Double-power type automatic weft yarn clipping mechanism for woven fabric

A woven fabric, dual-power technology, applied in the direction of fabric surface trimming, textile and papermaking, thorn pattern, etc., can solve the problems of low production efficiency, high cost, many processes, etc., achieve low binding force, improve reliability, tension small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0043]The invention relates to a double-power type fabric cutting device for automatically cutting off the floating long thread on the surface of the fabric, which can drive the scissors to automatically cut the flower under the dual action of the winding force of the loom and the lifting force of the opening mechanism, and improve the cutting of the floating long thread of the weft. The yarn pile is reliable, and the fabric forms a similar imitation embroidery effect.

[0044] 1. Design and finishing of cut flowers

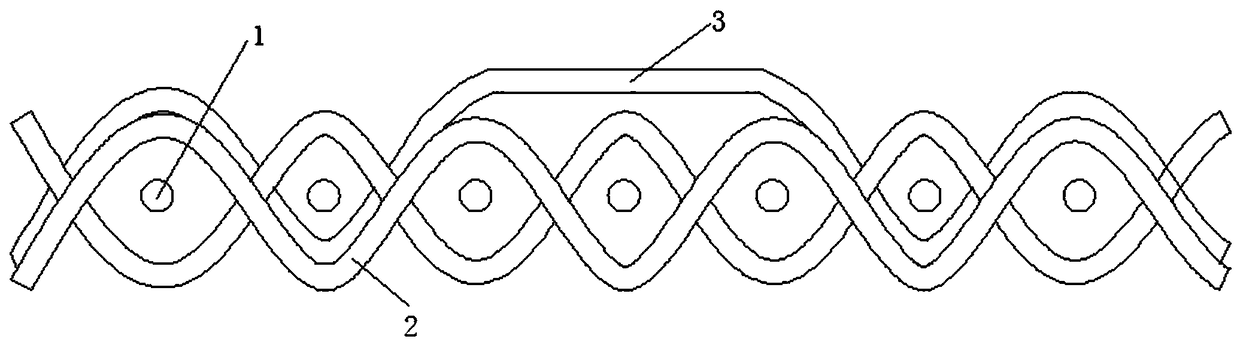

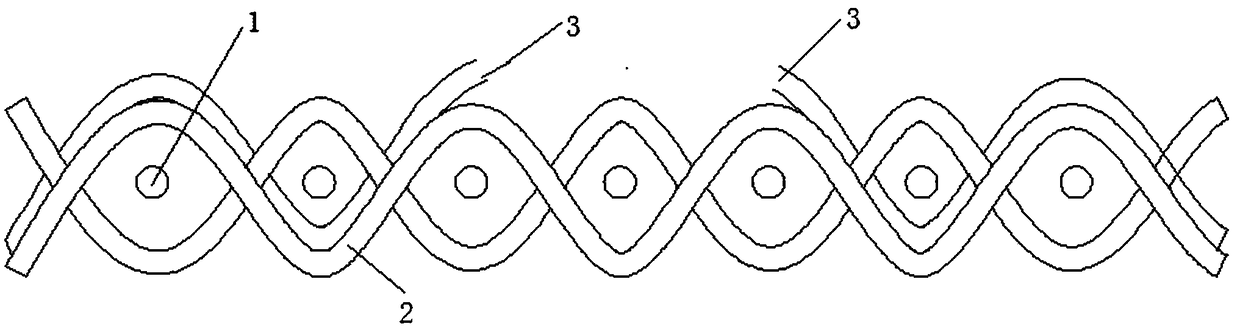

[0045] like figure 1 , The fabric is composed of plain weave and weft-raised weave based on weft-floating long thread. Plain weave is the skeleton and base fabric of the fabric, and does not undergo trimming. The knife is cut at both ends, such as figure 2 .

[0046] 2. The process of cutting extra weft of flower cutting mechanism

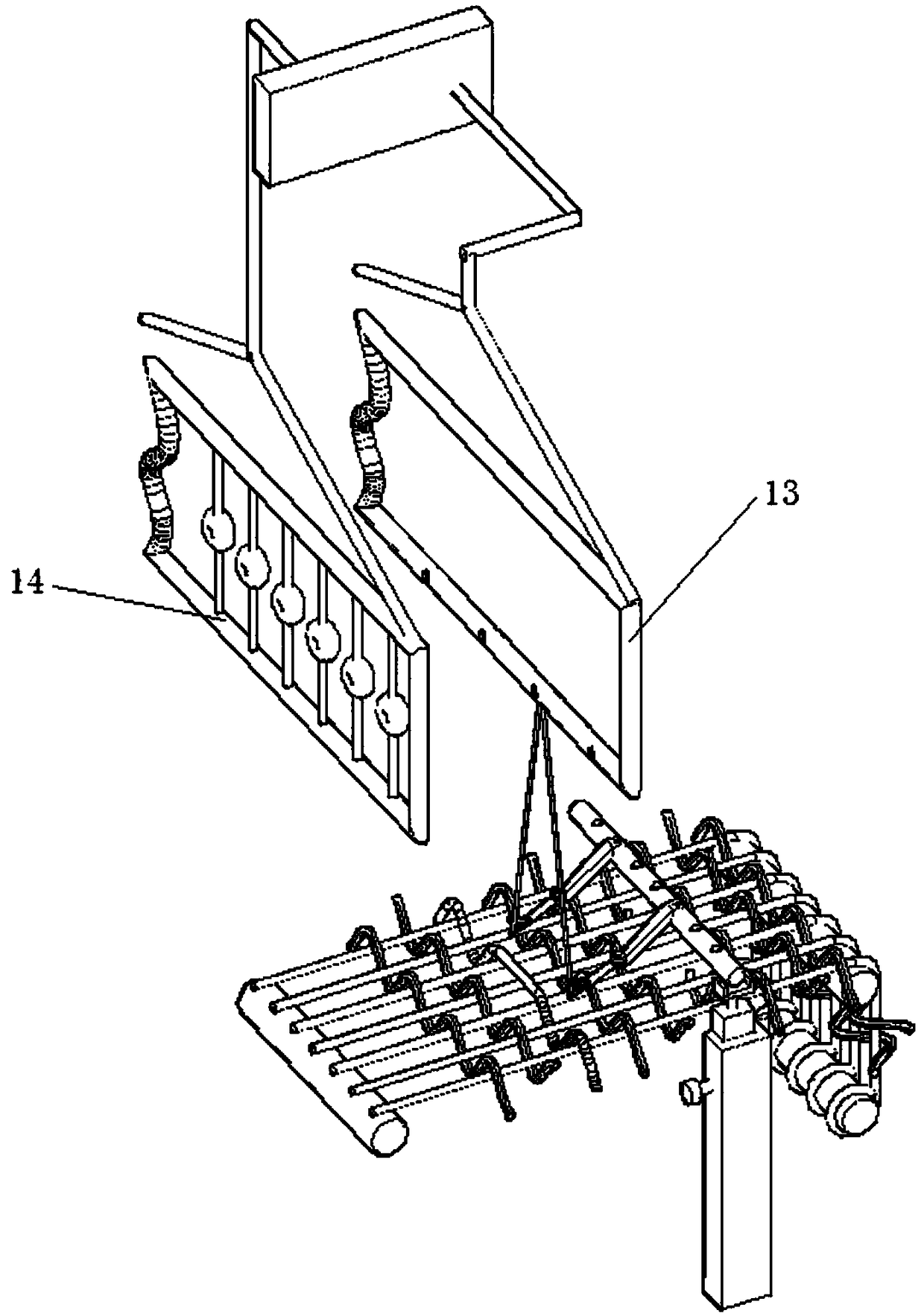

[0047] like Figure 3-9 It is a schematic diagram of the fabric cutting device. The warp yarn 1 enters the weaving area throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com