Runner device and mold filling method of centrifugal casting thin-wall cartridge receiver casting

A technology of centrifugal casting and casting, which is applied in the field of investment casting, can solve problems affecting the delivery quality of castings, achieve the effects of avoiding repair welding and repair procedures, shortening the production period, and improving the economic benefits of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the required protection scope is not limited to the description;

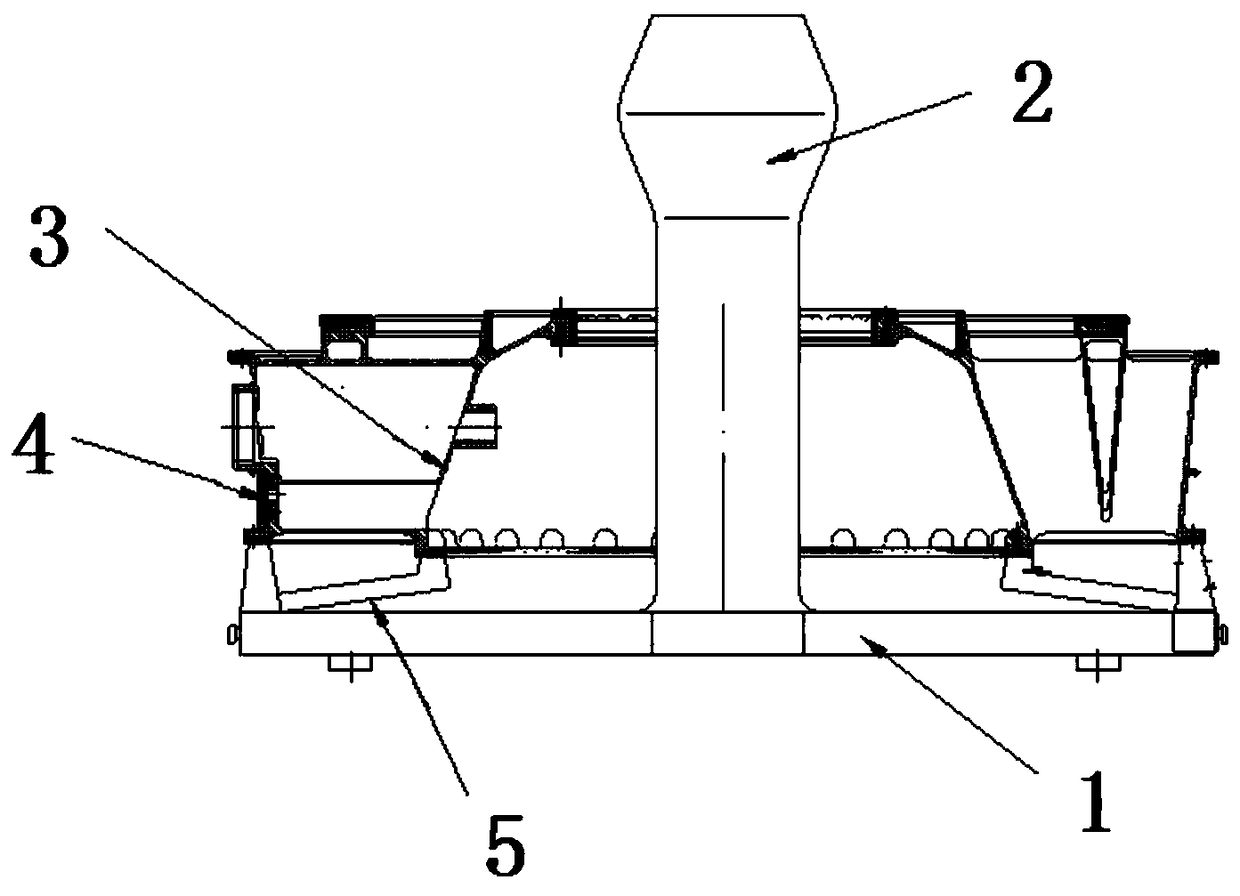

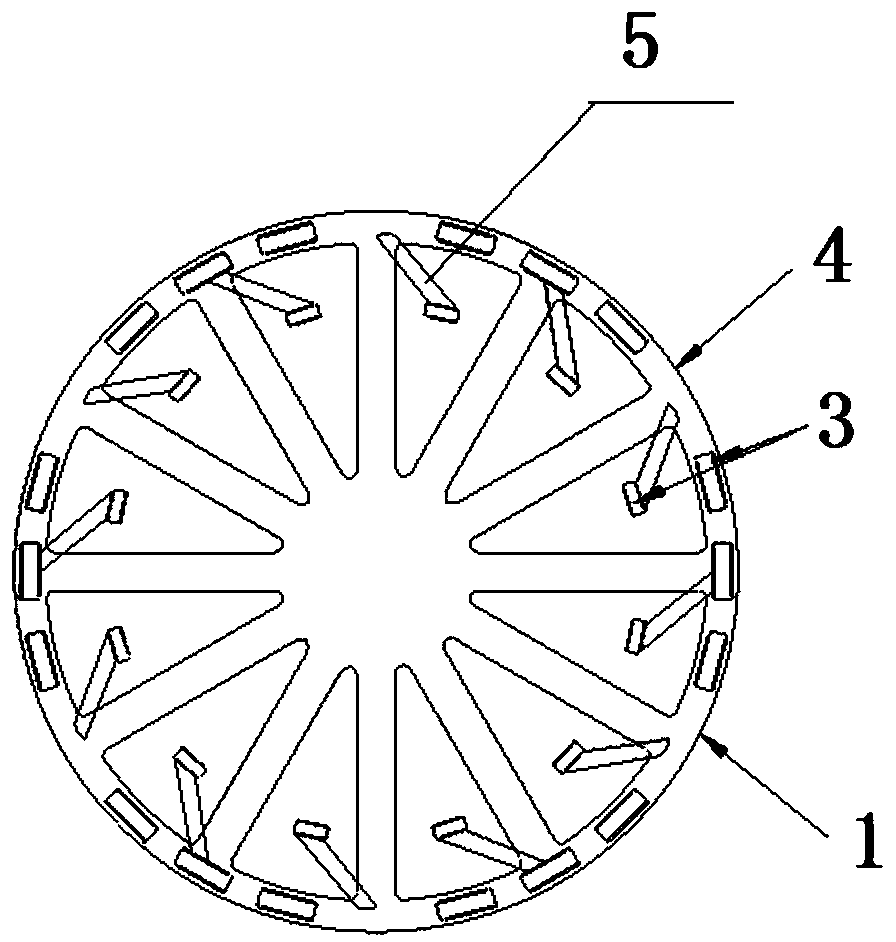

[0019] The invention provides a sprue device for centrifugal casting of thin-wall casing castings and a filling method thereof, such as figure 1 , figure 2 As shown, it includes a disc-shaped runner 1, a sprue 2 is vertically bonded on the runner 1, and a circular inner runner 3 and a circular outer runner are bonded on the runner 1. The runner 4 , the inner runner 3 and the outer runner 4 are all around the area outside the sprue 2 , and the inner runner 3 and the outer runner 4 are connected by several overlapping runners 5 .

[0020] Adopting the technical scheme of the present invention, when pouring the molten metal, the molten metal is firstly filled into the joint between the sprue and the runner through the sprue. Narrowing, the pressure head of this part of the molt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com