Hub reduction type double-speed driving axle

A wheel-side deceleration and drive-axle technology, applied in the differential transmission, transmission, belt/chain/gear, etc., can solve the problems of insufficient full-load torque, insufficient no-load speed, etc., to improve driving torque, improve efficiency, The effect of reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

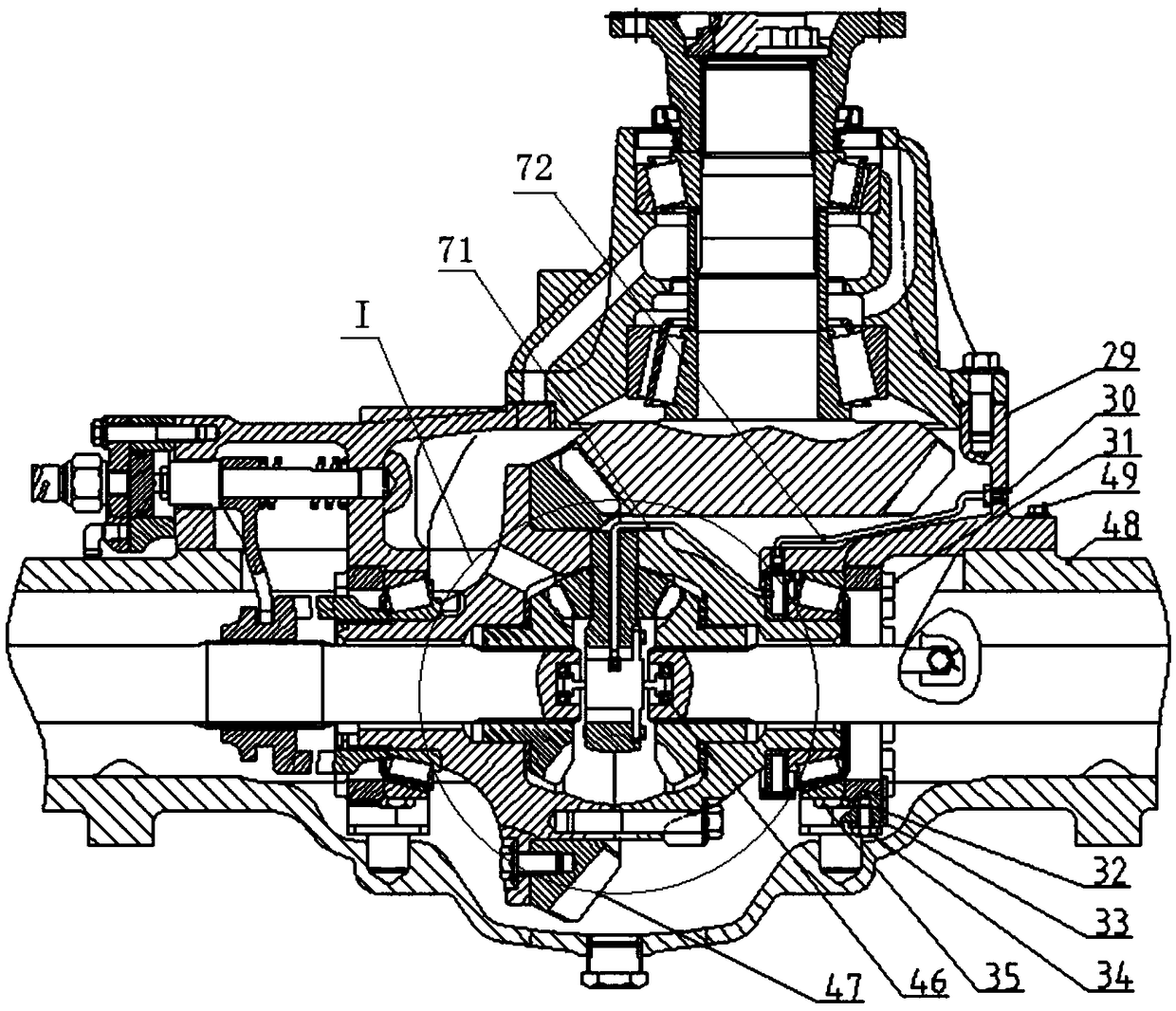

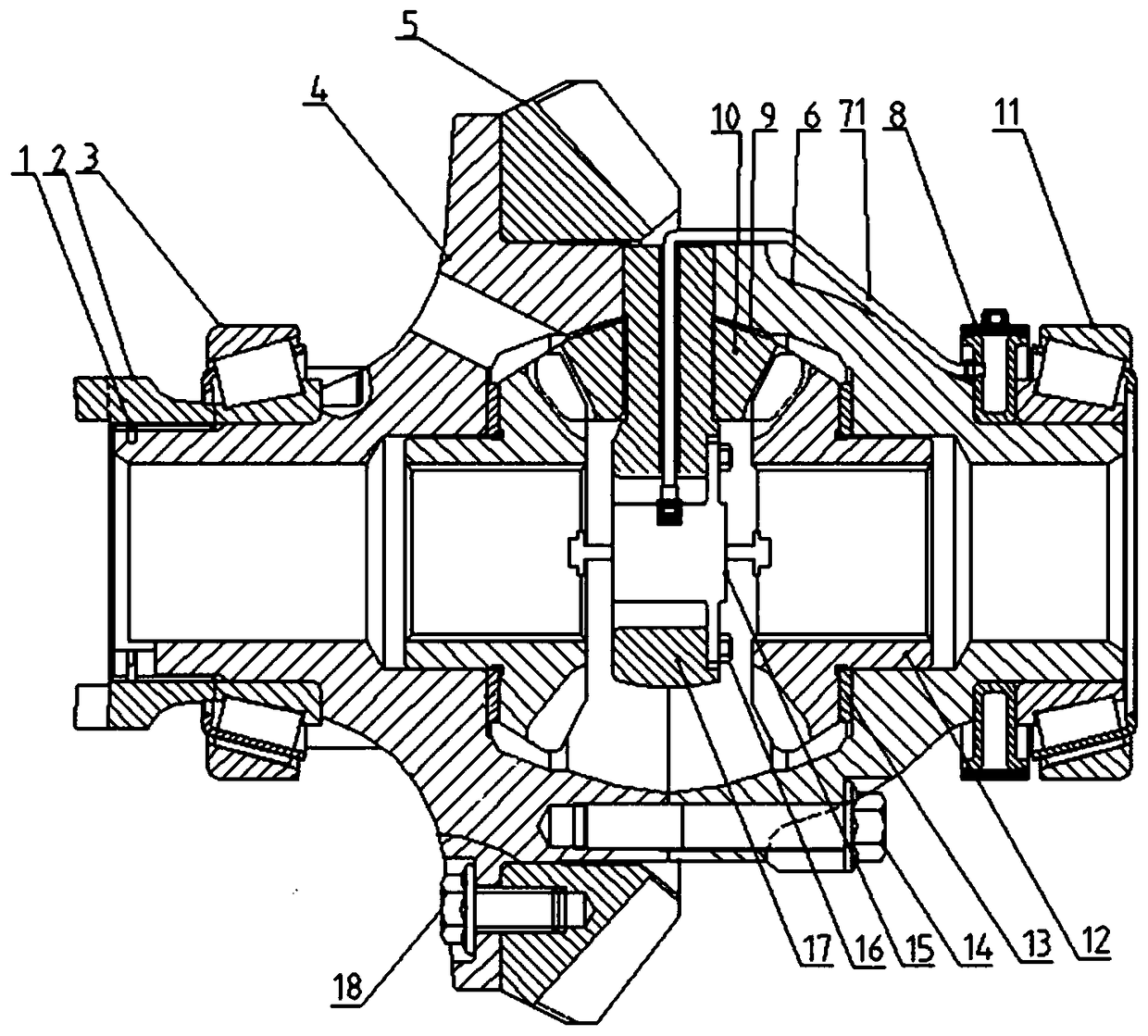

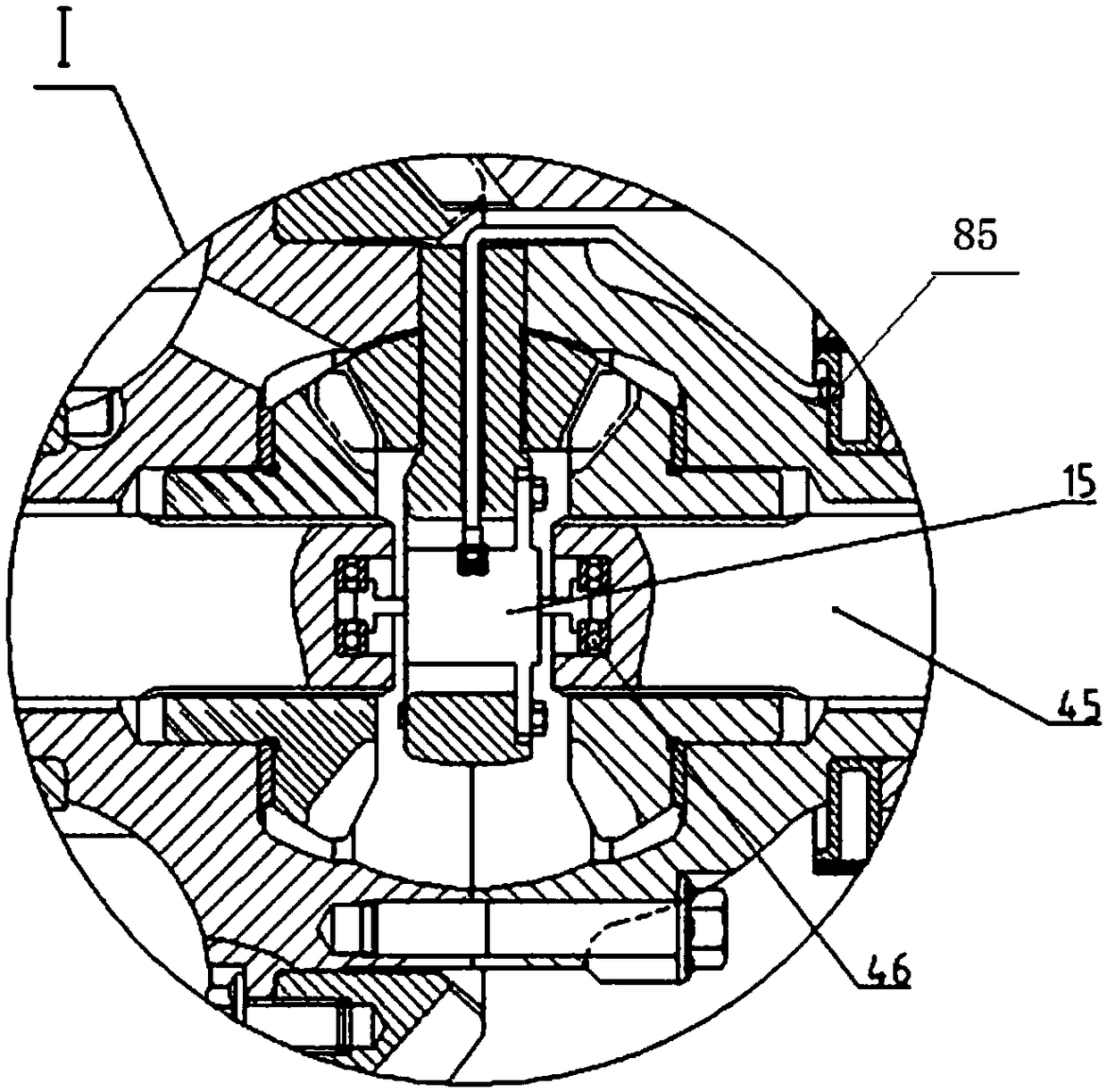

[0029] There are left and right half shafts in the drive axle assembly, and the two half shafts are installed in the axle housing assembly 48, and the whole drive axle assembly has the same structure at the ends of the two half shafts; The present invention will be described in detail by taking an example.

[0030] like figure 1 As shown, the bearing diameter of the differential assembly 47 is installed in the semicircular hole of the reducer housing 29, and the semicircular hole of the differential bearing cover 32 is installed on the bearing diameter of the differential assembly 47, through four bolts 35 Connect and fix the differential bearing cover 32 and the reducer housing 29; the end of the differential bearing cover 32 is equipped with an adjusting ring 31, and the adjusting ring 31 is radially locked by the locking piece 33, and the locking piece 33 is fixed by the bolt 34; The main gear 100 meshes with the driven bevel gear 5; the plane of the reducer housing 29 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com