A method for installing a vertical prestressed steel hoop concrete assembly retaining wall for highways

A technology of vertical prestressing and installation methods, which is applied in the direction of clay preparation devices, chemical instruments and methods, supply devices, etc., can solve the problems of large construction area, poor impact resistance of retaining walls, and obstruction of road traffic, etc. Small excavation area, increased bearing capacity, and the effect of protecting driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

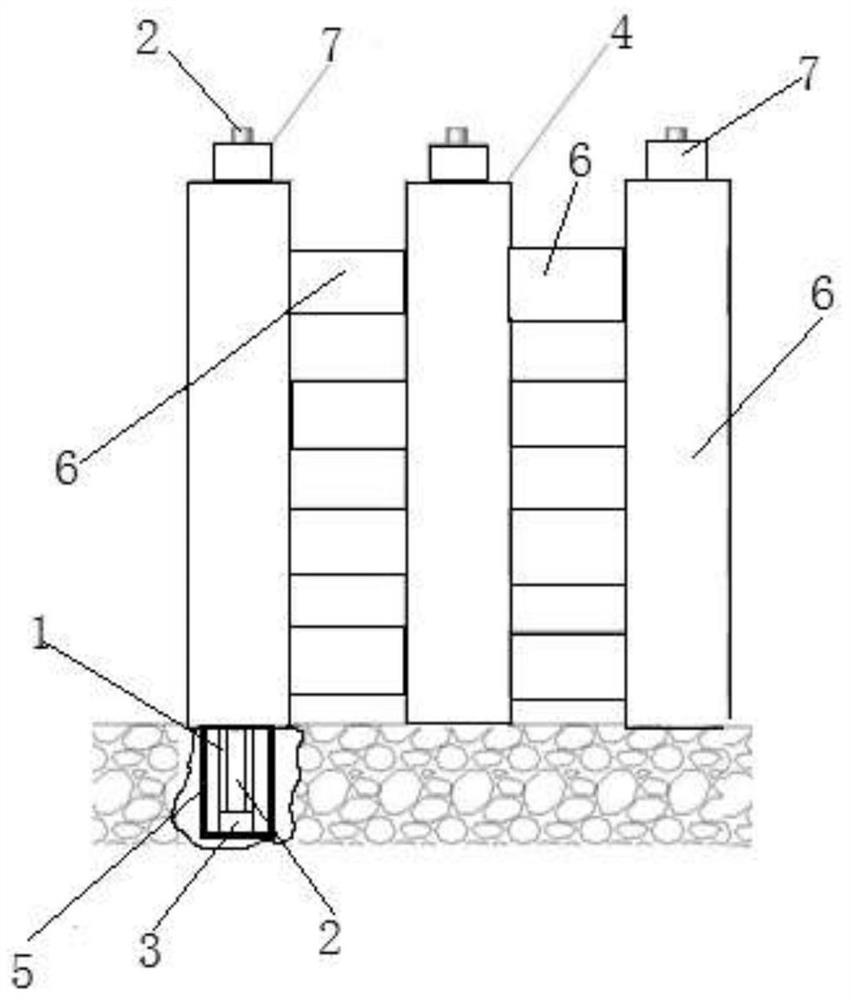

[0035] The present invention is a method for installing a vertical prestressed steel hoop concrete assembly type retaining wall for highways, see e.g. figure 1 As shown, it specifically includes the following steps:

[0036] Step 1. Drill holes on the construction site. The distance between adjacent holes is 2 to 3 meters. After the holes are laid out, check and make positioning marks. Then excavate the foundation trench at the marked hole positions. After reaching the base elevation, carry out scraping treatment on the surroundings of the foundation pit 5; pre-embed a vertically arranged PVC pipe 1 in each foundation pit 5, and the upper port of the PVC pipe 1 is flush with the upper surface of the foundation pit 5 ;

[0037] Step 2, apply semi-cohesive material evenly to the surface of the prestressing tendon 2;

[0038] The semi-adhesiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com