Vacuum system field calibration method based on wireless transmission

A vacuum and wireless technology, used in measuring devices, instruments, measuring fluid pressure, etc., can solve the problems of equipment performance, life, accuracy, operator's personal health, etc., to protect personal health and safety, save costs, and low power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

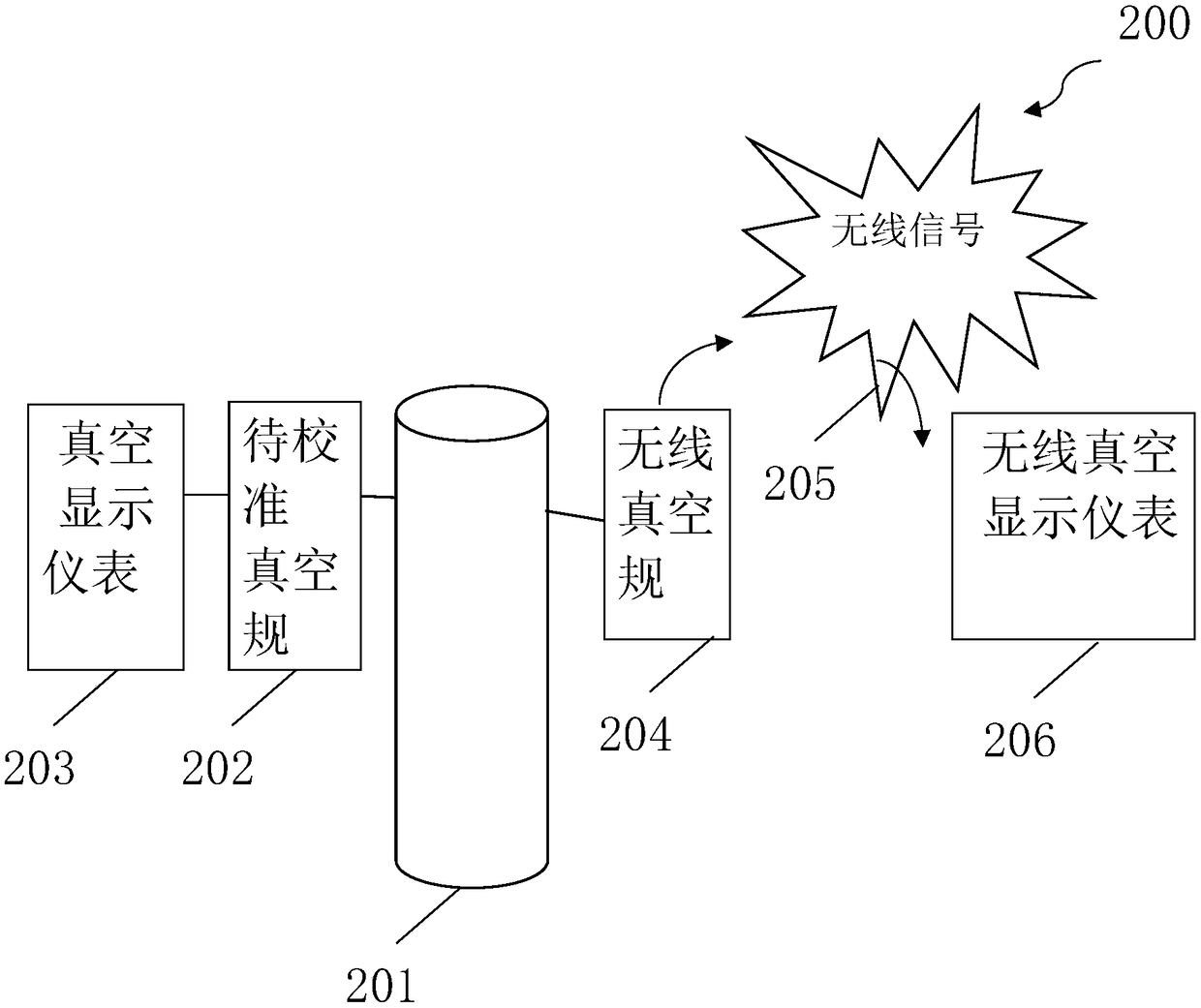

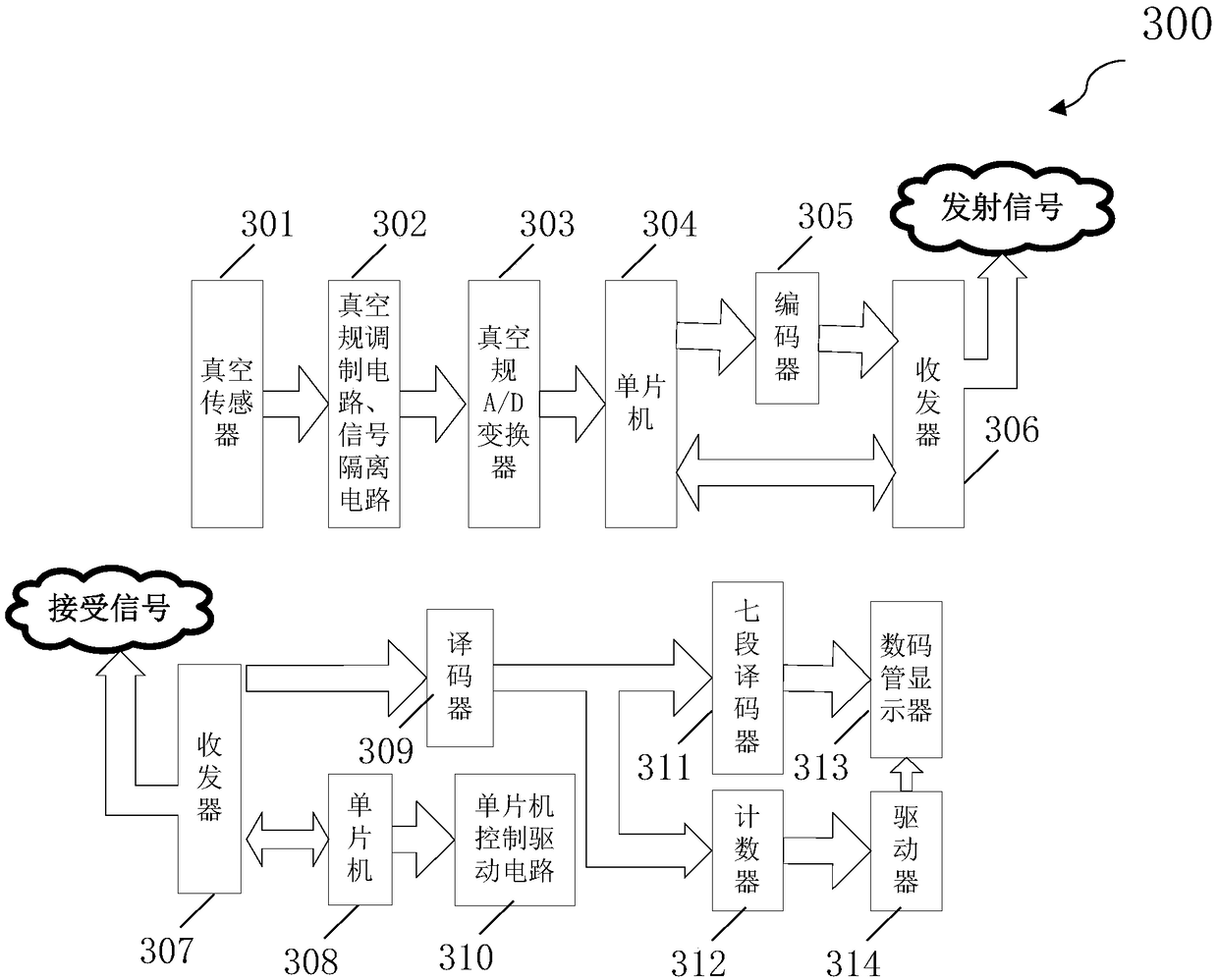

[0020] At least in order to improve the efficient transmission of vacuum data related to the vacuum degree in the vacuum system, simplify the design complexity and cost of the system, and protect the personal safety of the staff, the embodiments of the present invention propose a system for vacuum-related monitoring of the environment. In one embodiment, the system uses wireless vacuum gauges (or wireless sensors) arranged at one or more locations in the environment to collect vacuum data, and uses a wireless transmission module to send the vacuum data to a remote vacuum degree communication terminal . In one embodiment, a wireless vacuum gauge can be used to calibrate the working vacuum gauge in the environment, so as to ensure the accuracy of the working vacuum gauge.

[0021] The following will combine Figure 1-Figure 4 To specifically describe the technical solution of the present invention.

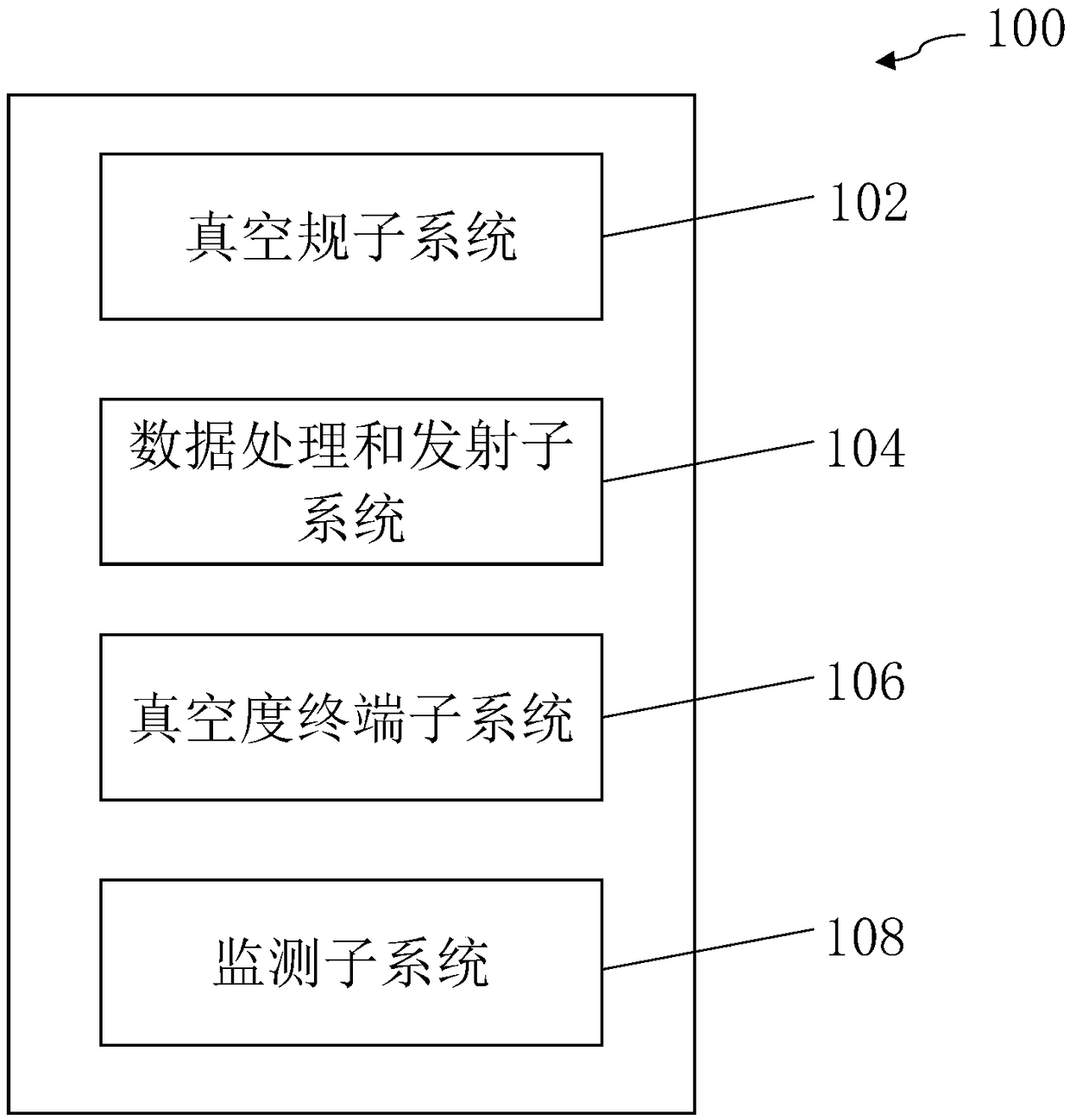

[0022] figure 1 is a schematic block diagram illustrating a system 100 for v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com