Gas collecting and dust settling coal loosening device

A technology of coal evacuation and dust reduction, which is applied in coking ovens, petroleum industry, and separation of dispersed particles. It can solve problems such as overcapacity, high raw material lump coal prices, and low operating profits of semi-coke enterprises, so as to reduce extrusion and avoid deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

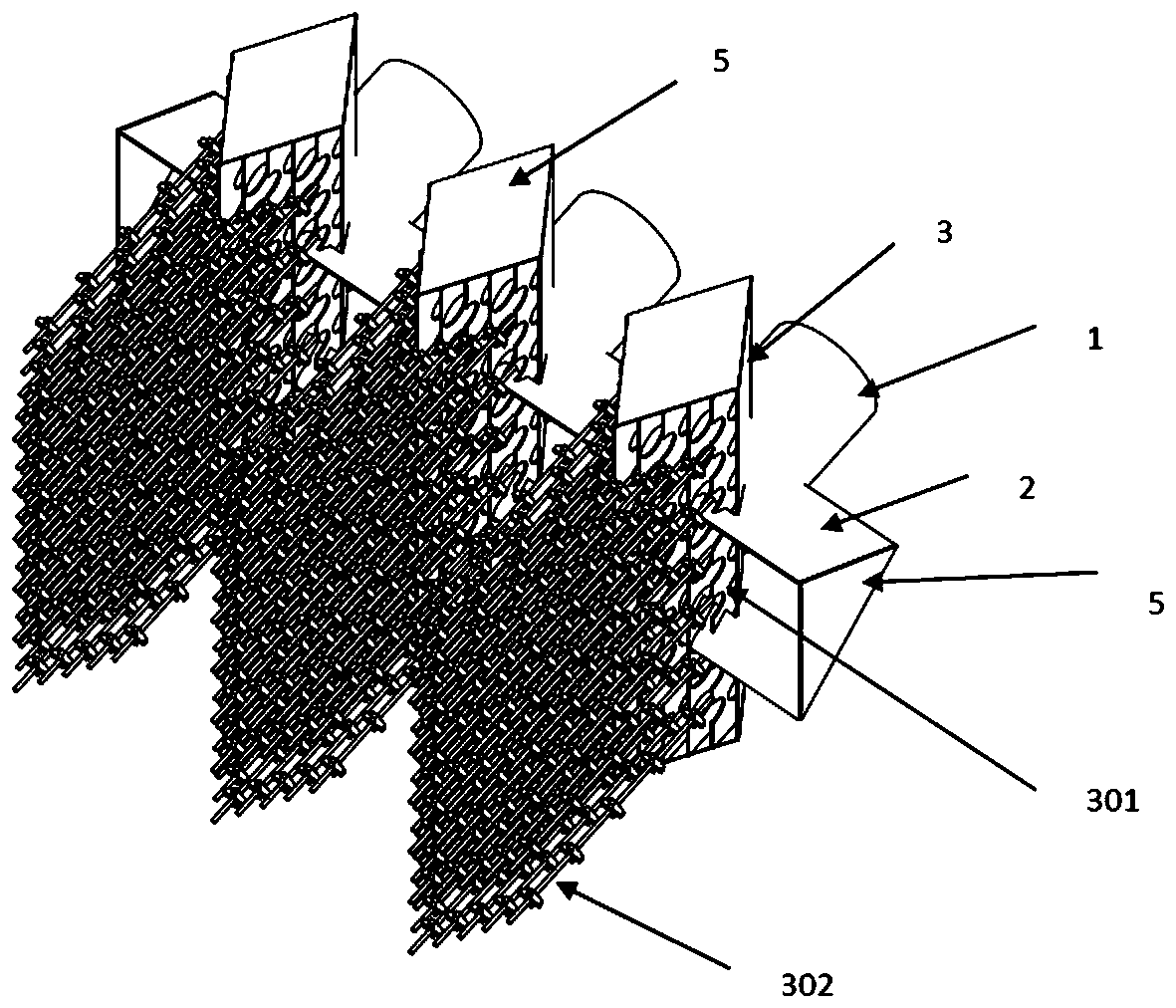

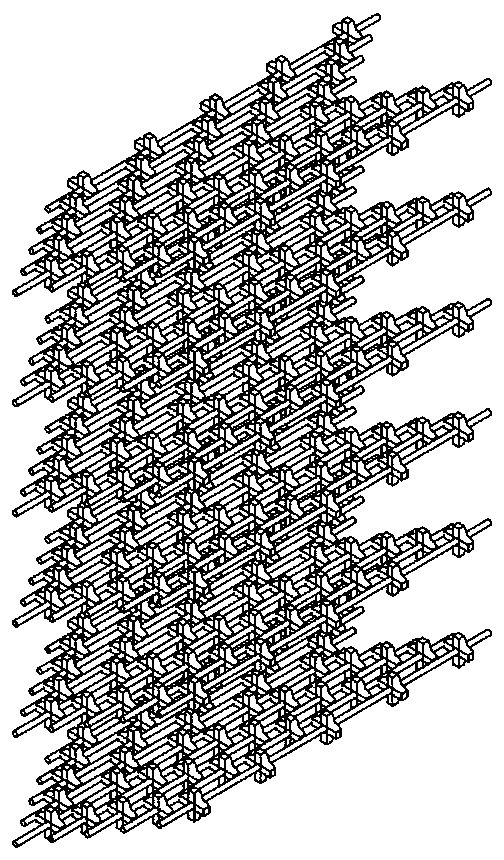

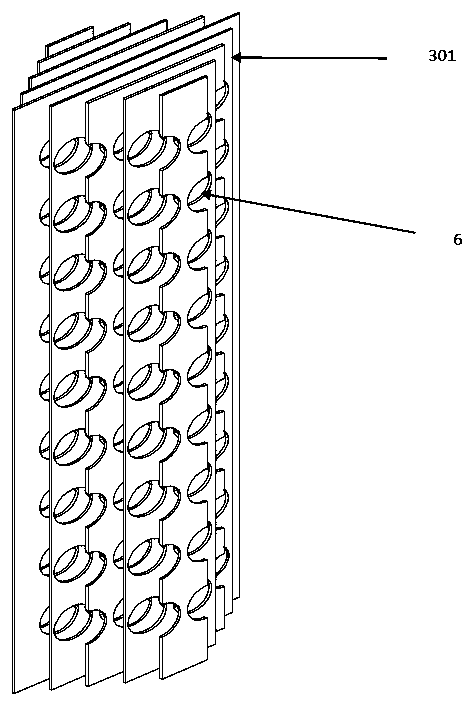

[0028] A gas-collecting, dust-reducing and coal-sparing device, comprising an air guide pipe 1 and an air guide channel communicated with the air guide pipe 1, the air guide channel includes a horizontally arranged main channel 2 and a main channel 2 perpendicular to the main channel 2 and inlaid side by side on the main channel 2 A plurality of secondary passages 3, the main passage 2 is provided with an air guide pipe 1 communicating with it, and both ends of the main passage 2 and the auxiliary passage 3 are provided with port sealing plates 5; the main passage 2 and the auxiliary passage 3 are provided with powerful Plate 4; several dedusting plates 301 are arranged in parallel in the secondary channel 3, the dedusting plates 301 are arranged along the length direction of the secondary channel 3, the dedusting plates 301 are provided with holes 6, and the dedusting plates 301 The lower edge is provided with a fixed rod 302, and the fixed rod 302 is provided with a coal scav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com