Intelligent cart for allowing junk car to move on dismantling production line through fixing

An automatic assembly line and smart car technology, which is applied to the removal of solid waste, motor vehicles, transportation and packaging, etc., to achieve the effect of reducing labor complexity, improving recycling efficiency, and compact site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

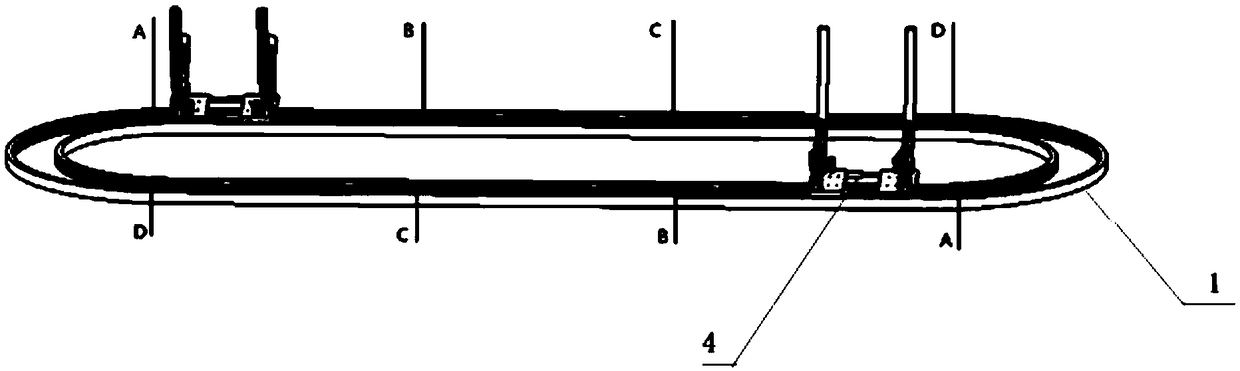

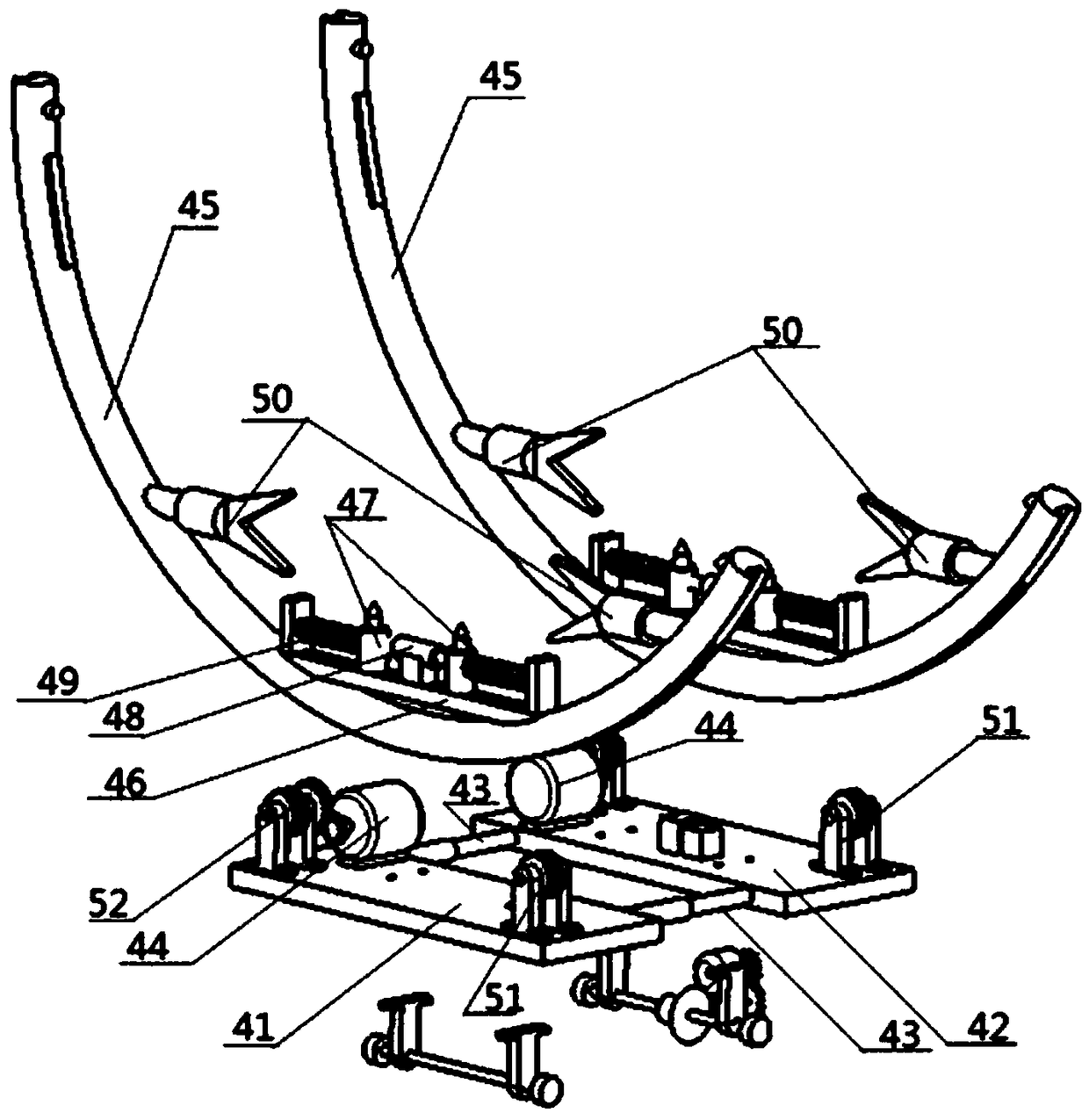

[0052] An intelligent trolley 4 that fixes waste cars moving on an automatic assembly line for dismantling is fixed on a circular track 1 through a driving and transmission mechanism, and accurately controls the movement and adjustment of on-site equipment through an intelligent vision control system.

[0053] The circular track is provided with inner and outer tracks, which are arranged in an elliptical shape. The circular track is integrated with the fixed bracket, and is firmly fixed on the workshop floor by expansion bolts.

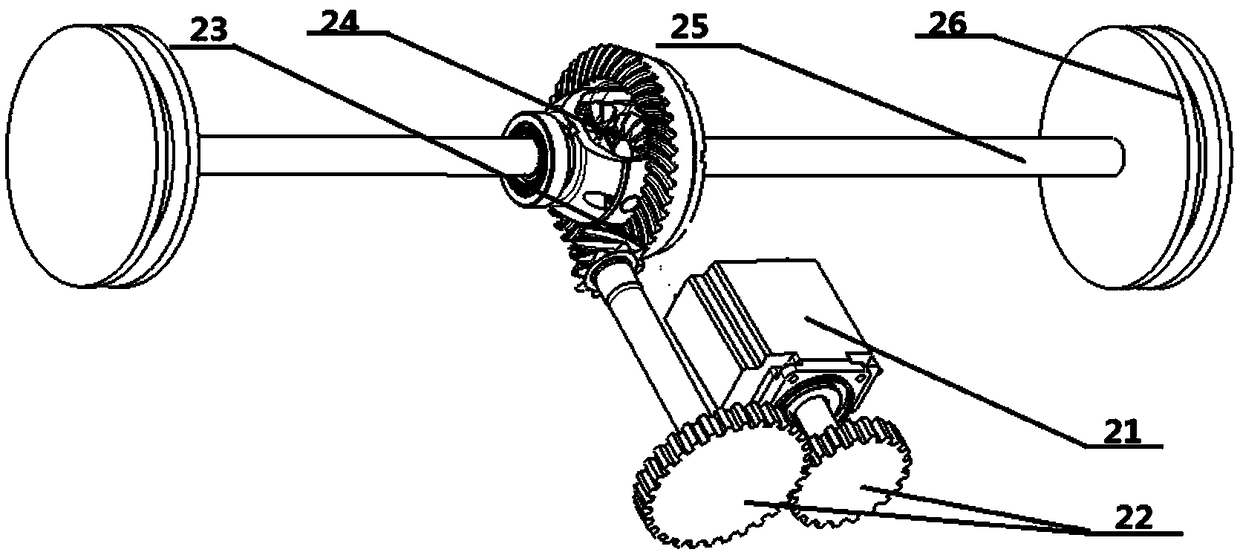

[0054] The driving and transmission mechanism is fixed on the bottom of the rear plate 42 of the smart car 4, and is made up of a motor 21, a reduction differential mechanism, a half shaft 25 and a drive wheel 26.

[0055] The driving and transmission mechanism is composed of a motor 21, a deceleration differential mechanism, a half shaft 25 and a drive wheel 26; the power of the motor 21 is decelerated by the first-stage deceleration mechanism 22, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com