A low-pressure carbonate reservoir gas well temporary plugging workover fluid and its preparation and application method

A carbonate reservoir and workover fluid technology, which is applied in wellbore/well components, chemical instruments and methods, earthwork drilling and production, etc., can solve the problem of long contact time between formation and fluid, severe water lock damage, and inability to Realize problems such as temporary plugging and workover, achieve good anti-swelling effect, reduce damage, and reduce water lock damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

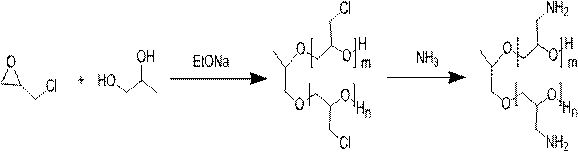

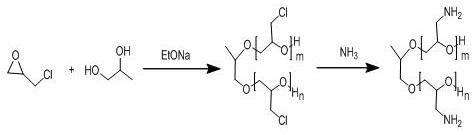

Method used

Image

Examples

Embodiment 1

[0075] G×-× gas well replacement damaged tubing workover operation

[0076] Firstly, calculate the required workover fluid density and dosage based on the formation pressure coefficient and wellbore structure of G×-× well; then, configure two workover fluid slugs; finally, carry out well killing and workover operations . The specific operation steps are as follows:

[0077] 1) Clean the liquid distribution tank, configure 8 m 3 Low solid phase water-locking type temporary plugging fluid slug and 180 m 3 Water-based anti-swell inhibitor slug.

[0078] 2) Check the blowout prevention pipeline. After passing the pressure test, release the pressure at the wellhead, and start to kill the well when the pressure drops below 5MPa.

[0079] 3) Inject a 5.0m water-based anti-swelling inhibitor slug from the oil jacket annulus 3 , and then inject a 5m slug of low solid phase water-locking temporary plugging fluid 3 , and then injected water-based anti-swelling inhibitor slug 25m ...

Embodiment 2

[0087] Lian × gas well bridge plug salvage and workover operations

[0088] Firstly, calculate the required workover fluid density and dosage according to the formation pressure coefficient and wellbore structure of the Lian× gas well; then, configure two workover fluid slugs; finally, carry out well killing and workover operations. The specific operation steps are as follows:

[0089] 1) Clean the liquid distribution tank, configure 5 m 3 Low solid phase water-locking type temporary plugging fluid slug and 150 m 3 Water-based anti-swell inhibitor slug.

[0090] 2) Check the blowout prevention pipeline. After the pressure test is qualified, the wellhead is ignited and blowout is started. When the pressure is released below 5MPa, the well killing will be carried out.

[0091] 3) Inject water-based anti-swelling inhibitor slug 3m from the oil jacket annulus 3 , and then inject a 5m slug of low solid phase water-locking temporary plugging fluid 3 , and then injected water-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com