Wheel sleeve part feeding device

A technology of parts and disc sleeves, which is applied in the field of machining and feeding devices, can solve the problems of difficulty in improving efficiency and long fixture replacement time, and achieve the effect of simple structure, solving the problem of fixture replacement, and improving feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

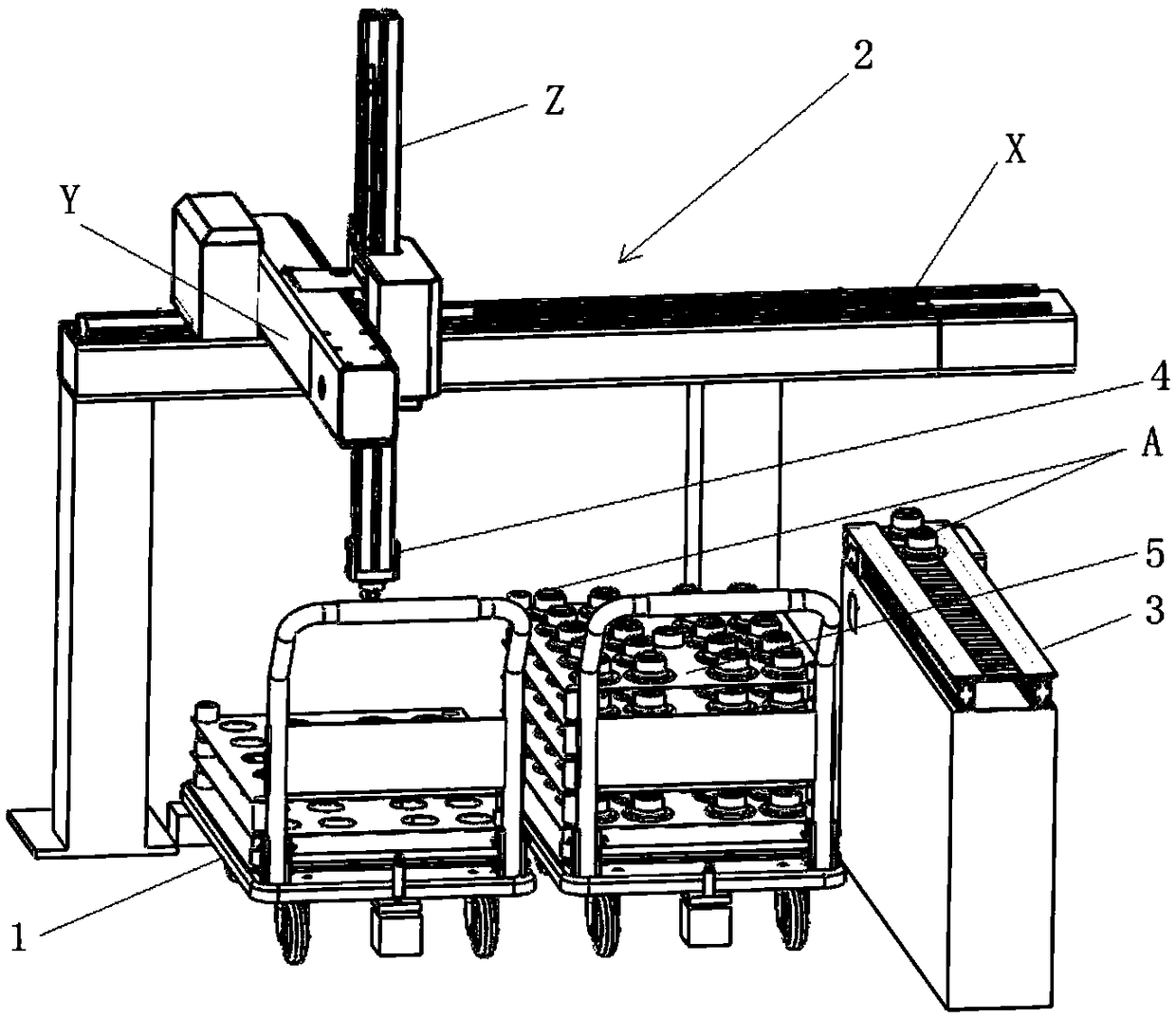

[0027] See figure 1 , the feeding device for disc sleeve parts provided by the present invention comprises a three-axis truss robot 2, two trolleys 1 and their positioning devices, and several pallets 5; the three-axis truss robot 2 consists of Composed of XYZ linear module and pneumatic gripper 4, XYZ linear module includes horizontal axis X, vertical axis Y and vertical axis Z, pneumatic gripper 4 is installed at the lower end of vertical axis Z, and pneumatic gripper 4 is used for grasping part A Picking and releasing, the positioning device of the trolley 1 is set on the ground compatible with the three-axis truss robot 2, and is used to limit the trolley 1 to a designated position to ensure that the three-axis truss robot 2 can grab all parts and Placement tray 5, may also include conveyor belt 3 for transporting parts A.

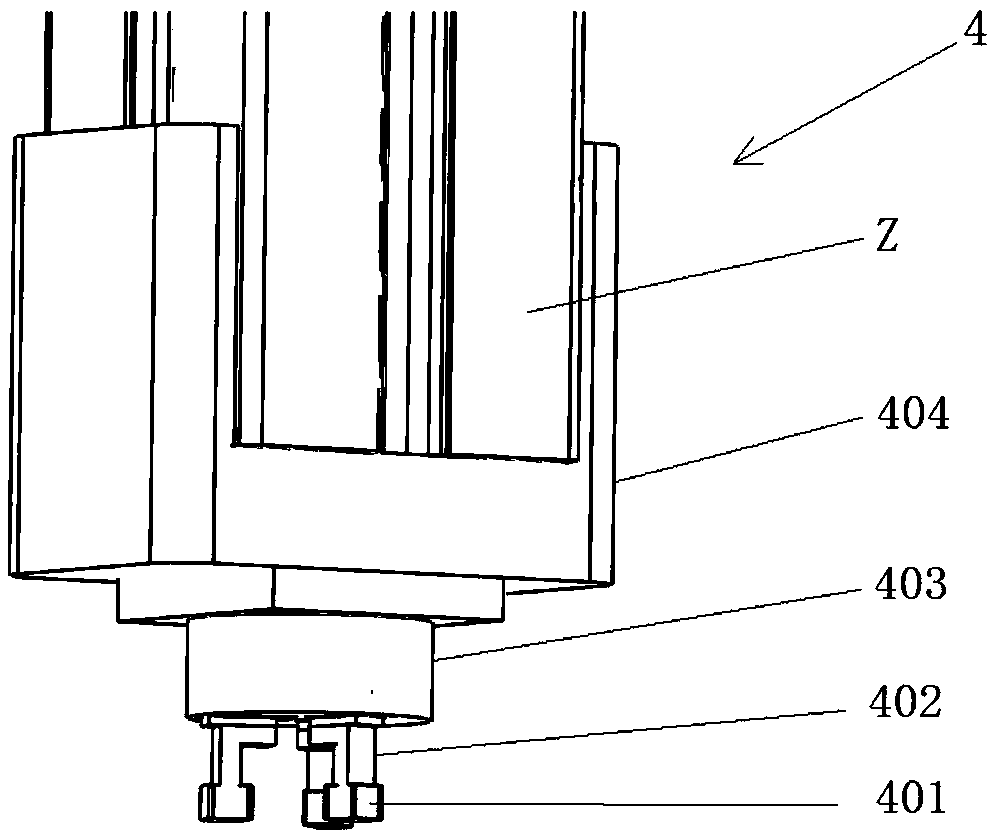

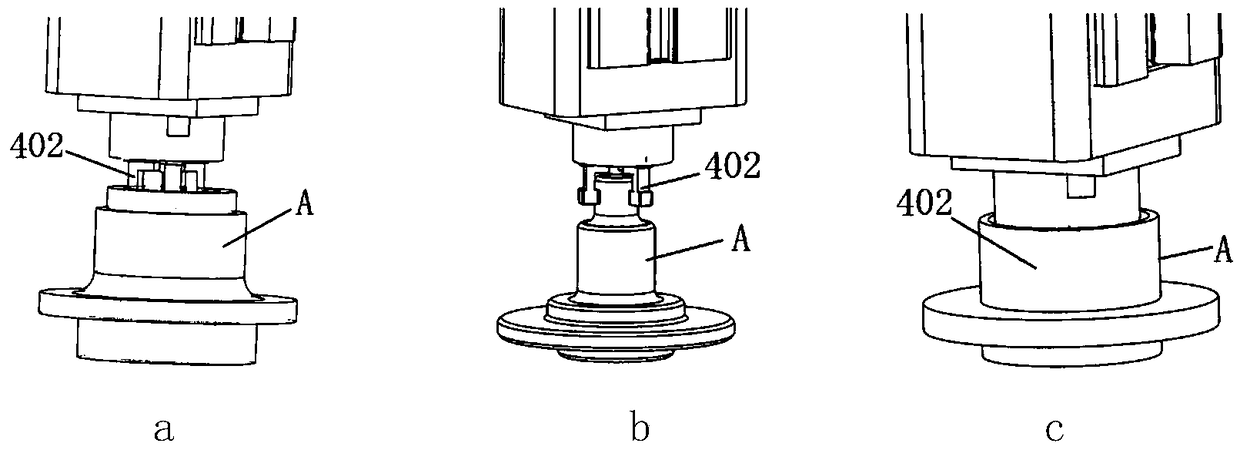

[0028] See figure 2 , the pneumatic gripper 4 consists of a cylinder base 404 installed on the vertical axis Z, a cylinder 403 located on the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com