Screw vacuum pump with built-in nitrogen seal at exhaust side

A screw vacuum pump, nitrogen sealing technology, applied in the sealing device of piston pump, pump, pump components, etc., can solve the problems of nitrogen consumption, nitrogen leakage, affecting the quality of raw gas, etc., to prolong the service life and protect from damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

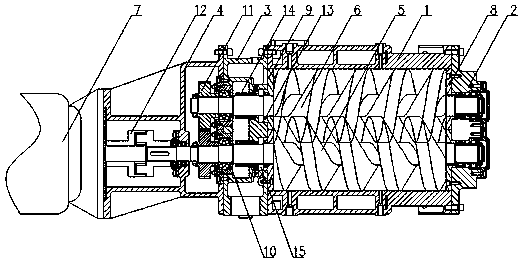

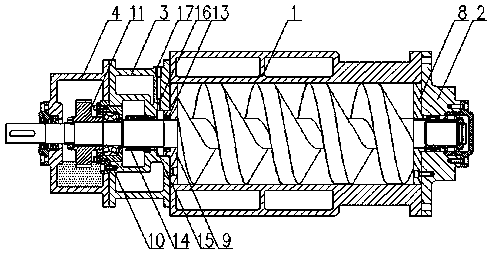

[0013] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

[0014] Such as figure 1 , 2, the exhaust side built-in nitrogen-sealed screw vacuum pump, including pump body 1, front housing 2, rear housing 3, gear box 4, driving rotor 5, driven rotor 6, motor 7. The front casing 2 is installed on the intake side of the pump body 1 through the positioning flange 8, the rear casing 3 is installed on the exhaust side of the pump body 1 through the exhaust guide plate 9, and the exhaust guide plate 9 is positioned and connected to the Pump body 1 and rear casing 3. The driving rotor 5 and the driven rotor 6 are fixed and installed in the pump body 1 in parallel. One end of the driving and driven rotors 5 and 6 is supported on the front casing 2 by cylindrical roller bearings, and the other end is supported on the rear by double row angular contact ball bearings. shell3. The gear box 4 is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com