Leakage-proof waste incineration reciprocating fire grate

A reciprocating grate and waste incineration technology, applied in the field of incinerators, can solve the problems of poor deformation resistance, easy leakage of material and ash, inconvenient maintenance, etc., achieve high beam strength, increase service life, and reduce slag and ash leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments: taking this as an example to further describe and illustrate the present application.

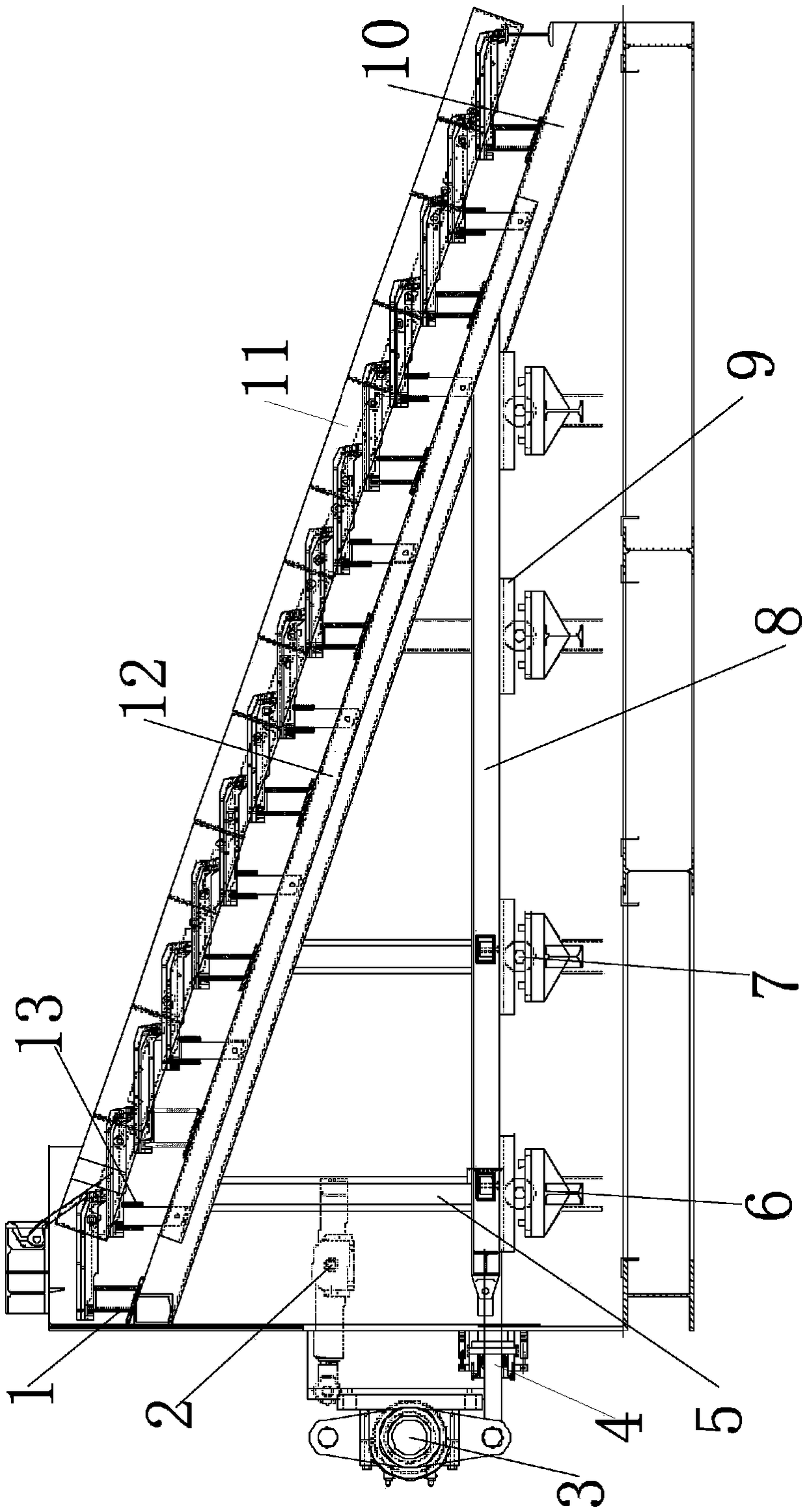

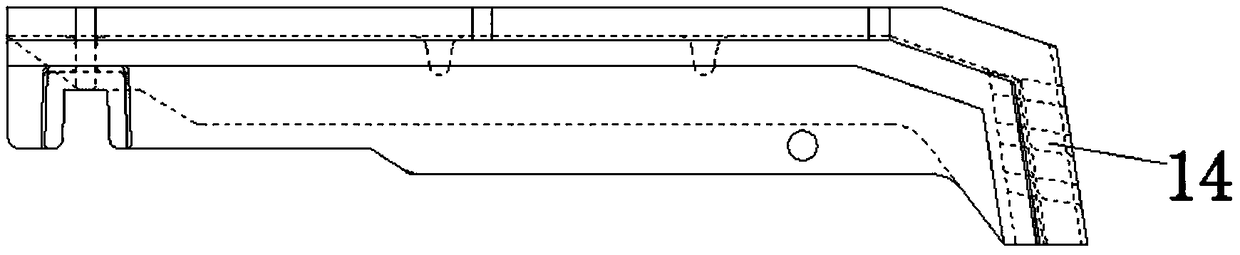

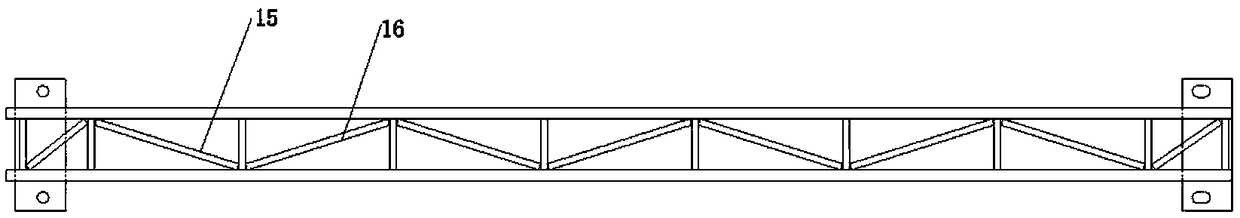

[0017] Such as Figure 1-4 As shown, this embodiment provides a leak-proof garbage incineration reciprocating grate, including: frame, movable frame, crank linkage mechanism, hydraulic cylinder, connecting shaft, grate piece, movable beam, fixed beam, steel plate, roller, support frame , side sealing block; the movable frame is located in the frame, and the movable frame includes: connected bottom beams and movable inclined beams, several reinforcing beams are arranged between the bottom beams and the movable inclined beams, and the movable inclined beams are installed on On the frame, there are several steel plates under the bottom beam, and there are rollers between each steel plate and the support frame. There are two hydraulic cylinders, which ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com