Residual stress detection auxiliary device facing non-ferromagnetic part

A residual stress and auxiliary device technology, applied in measuring devices, positioning devices, metal processing machinery parts, etc., can solve the problem that ferromagnetic parts cannot be fixed, and achieve the effect of increasing versatility, easy operation and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

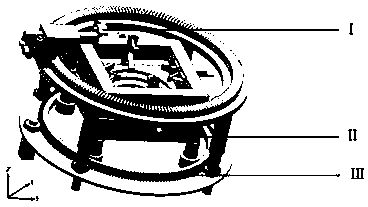

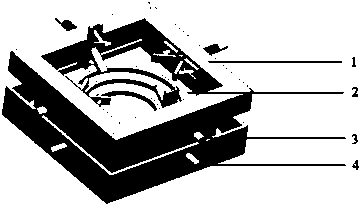

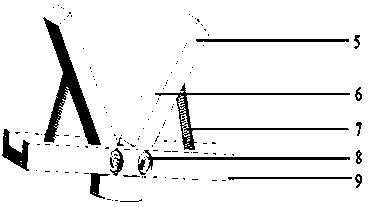

[0023] Such as figure 1 , a structural schematic diagram of an auxiliary device for clamping non-ferromagnetic parts and multi-angle drilling for blind hole method stress detection equipment of the present invention. The feature of the present invention is: comprise the clamping part of non-ferromagnetic parts, its structure is as figure 2 shown; including the multi-angle punching part of non-ferromagnetic parts, its structure is as follows image 3 As shown; the multi-angle punching part includes a coarse adjustment part and a fine adjustment part, and the structure is as follows Figure 4 with Figure 5 shown.

[0024] Such as figure 2 , put the non-ferromagnetic parts between the clamping plates, according to the size of the parts in the Z direction, the movement of the four clamping plates in the Z direction can be adjusted separately by rotating the driving handle to adapt to the clamped parts in the Z direction size. According to the shape characteristics of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com