Track robot

A rail robot and rail wheel technology, applied to the track, track laying, track maintenance, etc., can solve the problems that affect the use of the track, difficult to handle, track corrosion, etc., and achieve the effect of improving stability, simple structure, and convenient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

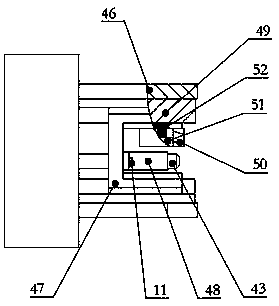

[0036] Embodiment 1: as Figure 1-22 As shown, a rail robot includes a rail wheel adjustment mechanism 1, a coating mechanism 2, a drive motor 4, a material spraying mechanism 6, an upper plate 7, a lower plate 9, a tensioning mechanism 10, a ferry mechanism 12, and a pulley mechanism 13 , belt 14; the lower plate 9 is installed on the upper plate 7, one end of the rail wheel adjustment mechanism 1 is installed between the upper plate 7 and the lower plate 9, and the tensioning mechanism 10 is installed on the upper plate 7 and the lower plate 9, the ferry mechanism 12 is installed between the upper plate 7 and the lower plate 9, the pulley mechanism 13 is installed on the lower plate 9 between the upper plate 7 and the lower plate 9, and the paint mechanism 2 is installed on the upper plate The part 7 is located at the tail of the upper plate part 7, the drive motor 4 is installed on the upper plate part 7, the output shaft of the drive motor 4 is connected with the pulley me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com