Pipeline fastening clamping ring and machining technology

A processing technology and fastening card technology, applied in the direction of pipeline connection layout, pipe/pipe joint/pipe fittings, mechanical equipment, etc., can solve the problems of easy cutting, large proportion of pipe fittings, high price of brass material per ton, and increase friction. The effect of force and anti-backoff, preventing the existence of gaps, and strong workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

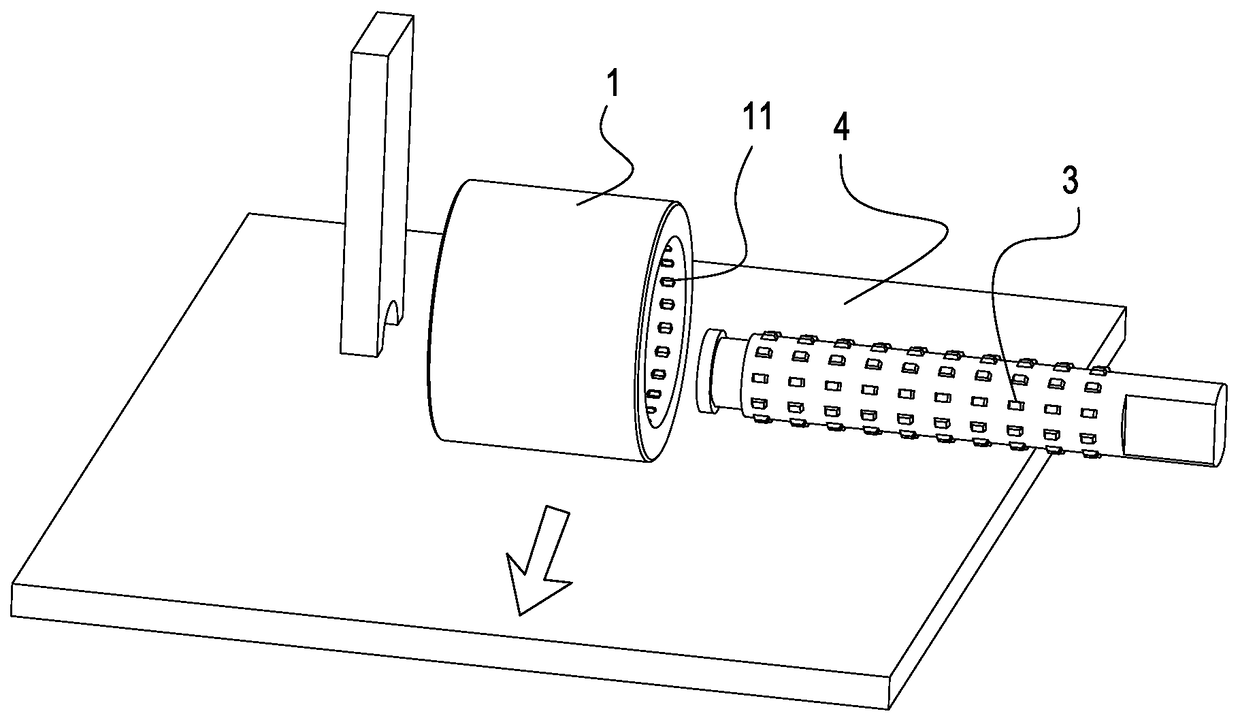

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

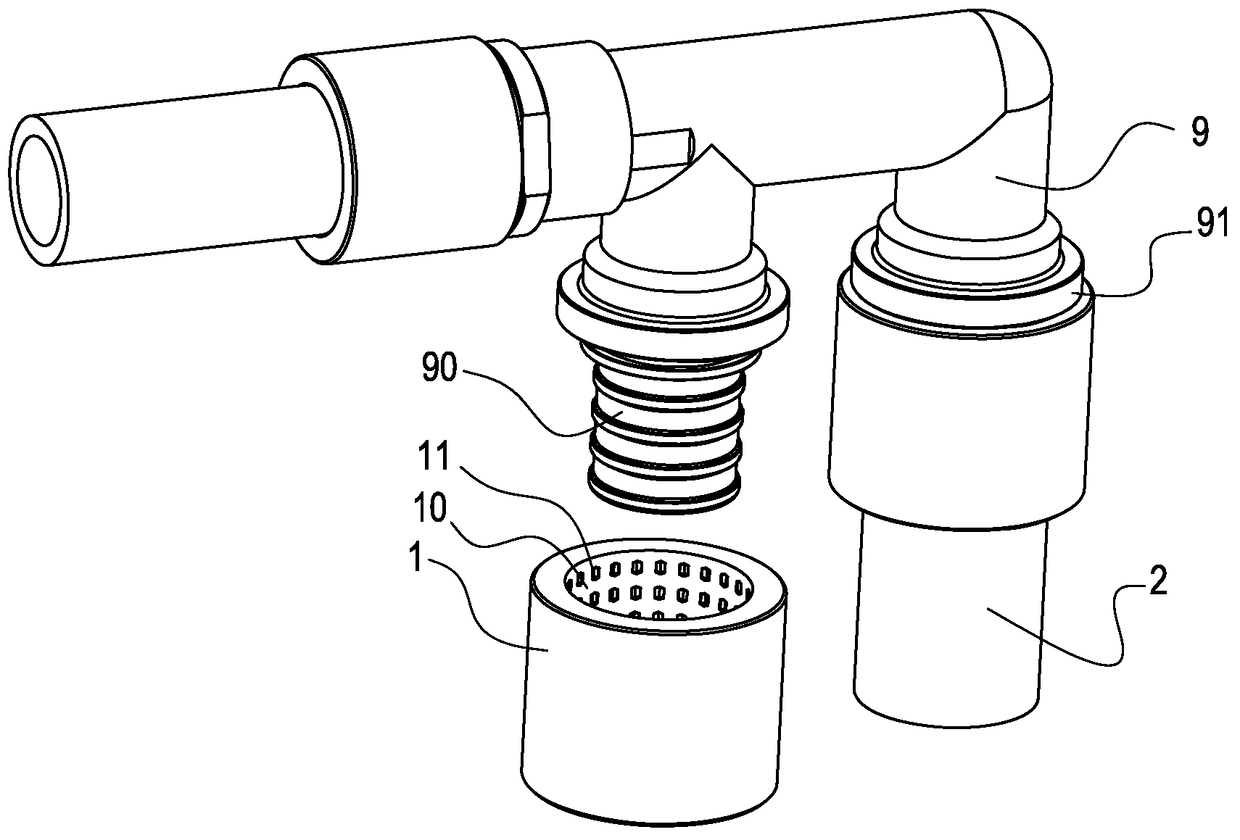

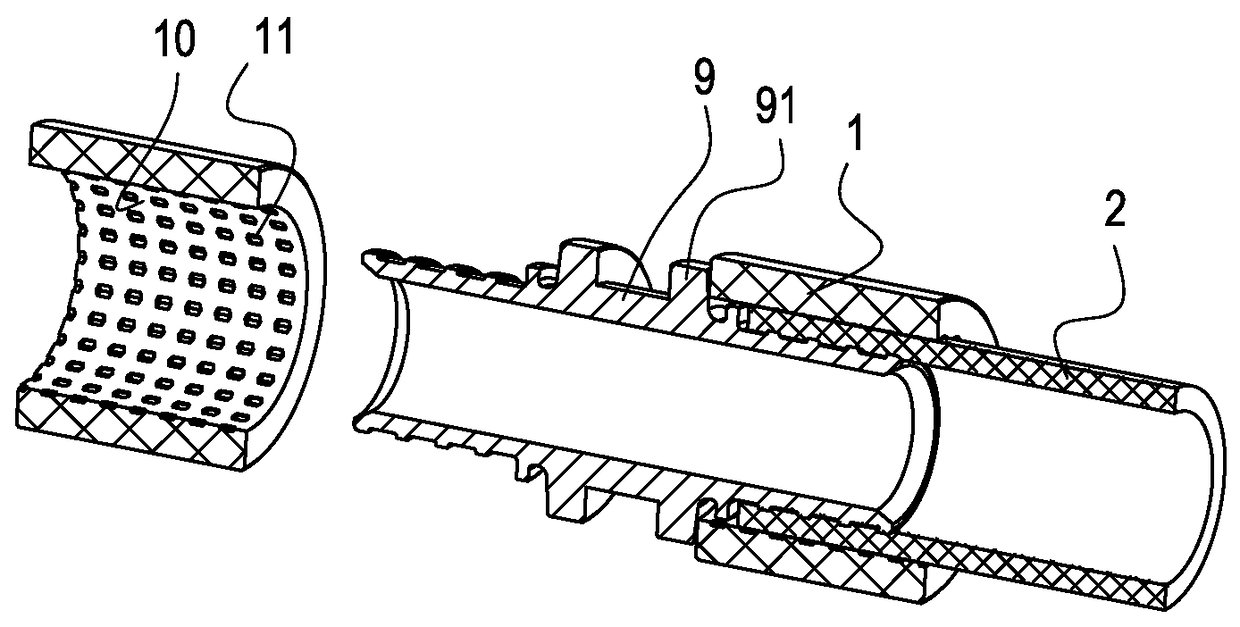

[0025] Such as figure 1 with figure 2 As shown, a pipe fastening collar, the collar 1 is a cylindrical ring structure, the diameter of the inner wall 10 of the collar 1 is matched with the outer diameter of the matching pipe 2, and the collar 1 is made of cross-linked polyethylene material with strong shrinkage There is no chamfer structure at the front end of the inner wall of the collar 1; knurl teeth 11 are provided on the inner wall 10 of the collar 1.

[0026] Compared with the existing technology of sliding and tightening pipe fittings, the pipe fitting main body 9 of the present invention is consistent with the prior art, the collar is made of non-metallic material, and the cross-linked polyethylene material itself is a high-temperature and weather-resistant material with high resilience and holding capacity. Tightening force, expansion of more than 15%, retr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com