Device for quickly replacing radial magnetizing coil

A magnetizing coil, fast technology, applied in the direction of magnetic objects, electrical components, circuits, etc., can solve the problem of high cost, achieve the effect of preventing misoperation, easy to use, and rich in functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

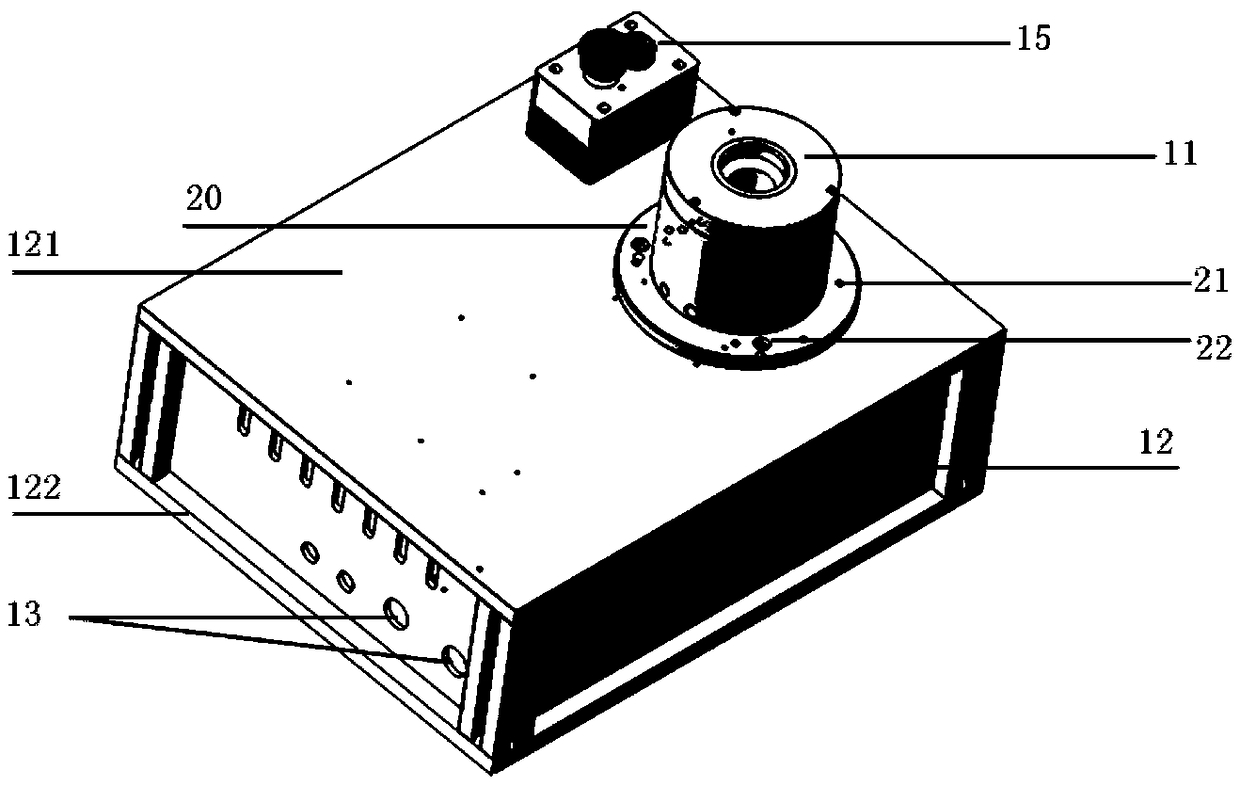

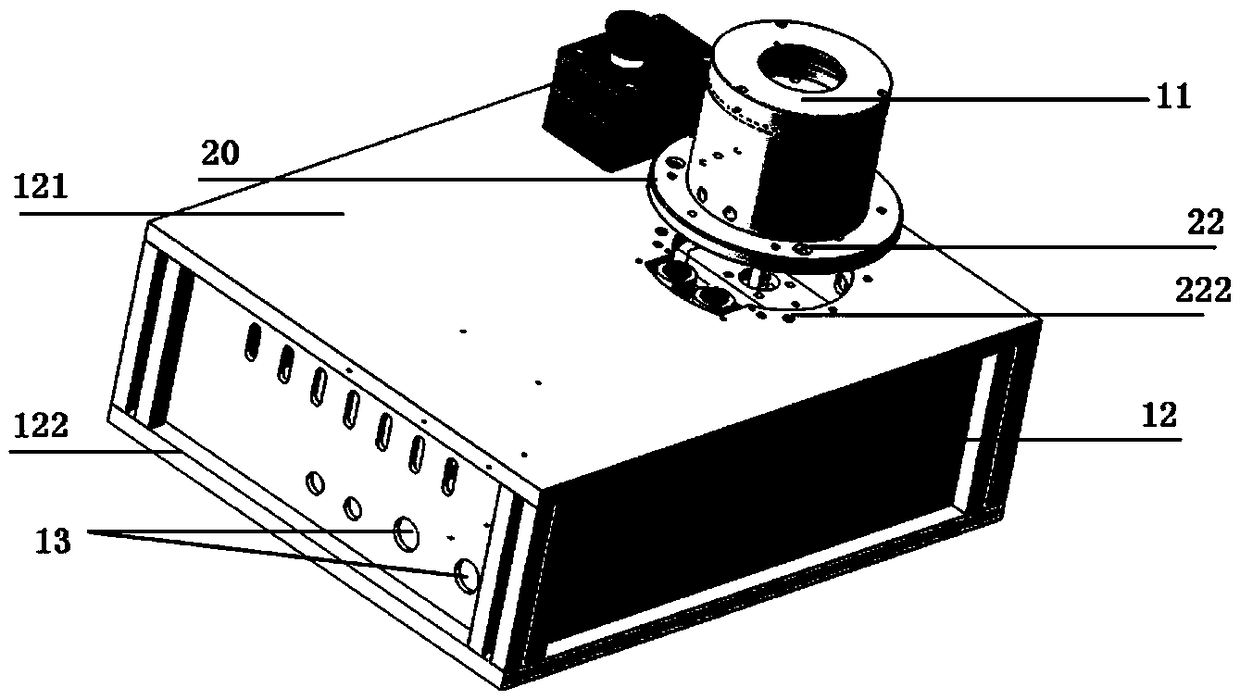

[0035] figure 1 It shows an embodiment of a radial magnetizing coil quick replacement device of the present invention, the appearance state when the magnetizing coil is positioned and connected to the magnetizing machine. figure 2 It shows the appearance state of this embodiment when the magnetizing coil is separated from the magnetizing machine for replacement.

[0036] like figure 1 and figure 2 As shown, the radial magnetizing coil quick replacement device in this embodiment has a magnetizing coil assembly 11 and a magnetizing machine table 12 .

[0037] Contain coil 40 in the magnetizing coil assembly 11 (see Figure 4 ), preferably with a coil former, and optionally embedded with temperature and / or magnetometric sensors.

[0038] In one embodiment, the case of the magnetizing machine 12 is composed of an upper cover 121 and a bottom plate 122 . The magnetizing machine 12 is provided with a circuit connection device, and preferably a cable interface 13 is provided...

Embodiment 2

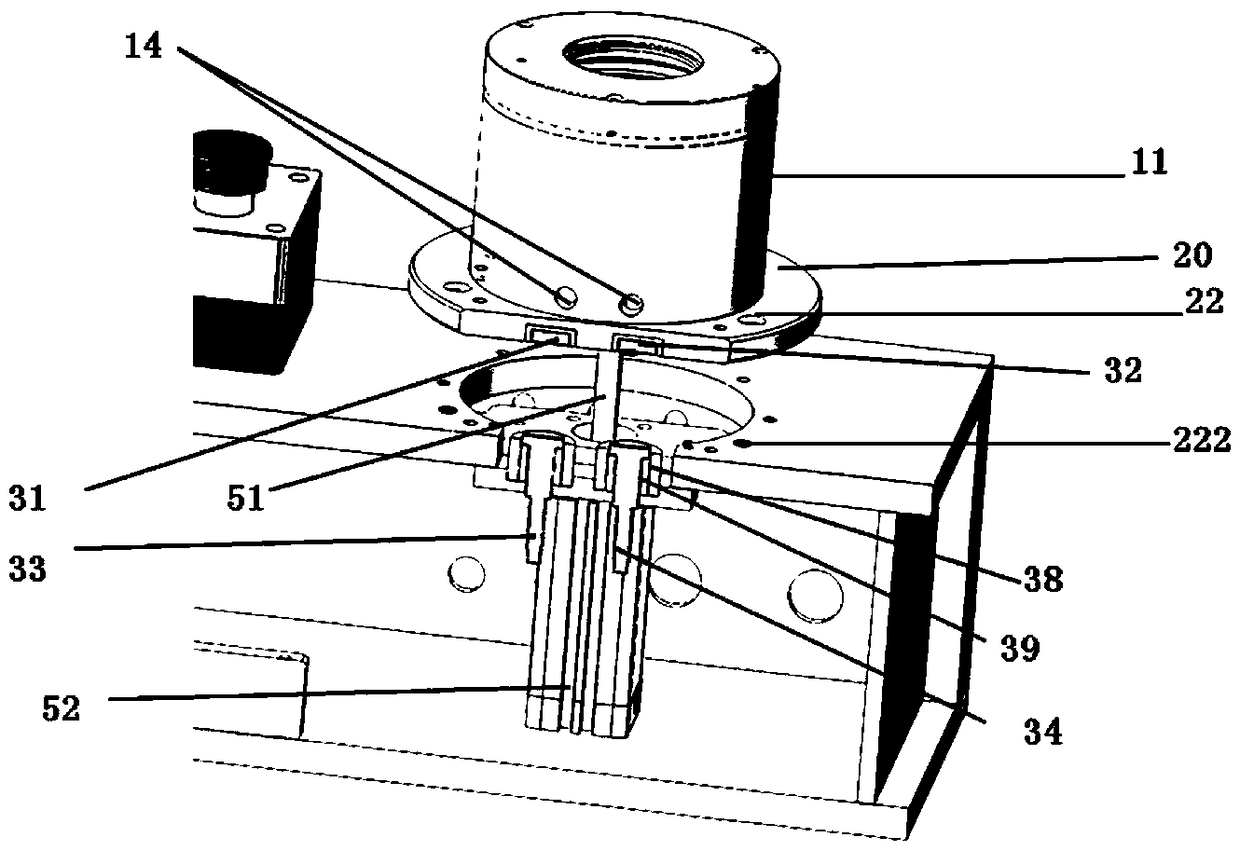

[0047] image 3 An embodiment of the electrode connection between the magnetizing coil and the magnetizing machine is given, using T-shaped electrodes and elastic gaskets. Of course, in practice, the electrode connection method that can realize the function of "when the magnetizing coil is vertically positioned and connected to the magnetizing machine, the electrical connection between the magnetizing coil and the magnetizing machine will be automatically completed" is not limited to image 3 Example of this one.

[0048] Another example is Figure 5 As shown, the electrodes 331 and 341 of the magnetizing machine 12 are I-shaped electrodes or L-shaped electrodes, and the elastic device 37 is arranged at the bottom of the electrodes 331 and 341 . The elastic device 37 is, for example, a spring.

[0049] Yet another example Image 6 As shown, the electrodes between the magnetizing coil assembly 11 and the magnetizing machine table 12 are electrically connected by means of ma...

Embodiment 3

[0051] Since the magnetizing machine of the present invention is produced in a standardized manner and does not need to be replaced frequently, more functions can be conveniently added to make a machine with richer functions and more convenient use.

[0052] Such as adding pneumatic components. like image 3 and Figure 4 As shown in , an embodiment of the present invention is provided with pneumatic components, including a pneumatic column 51, a cylinder 52, and the cylinder is connected with an air pump (not shown in the figure) for inflating and pumping air. For example, when a button is pressed or the magnetizing task is completed, the system will automatically inflate the cylinder 52 with the air pump, the air pressure in the cylinder 52 will rise, and the pneumatic column 51 will be lifted up, and the pneumatic column 51 will rise with the magnetized product, which is convenient Magnetizers take out magnetized products. Similarly, when another button is pressed, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com