Manufacturing method of multifunctional universal belt

A production method and multi-functional technology, applied in clothing belts, clothing, clothing, etc., can solve the problems of moldy bacteria, poor tensile performance, scratch resistance, etc., and achieve the effect of natural and beautiful edges and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

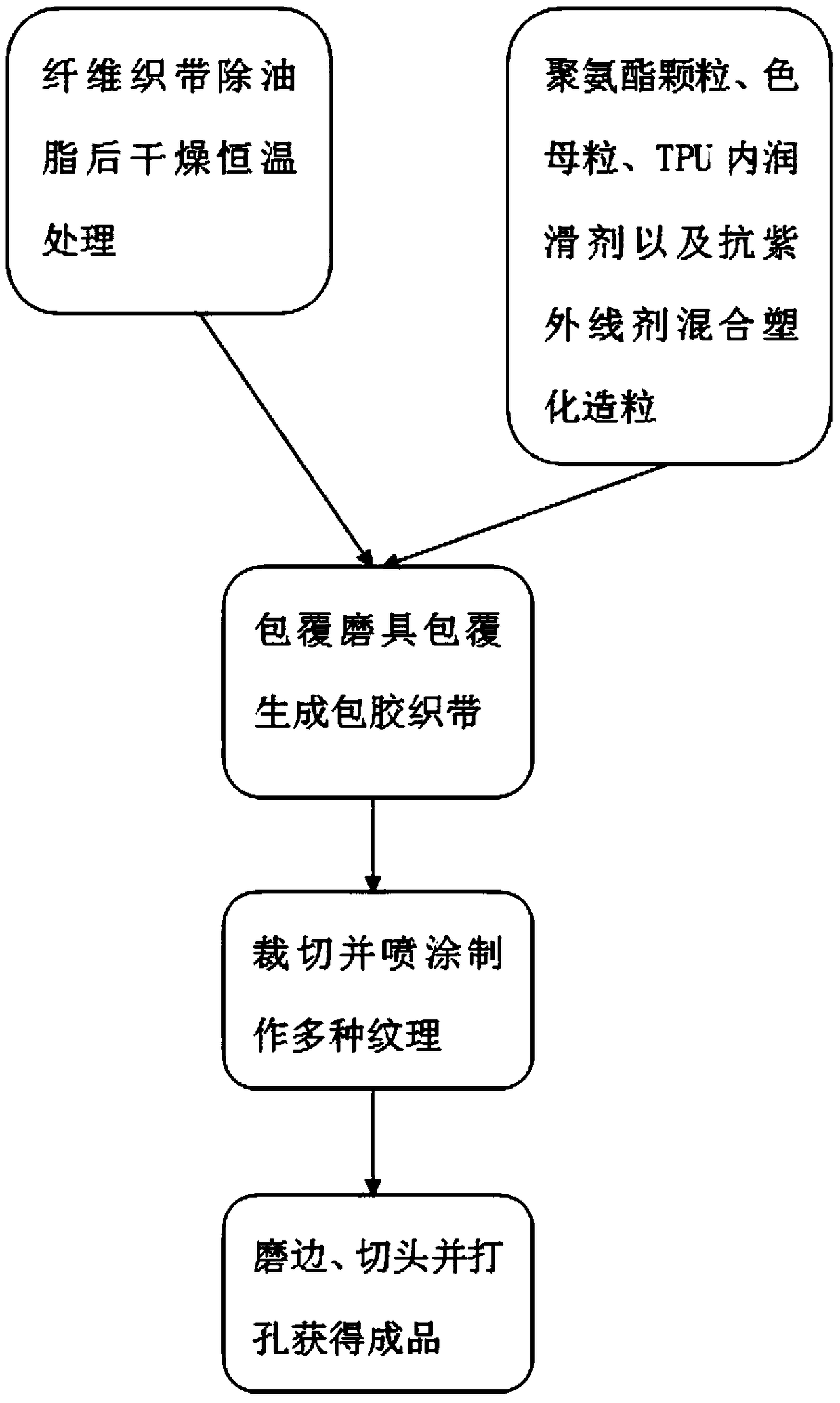

[0030] Such as figure 1 As shown, the multifunctional and all-round belt manufacturing method provided by the present embodiment:

[0031] A method for manufacturing a multifunctional all-round belt, the method comprising the following steps:

[0032] (1) Structure setting: including the base material, the base material is a fiber webbing, the base material is covered with polymer materials in one piece, and the surface layer of the base material is shaped with different patterns and colors;

[0033] (2) Preparation steps:

[0034] (2-1) Set the fiber webbing, and remove the surface grease, set the polyurethane particles with a Shore hardness between 75-85, set the color masterbatch, TPU internal lubricant and anti-ultraviolet agent; the fiber webbing is heated To 150°C-200°C close to the plasticizing temperature.

[0035] (2-2) The fiber ribbon becomes dry and constant temperature state after dehydration and heating treatment, and the polyurethane particles are mixed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com