Foam aluminum continuous extrusion foaming system

A technology of extruding foam and aluminum foam, which is applied in the field of continuous extrusion and foaming system of aluminum foam, which can solve the problems of uneven foaming inside and outside, slow drop of foaming melt temperature, etc., so as to reduce fluidity and avoid bubbles from floating up , the effect of controlling the rework rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

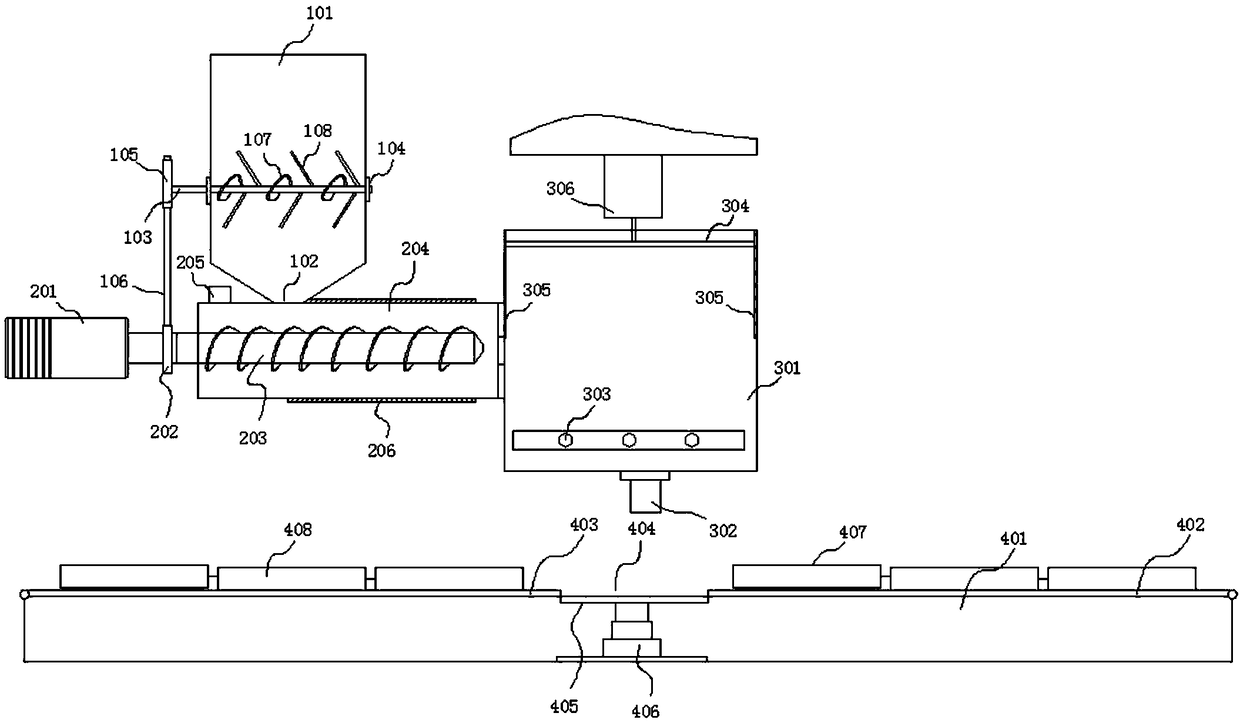

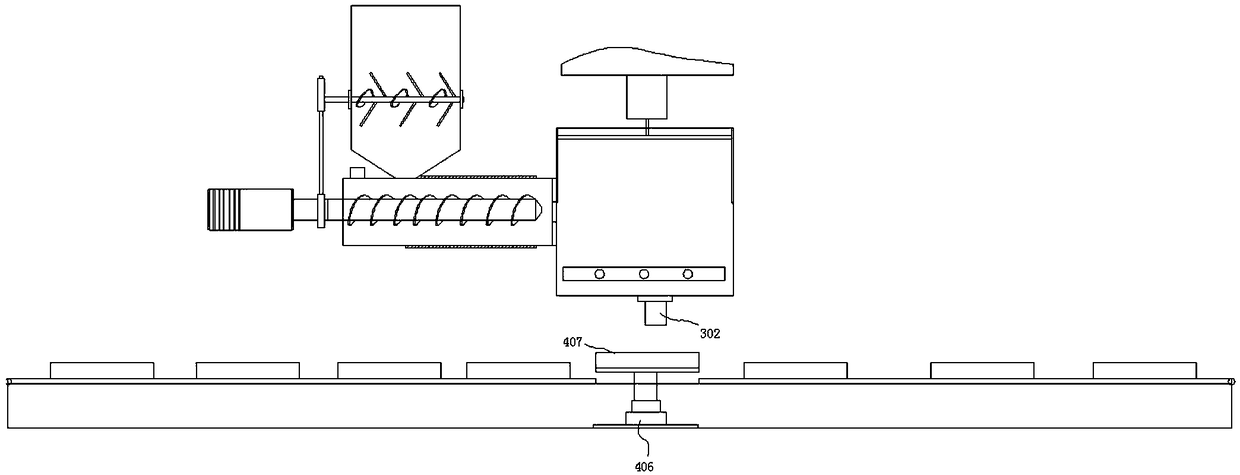

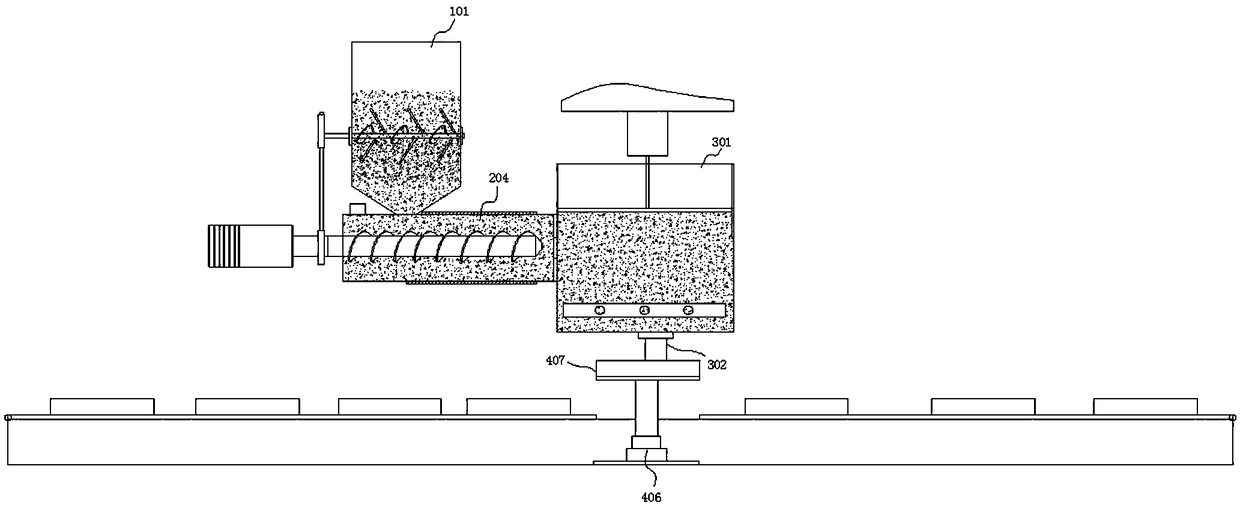

[0034] see Figure 1-4 ; A foam aluminum continuous extrusion foaming system, comprising:

[0035]The feeding bin 101 is used to store the thickened molten aluminum, and the bottom of the feeding bin 101 is provided with a discharge port 102; the lower part of the feeding bin 102 is horizontally provided with a stirring rod 103, and the two ends of the stirring rod 103 pass through Bearing assembly 104 is installed on the feed bin 101 side walls, and the power input end of stirring bar 103 is connected with driven gear 105, and driven gear 105 is connected to the driving gear 202 that is installed in drive motor 201 output ends by chain 106, by The driving motor 201 synchronously drives the propulsion screw 203 and the stirring rod 103 to rotate; The liquid is stirred, and the spiral protrusion 107 presses down the molten aluminum during the rotation and enters into the propulsion sleeve 204; at the same time, it also prevents the molten aluminum from clogging in the feeding ...

Embodiment 2

[0047] see Figure 1-4 ; A foam aluminum continuous extrusion foaming system, comprising:

[0048] The feeding bin 101 is used to store the thickened molten aluminum, and the bottom of the feeding bin 101 is provided with a discharge port 102; the lower part of the feeding bin 102 is horizontally provided with a stirring rod 103, and the two ends of the stirring rod 103 pass through Bearing assembly 104 is installed on the feed bin 101 side walls, and the power input end of stirring bar 103 is connected with driven gear 105, and driven gear 105 is connected to the driving gear 202 that is installed in drive motor 201 output ends by chain 106, by The driving motor 201 synchronously drives the propulsion screw 203 and the stirring rod 103 to rotate; The liquid is stirred, and the spiral protrusion 107 presses down the molten aluminum during the rotation and enters into the propulsion sleeve 204; at the same time, it also prevents the molten aluminum from clogging in the feeding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com