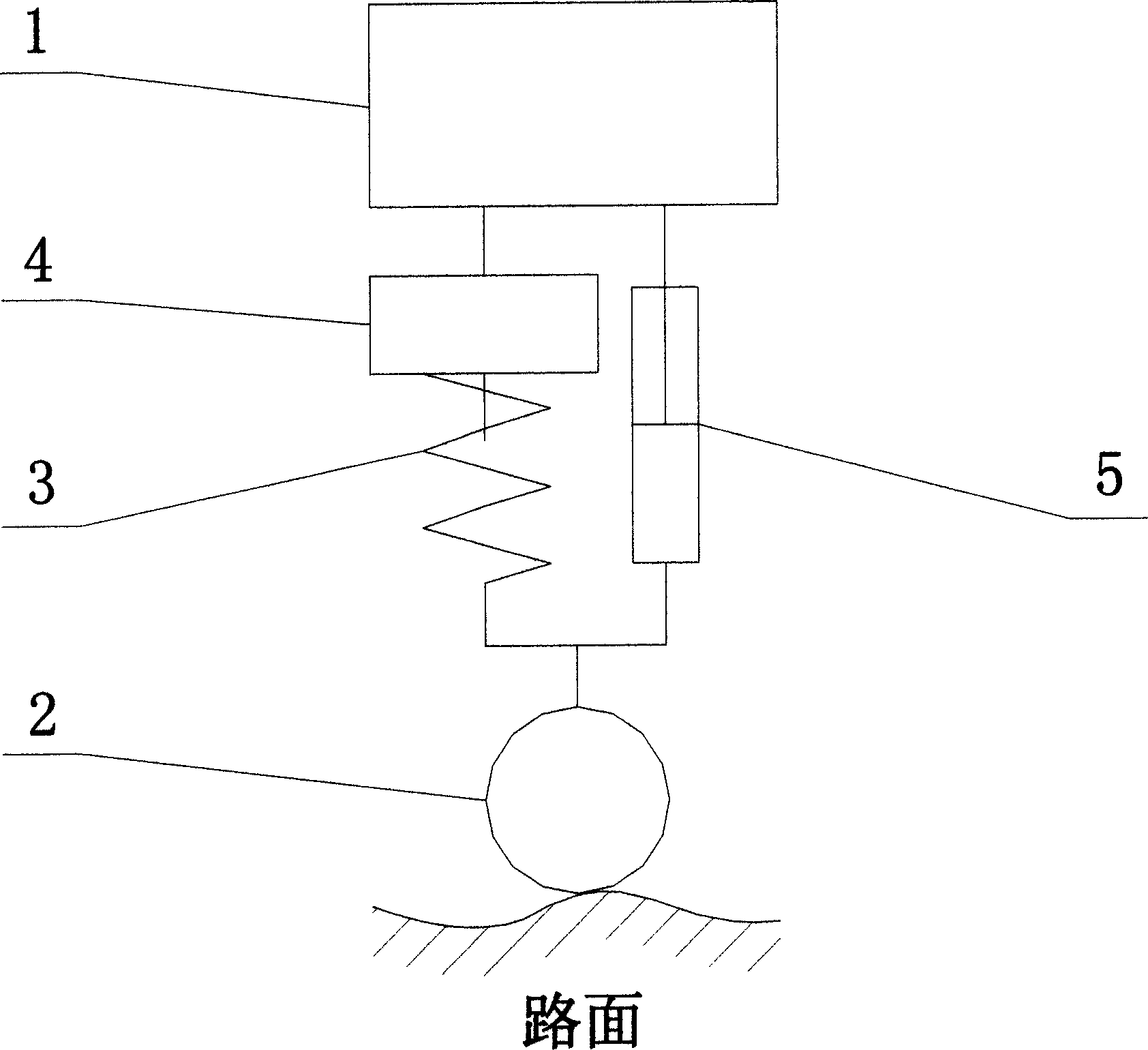

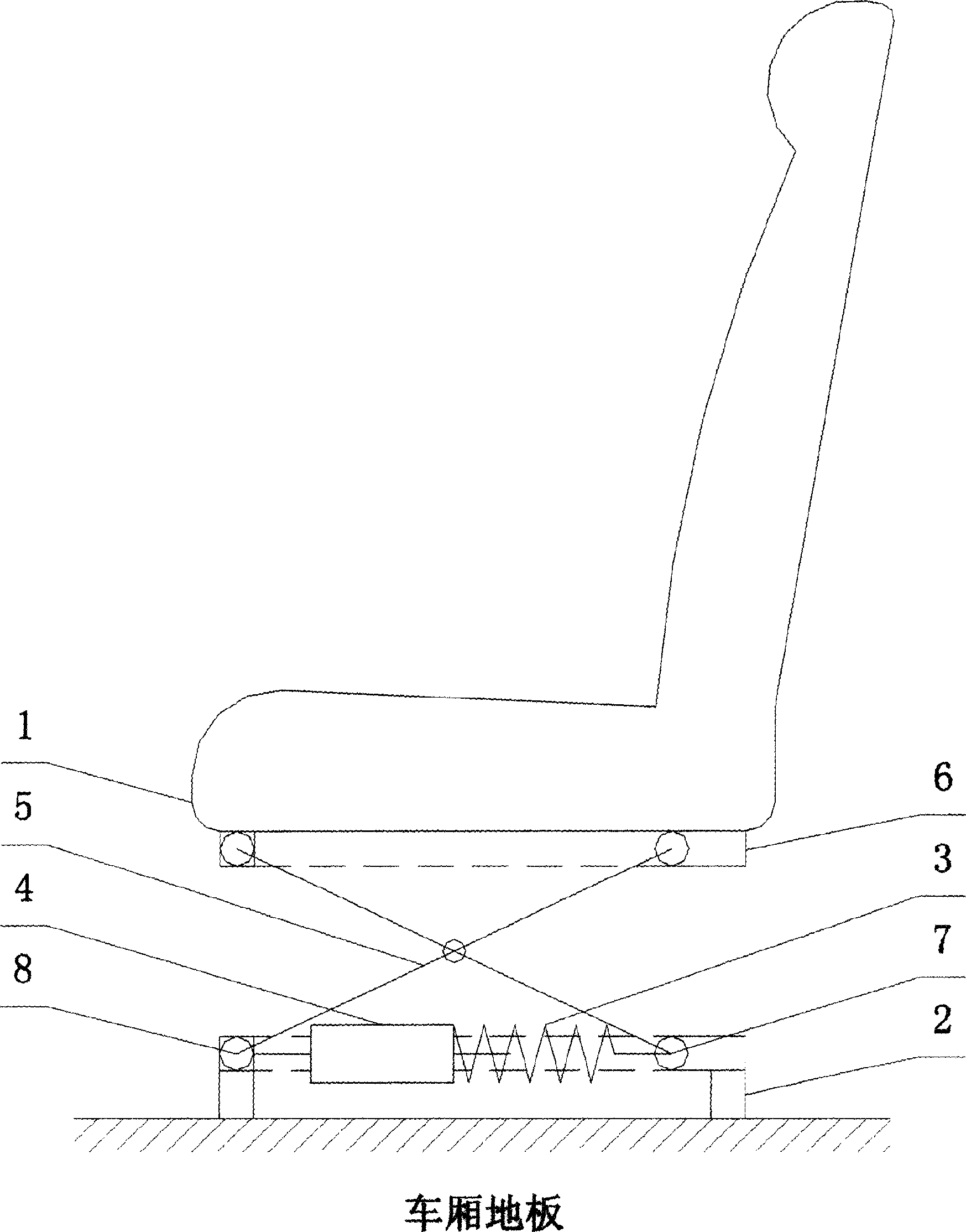

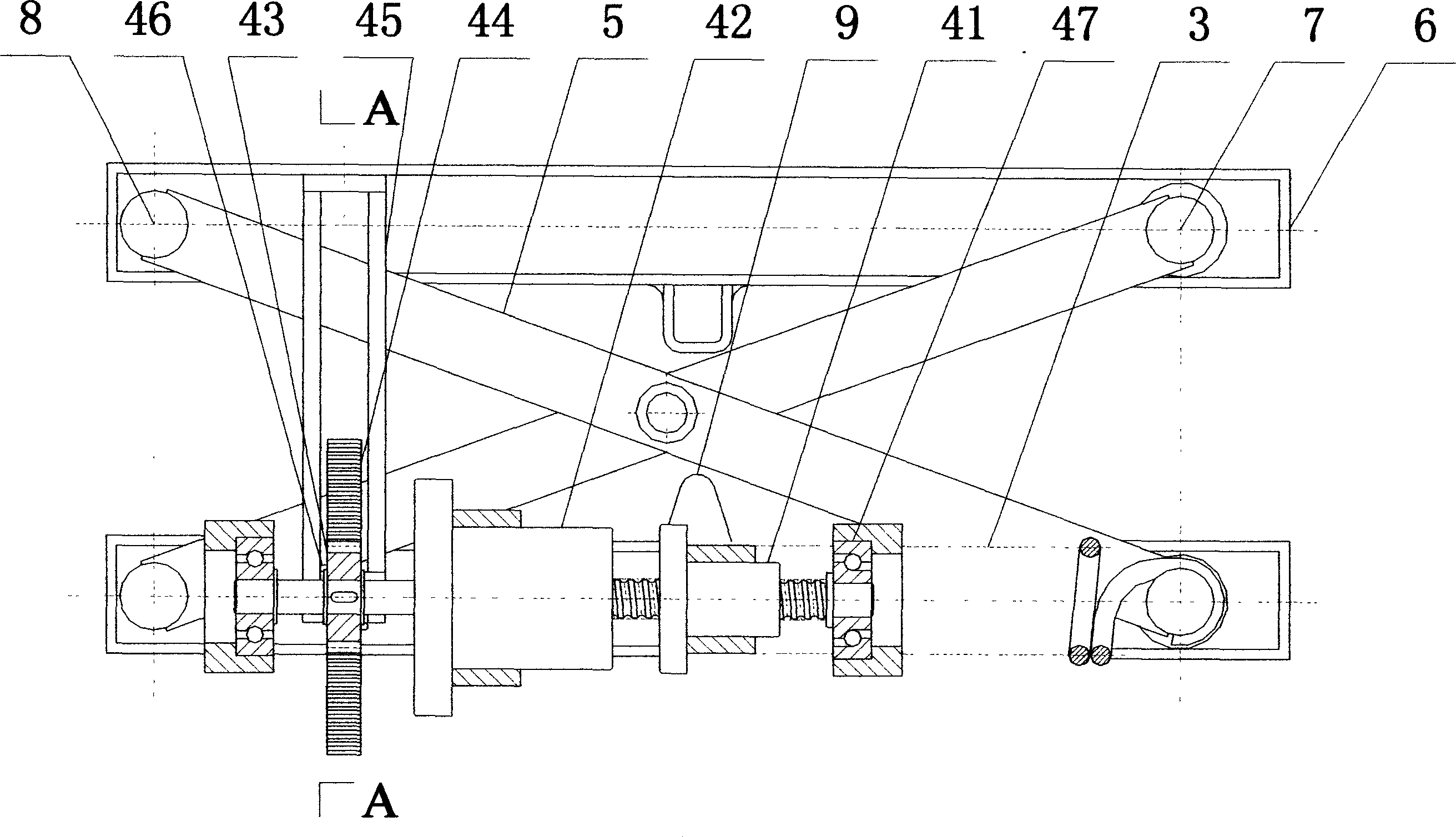

[0014] 1. in figure 1 In the shown embodiment, the suspension stroke of the present invention automatically adjusts the formula 1 / 4 vehicle model mainly by: vehicle body (1), wheel (2), compression spring (3), automatic centering device (4), damper ( 5) and other parts, wherein: the compression spring and the automatic centering device are connected in parallel with the damper and installed between the vehicle body and the wheel. Its working principle is: using the up and down motion of the vehicle suspension, through the reciprocating motion mechanism, intermittent motion mechanism, anti-reversal mechanism and rolling screw transmission mechanism of the automatic centering device, the upper connection end of the compression spring is driven relative to the stroke according to the static load. Points do reciprocating intermittent motions up and down with unequal ampli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com