Automatic bag-making system for plastic three-dimensional bag with square bottom bag clamping patch

A three-dimensional bag, automatic manufacturing technology, applied in bag making, container manufacturing machinery, flexible container manufacturing, etc., can solve the problem of low work efficiency, high labor cost, affecting the molding firmness and production efficiency issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

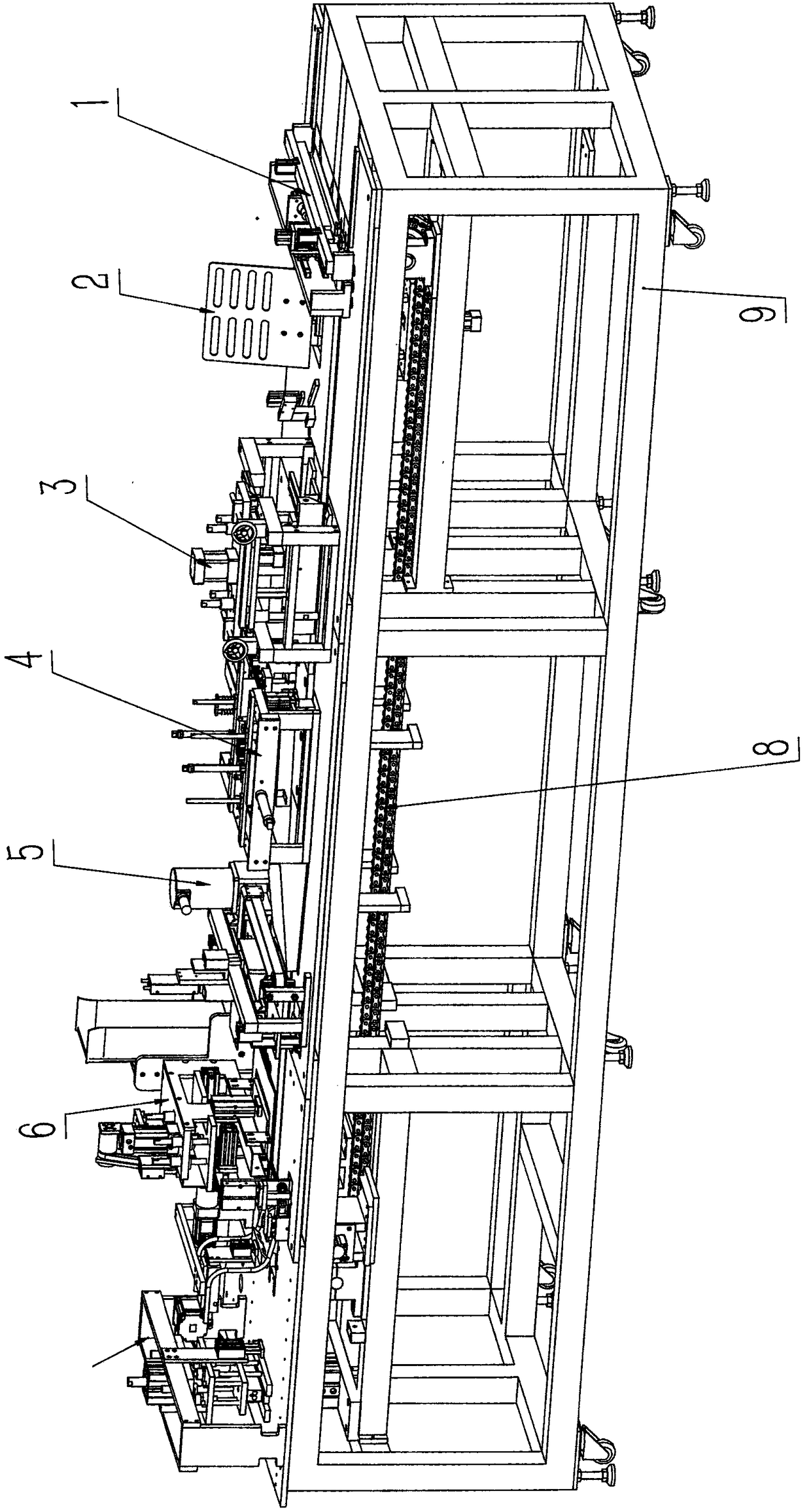

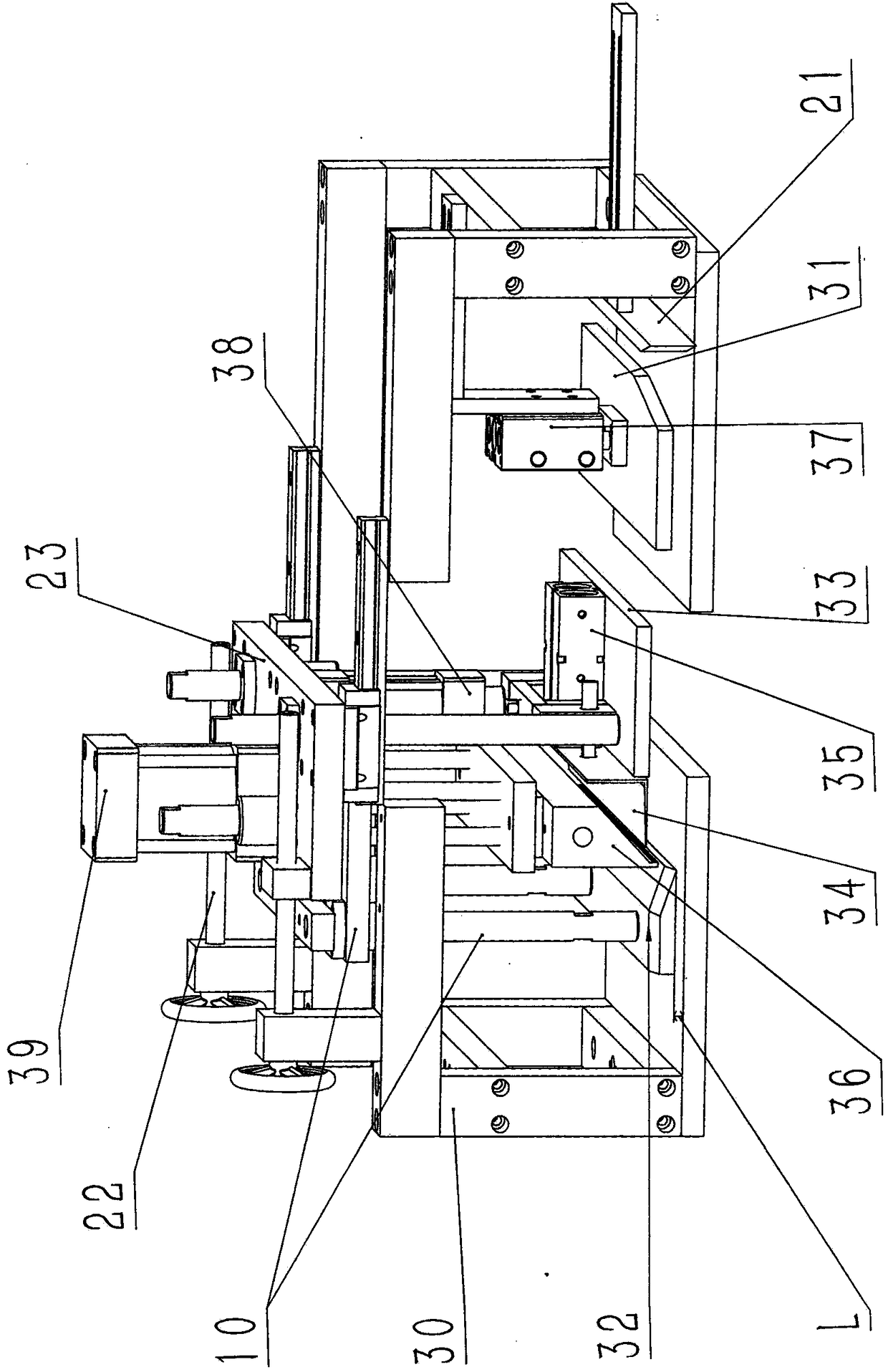

[0024] refer to figure 1 It can be seen that the automatic bag-making system of the plastic three-dimensional bag with the patch entrained at the bottom of the side of the present invention includes a main frame 9, and a sheet material positioning feeding device 1 and a double-folding device 2 are sequentially installed on the front portion of the general frame 9, On the main frame 9, and at the side of the double-folding device 2, a single-side ironing device 3, a double-side folding device 4, and a bottom opening device 5 are successively installed, and on the main frame 9 On, and in the middle of the sheet material positioning and feeding device, the double-folding device, the single-side edge ironing device, the two-side edge folding device, and the bottom opening device, a manipulator sheet material transmission device 8 (wraparound rotation) is installed; Bottom patch folding device 6 and bottom ironing device 7 are sequentially installed on the main frame 9 and at the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com