A kind of transparent glitter polyurethane TPU chain tooth, preparation method and slide fastener

A polyurethane and chain element technology, applied in the direction of fasteners, sliding fastener elements, clothing, etc., can solve the problems of lack of, can not be widely used, colorful appearance characteristics, etc., to achieve the effect of excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

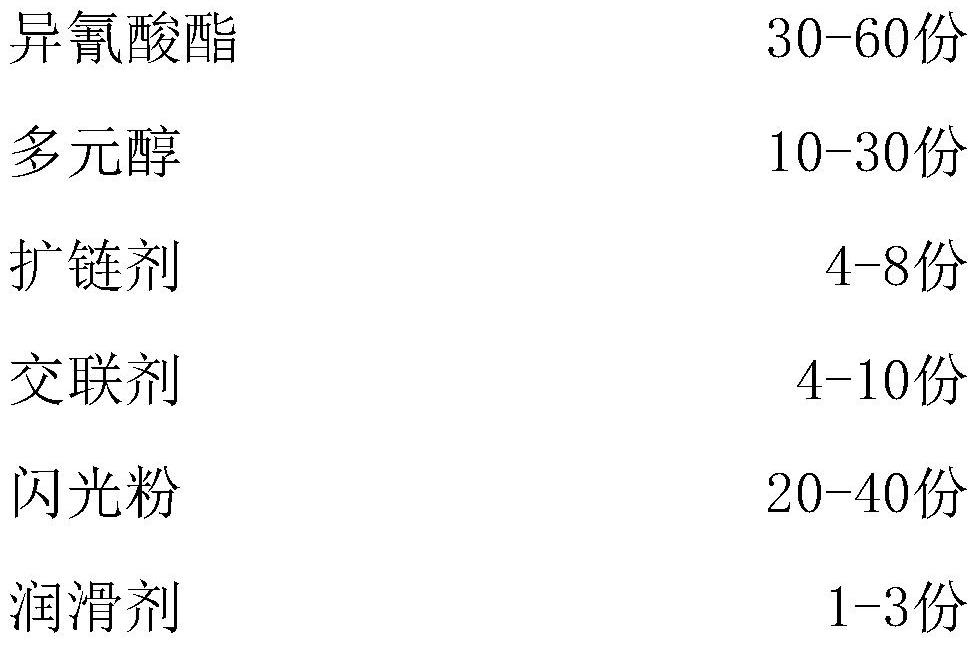

[0027] A transparent flashing polyurethane TPU chain tooth, made from the following raw materials in parts by weight:

[0028]

[0029] The glitter powder is composed of a micron prism pyramid monomer and a polyacrylamide layer covering the micron prism pyramid monomer.

[0030] Wherein, the isocyanate is 4,4'-diphenylmethane diisocyanate, and the -NCO content of the 4,4-diphenylmethane diisocyanate is 22%.

[0031] Wherein, the polyol is composed of ethylene oxide propylene oxide polyether polyol and polycaprolactone polyol in a ratio of 1:1 by weight, and the ethylene oxide propylene oxide polyether polyol The hydroxyl value is 50 mgKOH / g, and the hydroxyl value of the polycaprolactone polyol is 96 mgKOH / g.

[0032] Wherein, the chain extender is composed of hydroquinone dihydroxyethyl ether, trimethylolpropane and triethylene glycol in a weight ratio of 2:1:1.

[0033] Wherein, the preparation method of the crosslinking agent is: mix toluene diisocyanate and castor oil...

Embodiment 2

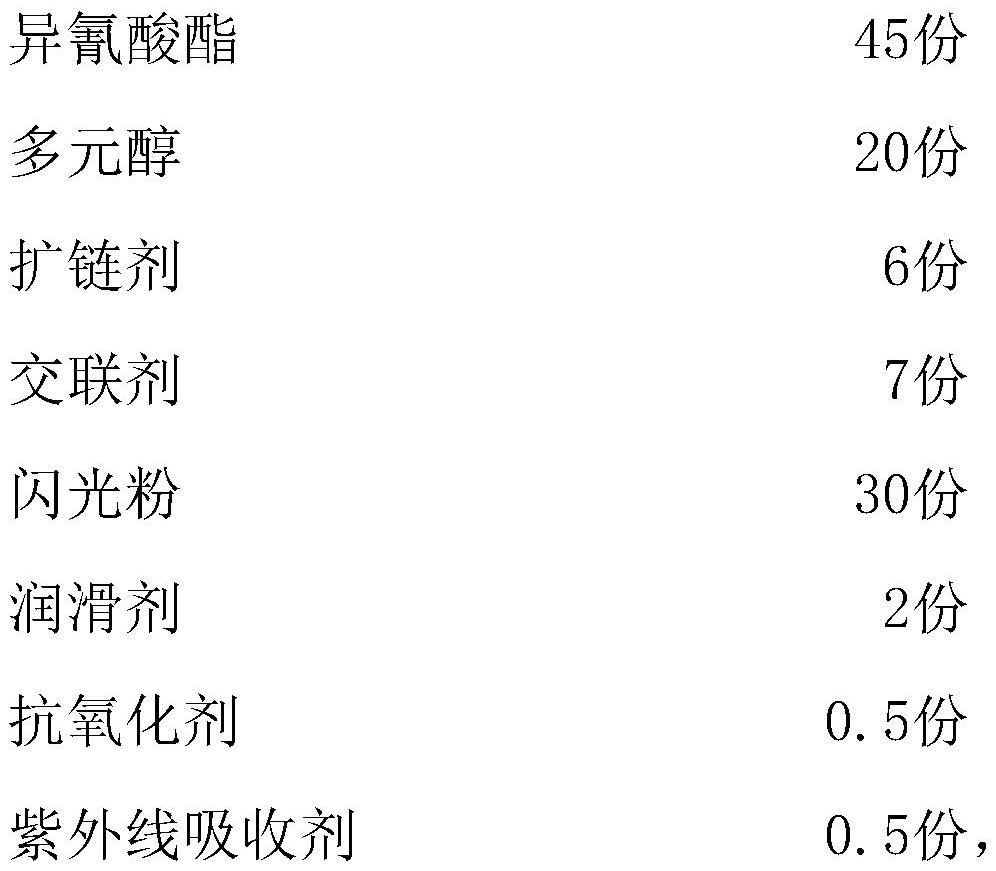

[0042] A transparent flashing polyurethane TPU chain tooth, made from the following raw materials in parts by weight:

[0043]

[0044] The glitter powder is composed of a micron prism pyramid monomer and a polyacrylamide layer covering the micron prism pyramid monomer.

[0045] Wherein, the isocyanate is 4,4'-diphenylmethane diisocyanate, and the -NCO content of the 4,4-diphenylmethane diisocyanate is 18%.

[0046] Wherein, the polyol is composed of ethylene oxide propylene oxide polyether polyol and polycaprolactone polyol in a ratio of 1-3:1-3 by weight, and the ethylene oxide propylene oxide polyol The hydroxyl value of the ether polyol is 40 mgKOH / g, and the hydroxyl value of the polycaprolactone polyol is 90 mgKOH / g.

[0047] Wherein, the chain extender is composed of hydroquinone dihydroxyethyl ether, trimethylolpropane and triethylene glycol in a weight ratio of 3:1:1.

[0048] Wherein, the preparation method of the cross-linking agent is as follows: mix toluene d...

Embodiment 3

[0057] A transparent flashing polyurethane TPU chain tooth, made from the following raw materials in parts by weight:

[0058]

[0059] The glitter powder is composed of a micron prism pyramid monomer and a polyacrylamide layer covering the micron prism pyramid monomer.

[0060] Wherein, the isocyanate is 4,4'-diphenylmethane diisocyanate, and the -NCO content of the 4,4-diphenylmethane diisocyanate is 26%.

[0061] Wherein, the polyol is composed of ethylene oxide propylene oxide polyether polyol and polycaprolactone polyol in a ratio of 3:1 by weight, the ethylene oxide propylene oxide polyether polyol The hydroxyl value is 60 mgKOH / g, and the hydroxyl value of the polycaprolactone polyol is 102 mgKOH / g.

[0062] Wherein, the chain extender is composed of hydroquinone dihydroxyethyl ether, trimethylolpropane and triethylene glycol in a weight ratio of 4:2:1.

[0063] Wherein, the preparation method of the cross-linking agent is: mix toluene diisocyanate and castor oil, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com