Hall current sensor skeleton

A Hall current and sensor technology, which is applied in the field of sensor skeleton, can solve the problems of poor environmental adaptability and large space occupation, and achieve the effect of reducing the occupied volume, not reducing the accuracy, and improving the environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention aims to provide a skeleton of a Hall current sensor to solve the technical problems in the prior art that the skeleton of a Hall current sensor occupies a large space and has poor environmental adaptability.

[0022] In order to enable those skilled in the art to better understand the present invention, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

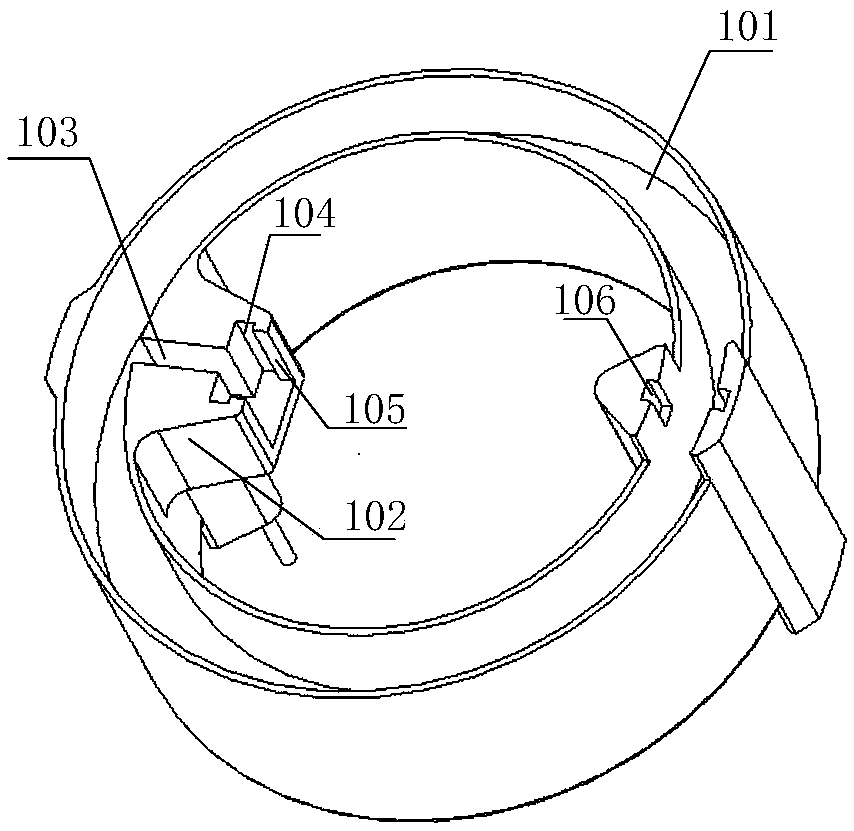

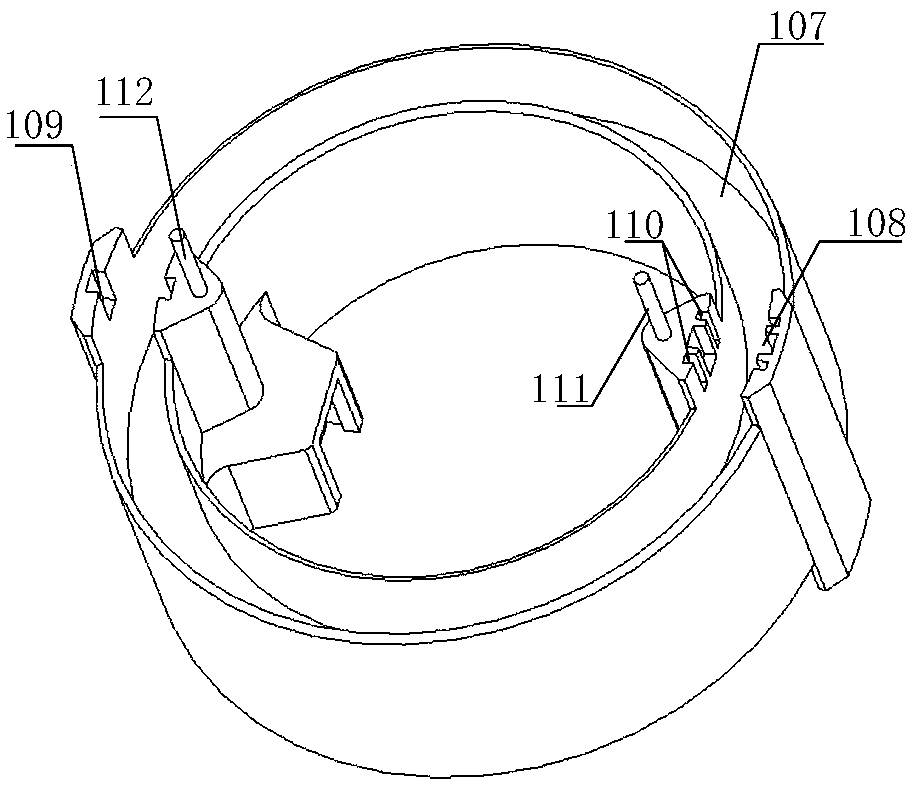

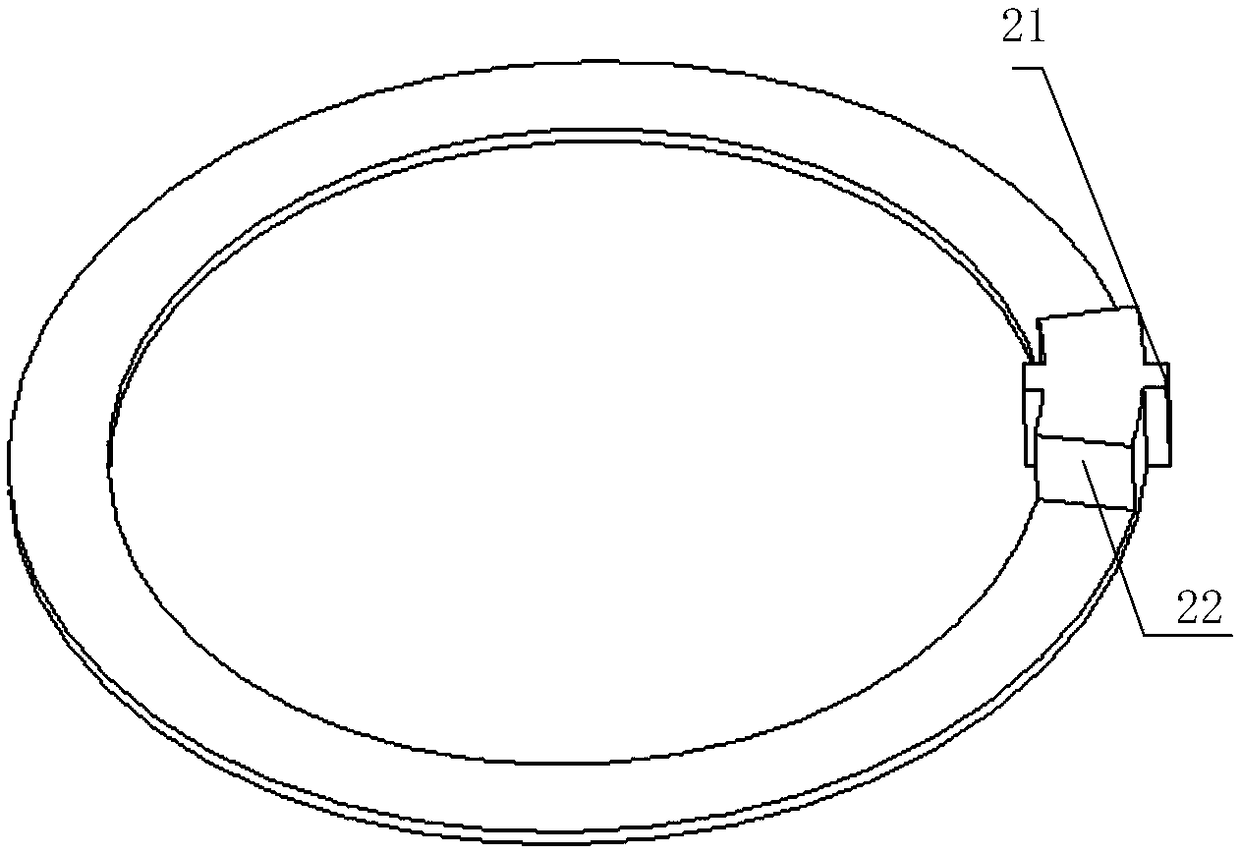

[0023] A Hall current sensor skeleton, comprising a skeleton shell, the upper and lower ends of the skeleton shell are provided with annular magnetic core installation grooves 101 and 107, the upper and lower two annular magnetic core installation grooves are not connected to each other, and are used to install two A coaxial magnetic core, a fixed boss 102 is arranged on the inner wall of the skeleton housing, and a Hall assembly is installed on the fixed boss, and the Hall assembly includes a first Hall element 41, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com