Mounting base for industrial robot

A technology for installing bases for industrial robots, which is applied in the direction of engine bases, supporting machines, mechanical equipment, etc., can solve problems such as inability to adapt to robots of various sizes, lack of shock absorbing devices, and shorten the service life of machines, so as to improve the scope of application. Shock absorption effect, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

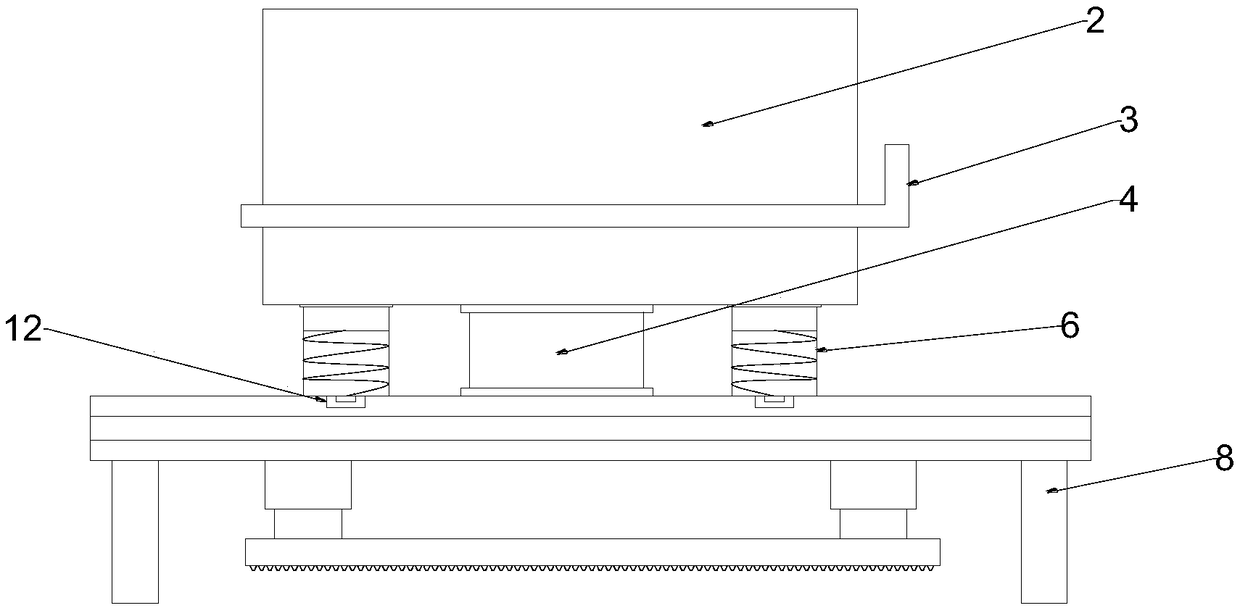

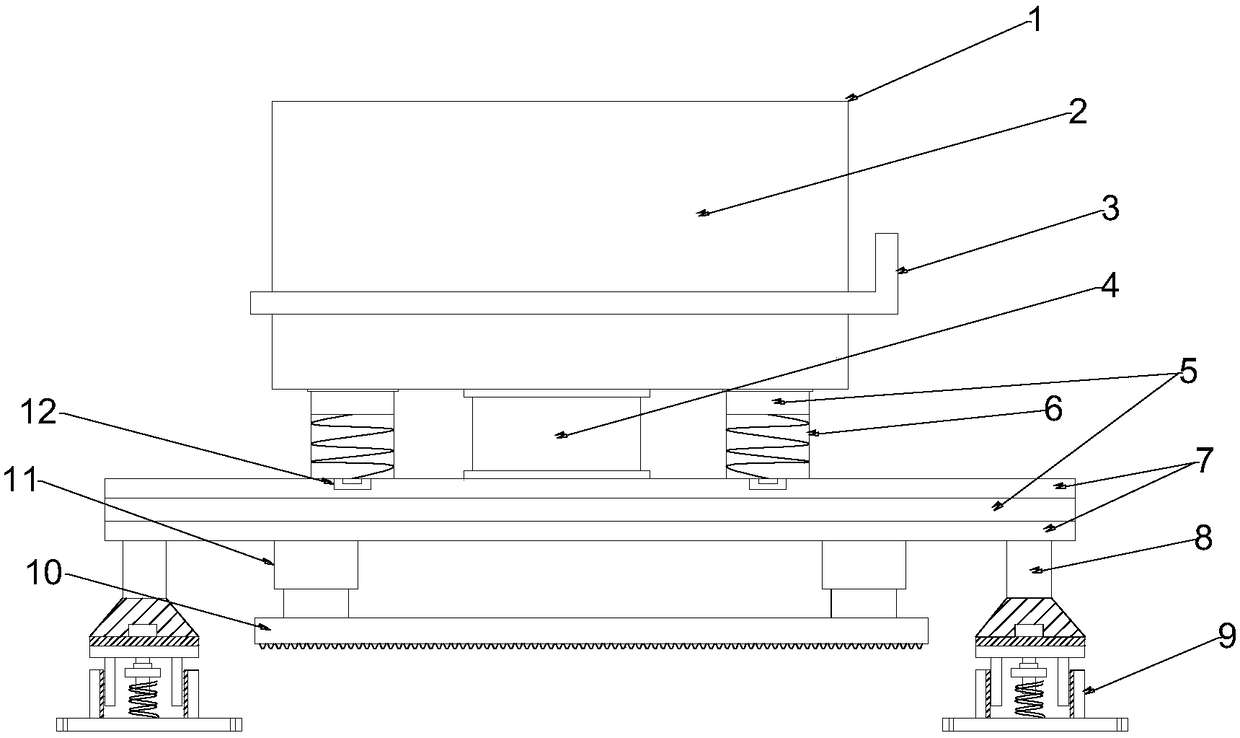

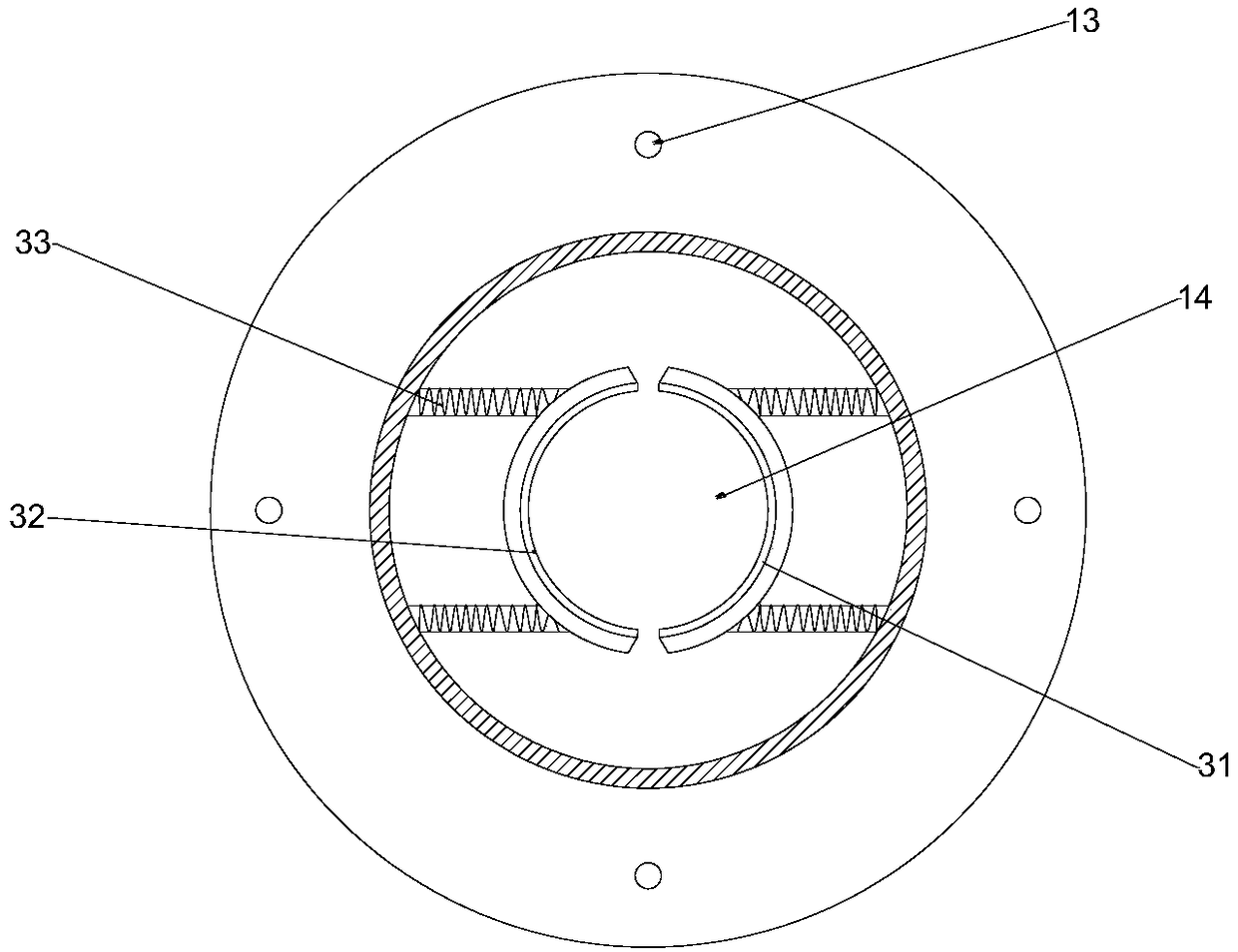

[0021] see Figure 1-2 , in an embodiment of the present invention, a mounting base for an industrial robot includes a robot mounting base 2, the top plate of the robot mounting base 2 is provided with a limiting groove 14 and a fixing bolt hole 13, and the fixing bolt hole 13 is located at the robot mounting base At the four corners of 2, a rotating handle 3 is provided on the outer wall of the robot mounting base 2, the bottom of the robot mounting base 2 is fixedly connected with the rotating shaft 4, and the rotating direction can be rotated by the rotating handle 3, and the two sides of the rotating handle A shock absorber 6 is provided, and the shock absorber 6 is fixedly connected with the robot mounting base 2. The shock absorber 6 can effectively reduce the vibration generated when the robot works. The bottom of the shock absorber 6 is provided with a track 12, and the track 12 The shock absorbing device 6 is rotated together with the robot mounting base 2, and the up...

Embodiment 2

[0025] see figure 1 , in the embodiment of the present invention, on the basis of embodiment 1, a shock-absorbing base 9 is added, and the shock-absorbing base 9 includes a hydraulic controller 20, screws 21, a first rubber pad 22, an upper fixing piece 23, and an inner limit Block 24, limit fixed foot 25, outer limit block 26, second rubber pad 27, first spring 28, buckle 29, nut 30, and the top of described damping base 9 is provided with screw 21, and described screw 21 and The upper fixing piece 23 is connected by bolts, the upper fixing piece 23 is provided with a first rubber pad 22, and the upper fixing piece 23 is provided with an inner limiting block 24, and the inner limiting piece 24 is in contact with the upper fixing piece 23. Welding, the middle of the inner limiting block 24 is provided with a buckle 29, the buckle 29 is detachably connected with the first spring 28 through a nut 30, and the outer side of the inner limiting block 24 is provided with a second rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com