Device for preparing dissolution media

A dissolution medium and main control device technology, applied in the general layout of liquid degassing, chemical instruments and methods, liquid degassing, etc., can solve the problems of limiting drug dissolution, affecting drug credibility, and deviation of experimental results, etc., to achieve High degree of automation and preparation efficiency, avoid medium concentration loss, ideal degassing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described below in conjunction with specific embodiment:

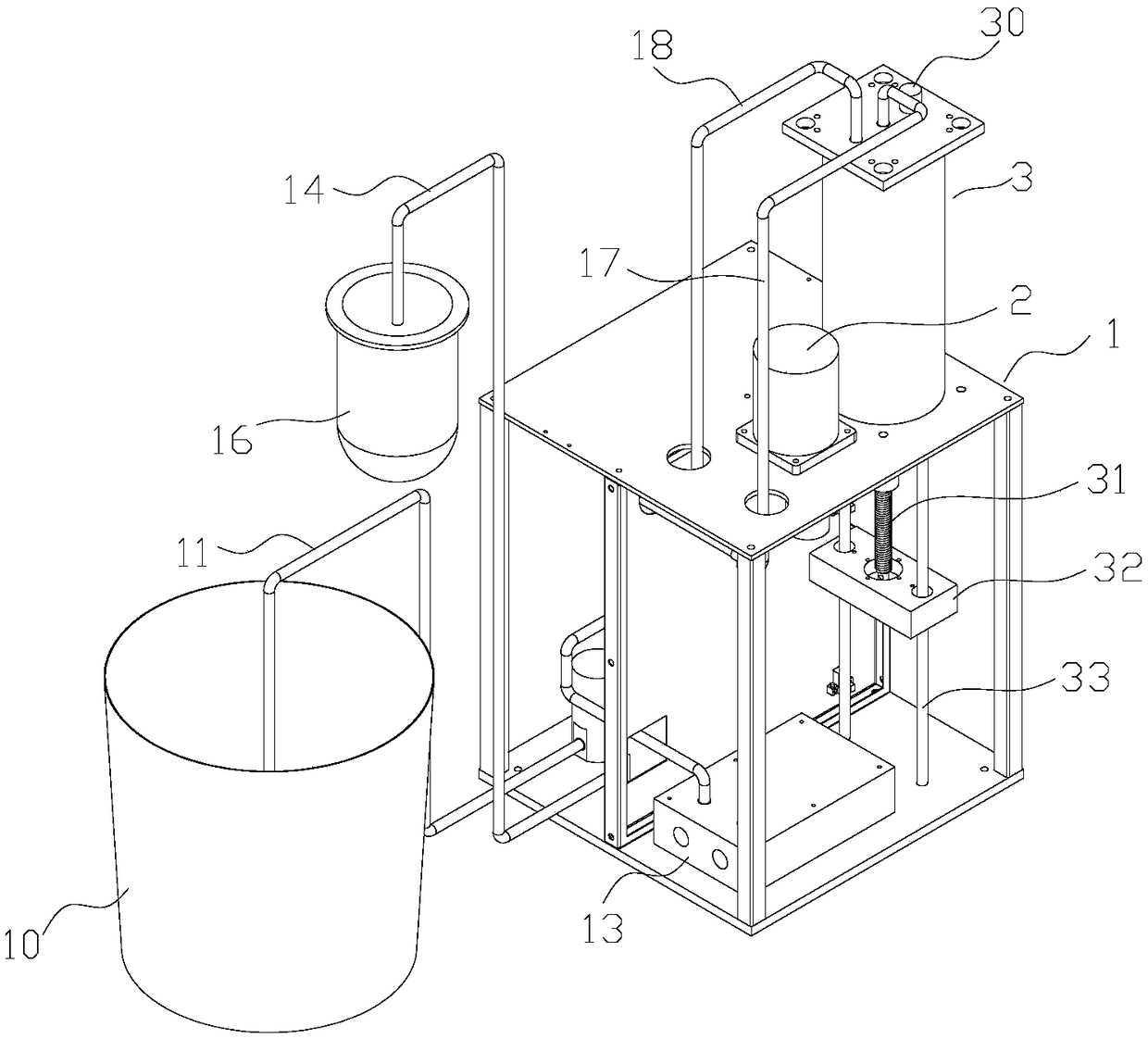

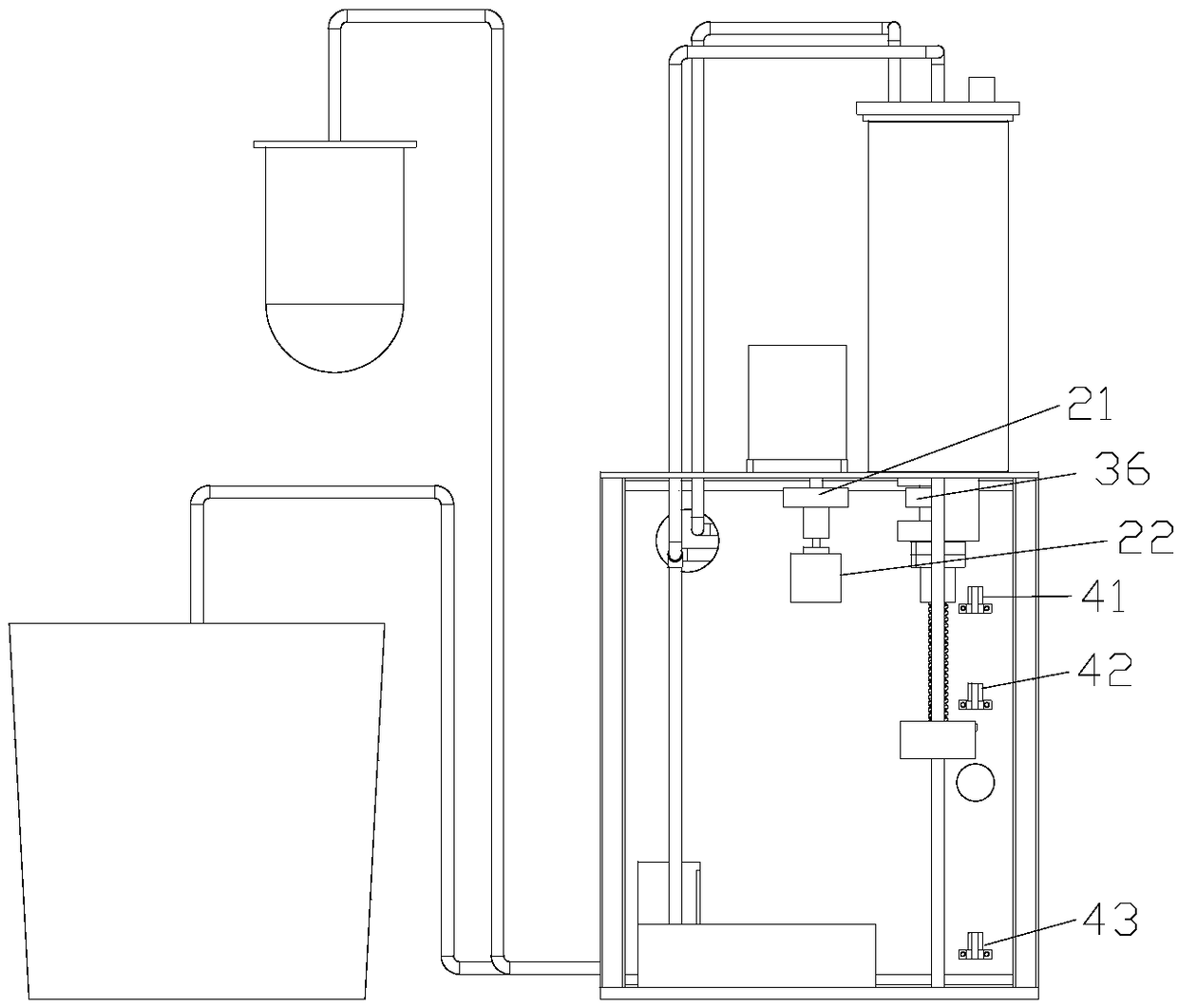

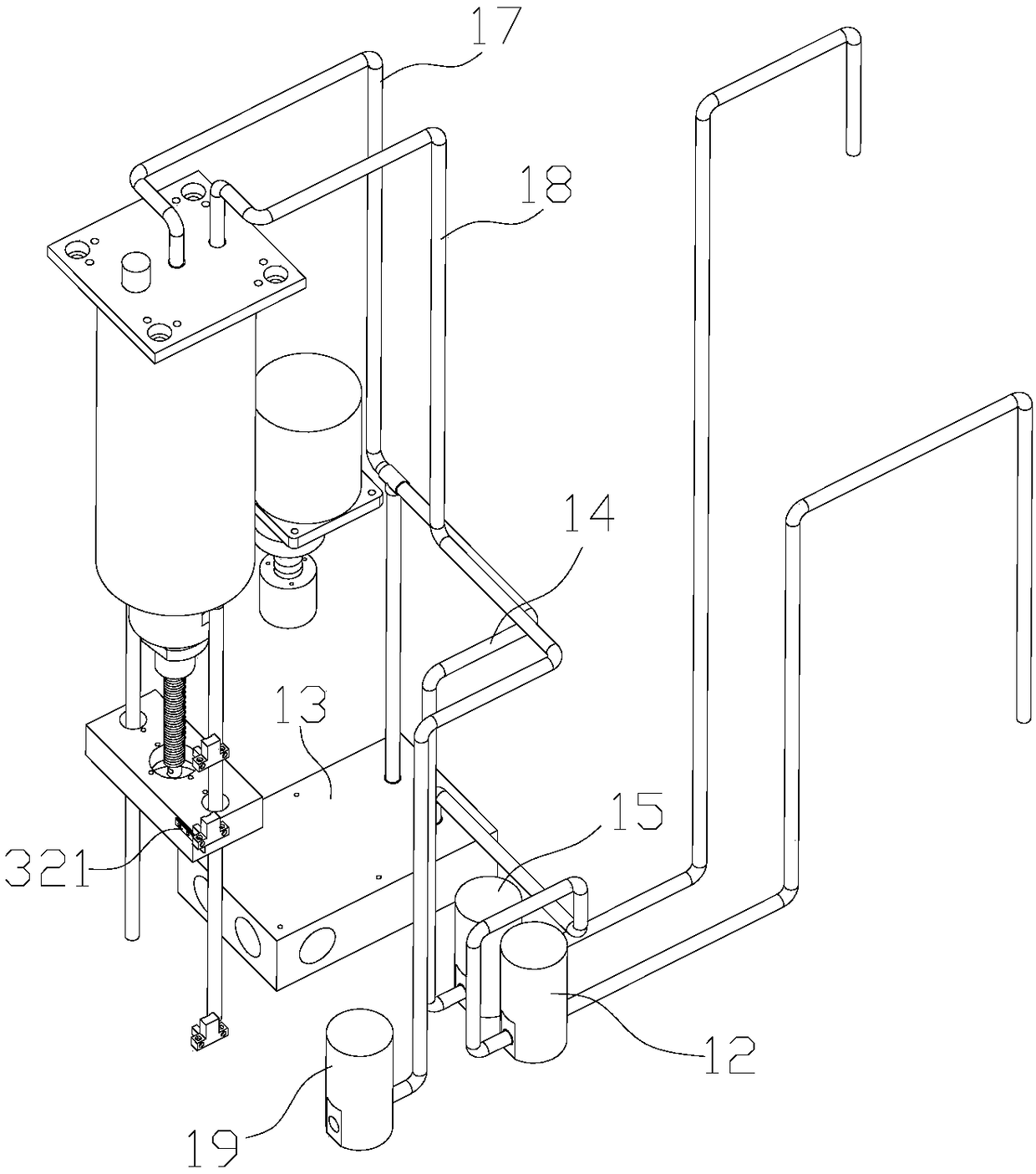

[0022] As an example, this embodiment is used to prepare a device for dissolution medium, such as Figures 1 to 4 As shown, it includes a main control device and a frame 1, and the frame 1 is provided with an input pipeline, an output pipeline, a vacuum mechanism, a heating water tank 13 and a heating rod.

[0023] Specifically, the frame 1 includes a top plate, a vertical plate and a bottom plate, the three are arranged in an I-shape, and are reinforced by setting columns at the four corners.

[0024] Input pipeline comprises input pipeline 11, and output pipeline comprises output pipeline 14, and input pipeline 11 is provided with electromagnetic valve 15, heating water tank 13, and output pipeline 14 is provided with electromagnetic valve 12, and input pipeline 11, output pipeline 14 and common pipeline 17 are connected by a tee, and the public pipeline 17 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com