Inner partition board for constructions and preparation method thereof

A technology for partition boards and buildings, which is applied in construction, building materials, building components, etc. It can solve the problems of honeycomb bone spur boards, such as board defects, poor overall sound insulation effect, and weak rigidity, and achieve the goal of saving steel. High usage rate, high construction area utilization rate, and good decorative performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

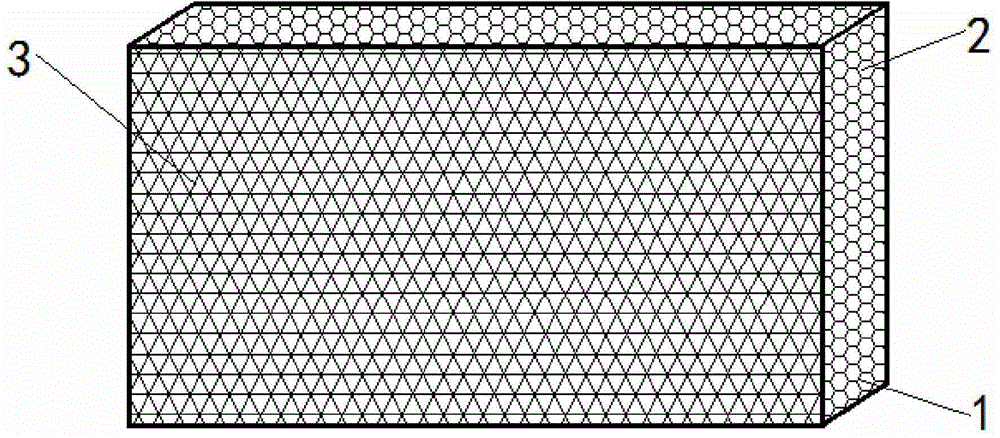

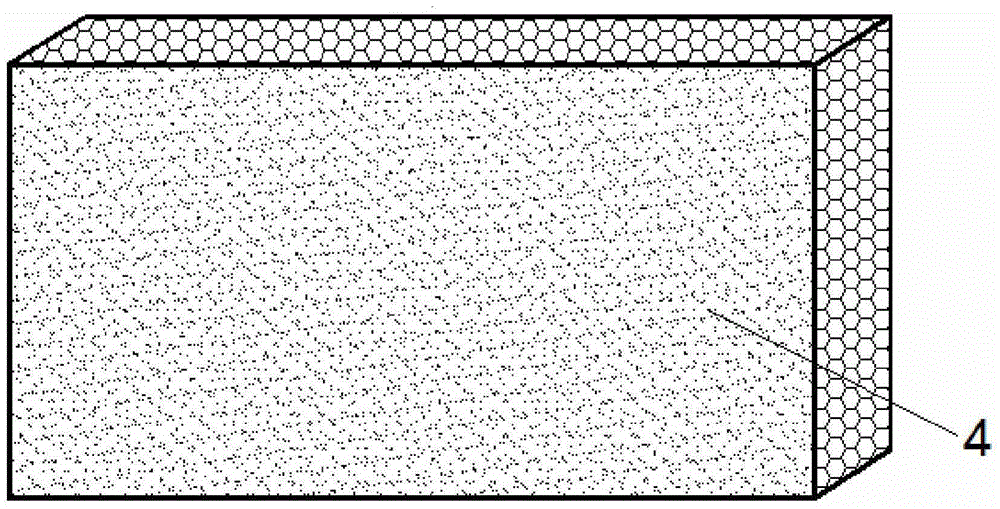

[0034] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, a building interior partition wall board, the board 1 is composed of honeycomb spurs 2, and the surface 3 of the board 1 has a plastering surface 4.

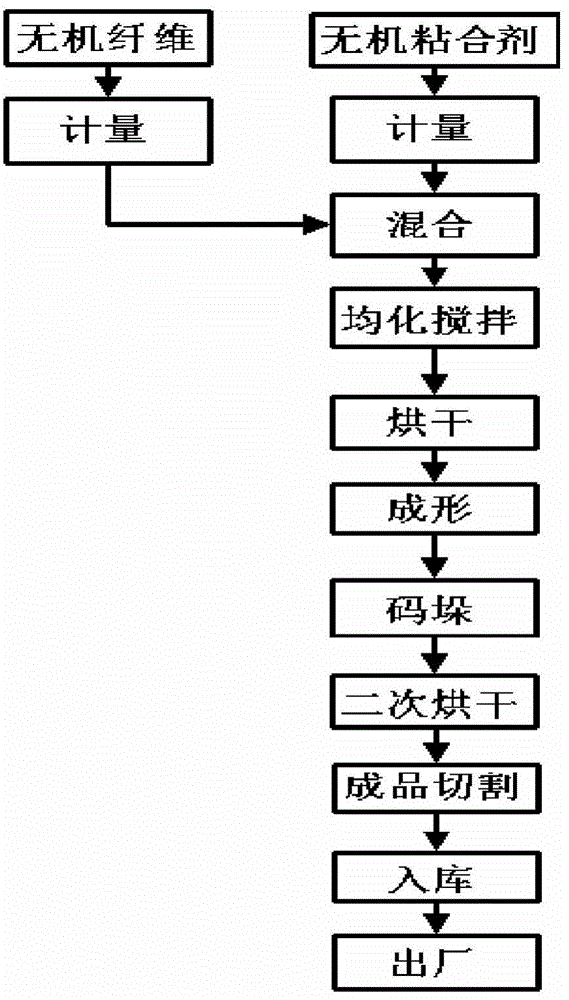

[0035] A method for preparing a building interior partition board; comprising the following steps;

[0036] Step 1, mixing the inorganic fiber and the inorganic binder after weighing respectively;

[0037] Step 2. Stir evenly;

[0038] Stirring in the first step: adding additives (polyester environmental protection glue molding and curing); the weight of additives is 10% of the weight of inorganic fibers and inorganic binders;

[0039] Stirring in the second step: adding additives (polyester environment-friendly glue molding and curing); the weight of additives is 100% of the weight of inorganic fibers and inorganic binders;

[0040] Step 3, put it into a heating furnace for drying, and the drying temperature is 130°C;

[0041] Step 4, forming a honeycomb sp...

Embodiment 2

[0049] Embodiment 2: as figure 1 , figure 2 , image 3 As shown, a building interior partition wall board, the board 1 is composed of honeycomb spurs 2, and the surface 3 of the board 1 is provided with a plastering surface 4 or connected with a gypsum board.

[0050] A method for preparing a building interior partition board; comprising the following steps;

[0051] Step 1, mixing the inorganic fiber and the inorganic binder after weighing respectively;

[0052] Step 2. Stir evenly;

[0053] Stirring in the first step: adding additives (polyester environmental protection glue molding and curing); the weight of additives is 10% of the weight of inorganic fibers and inorganic binders;

[0054] Stirring in the second step: adding additives (polyester environment-friendly adhesive molding and curing); the weight of additives is 90% of the weight of inorganic fibers and inorganic binders;

[0055] Step 3, put it into a heating furnace for drying, and the drying temperature i...

Embodiment 3

[0060] Embodiment 3: as figure 1 , figure 2 , image 3 As shown, a building interior partition wall board, the board 1 is composed of honeycomb spurs 2, and the surface 3 of the board 1 has a plastering surface 4.

[0061] A method for preparing a building interior partition board; comprising the following steps;

[0062]Step 1, mixing the inorganic fiber and the inorganic binder after weighing respectively;

[0063] Step 2. Stir evenly;

[0064] Stirring in the first step: adding additives (polyester environmental protection adhesive molding and curing); the weight of additives is 8% of the weight of inorganic fibers and inorganic binders;

[0065] Stirring in the second step: add additives (polyester environmental protection glue molding and curing); the weight of additives is 88% of the weight of inorganic fibers and inorganic binders;

[0066] Step 3, put it into a heating furnace for drying, and the drying temperature is 140°C;

[0067] Step 4, forming a honeycomb ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com