A rapid construction method for composite joints of non-precipitation large-diameter winding pipes

A construction method and large-diameter technology, which are applied in water conservancy projects, sewer pipeline systems, artificial islands, etc., can solve the problems of water seepage and leakage at the pipe body interface, and the connection between the inspection well and the pipe mouth is not tight, so as to achieve lightweight material quality and avoid manhole covers. Subsidence, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiments. It should be pointed out that the following embodiments are only explanatory descriptions of the present invention in the form of examples, but the protection scope of the present invention is not limited thereto. Equivalent replacements made by the skilled person to the present invention based on the spirit of the present invention all fall within the protection scope of the present invention.

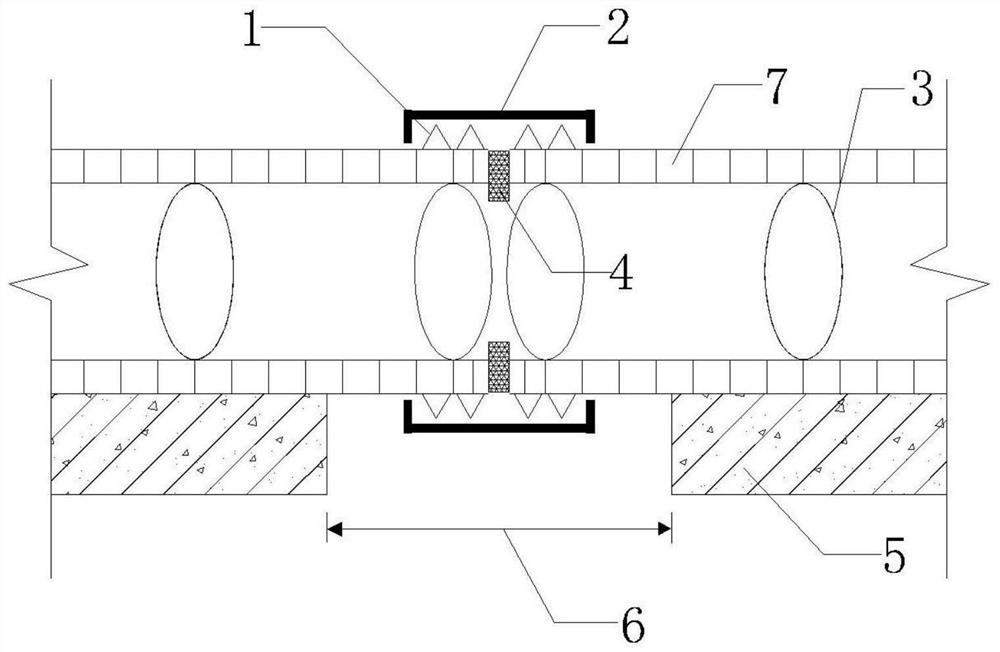

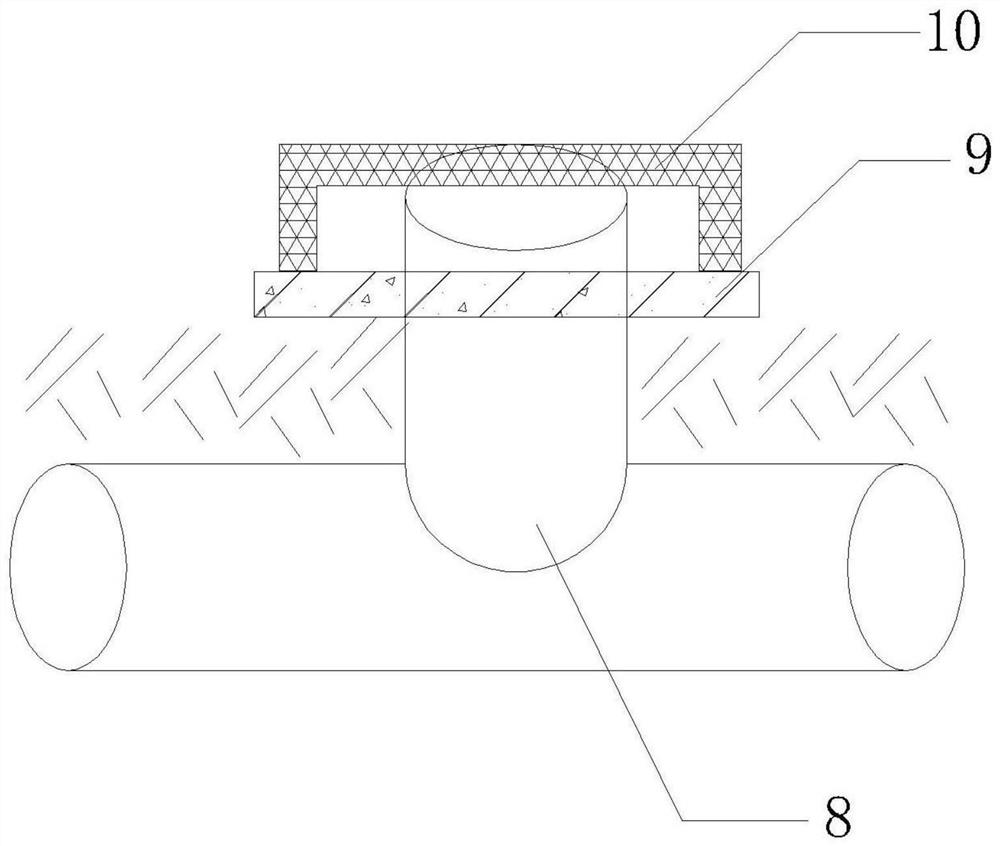

[0031] refer to figure 1 with figure 2 , a rapid construction method for composite joints of non-precipitation large-diameter winding pipes disclosed by the present invention, comprising the following steps:

[0032] S1. Pipe trench excavation

[0033] According to the design height of the trench, select the grading coefficient for grading excavation. The slope is preferably 1:0.5, and the width of the working face is ≥0.3m. Stone preparation to two meters away from the side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com