Connector with end-voltage shielding spring sheet structure

A connector, end-pressing technology, applied in the direction of connection, parts of the connection device, contact parts, etc., to achieve the effect of simple mold, reduced production cost, and good shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical scheme of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

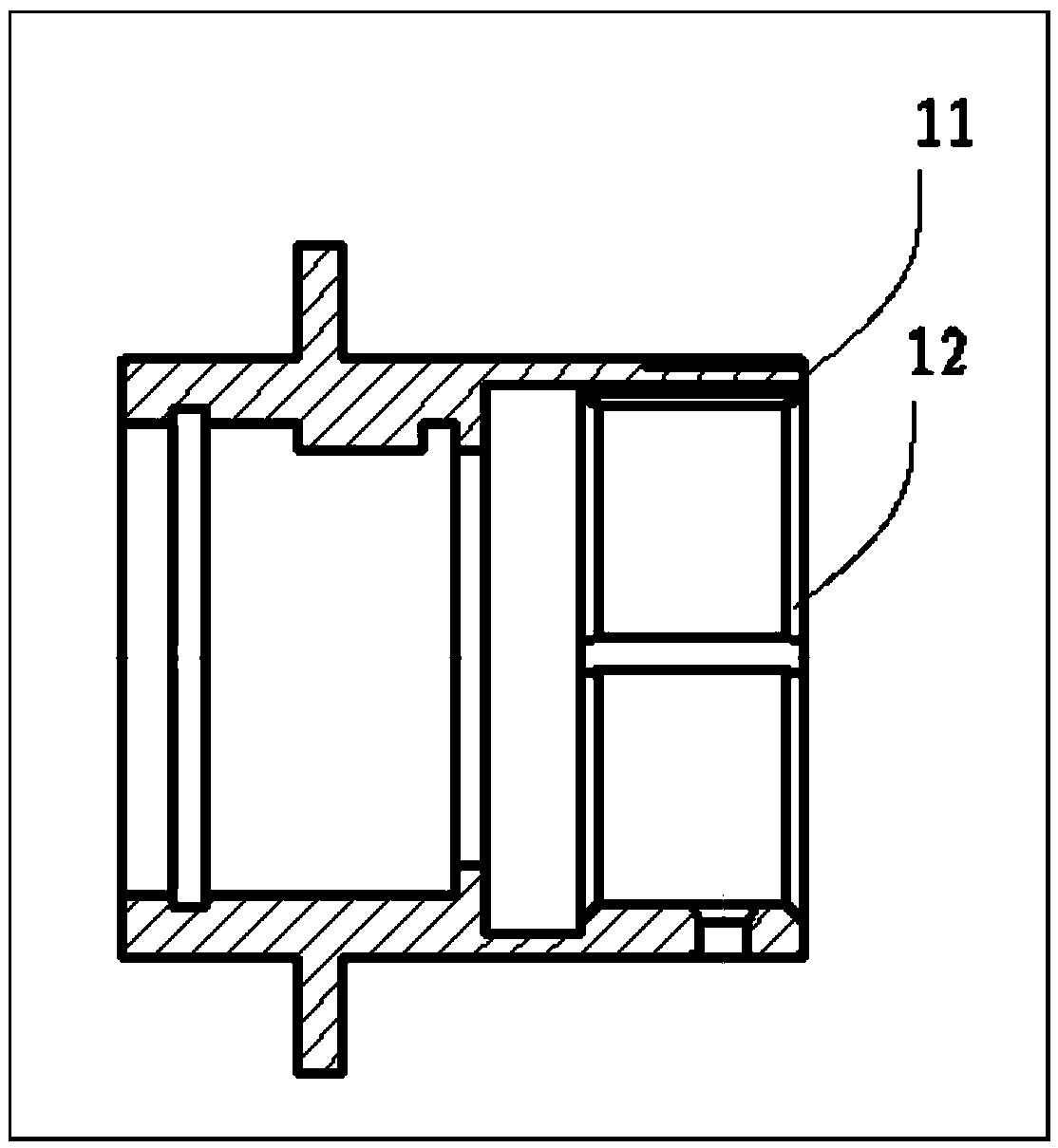

[0028] The invention discloses a connector with an end-pressure shielding reed, which can realize the installation in a tiny space of 2mm and significantly reduce the axial dimension of the connector; the structure of the end-pressure shielding reed is simpler and can be purchased by a set of less than 10,000 yuan It is produced by simple stamping die with lower cost; after stamping and forming, it can be directly assembled and used after surface treatment without other processing procedures such as resistance welding.

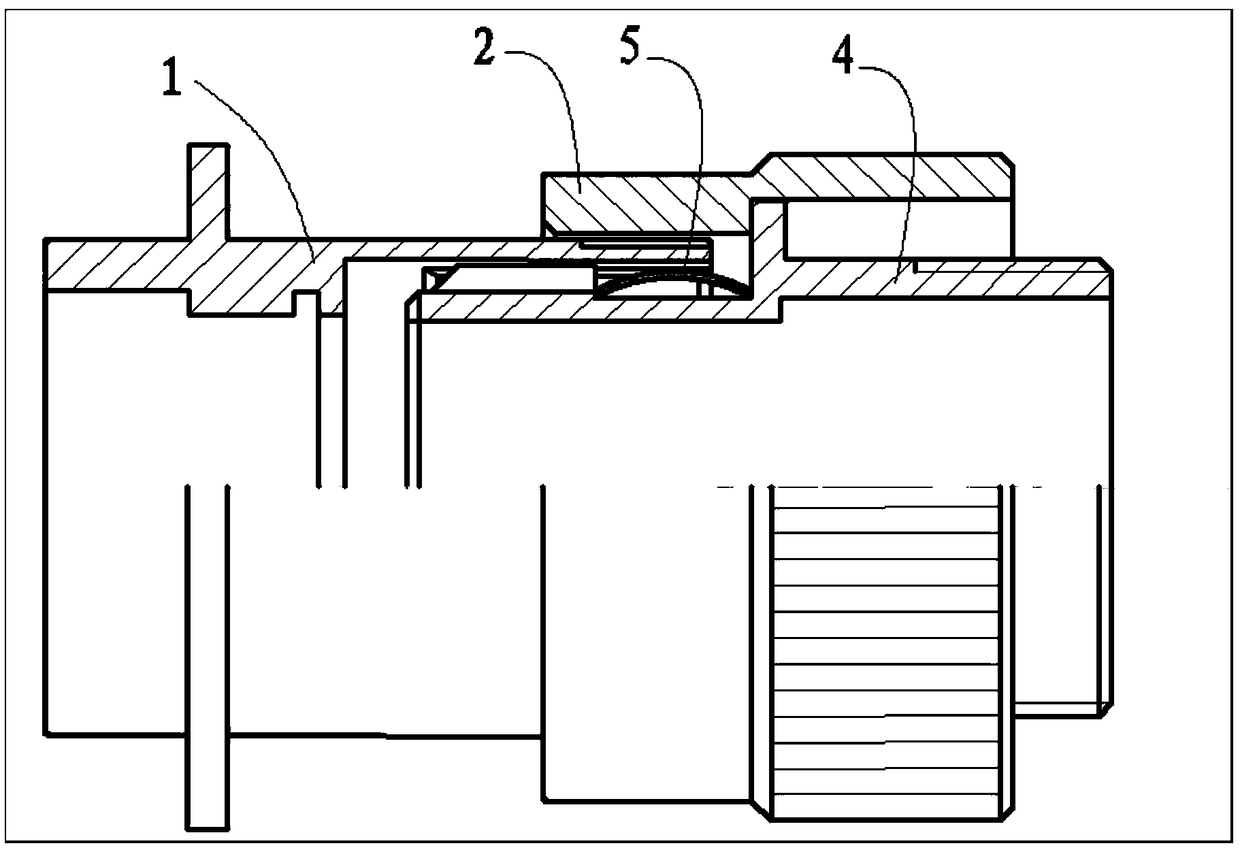

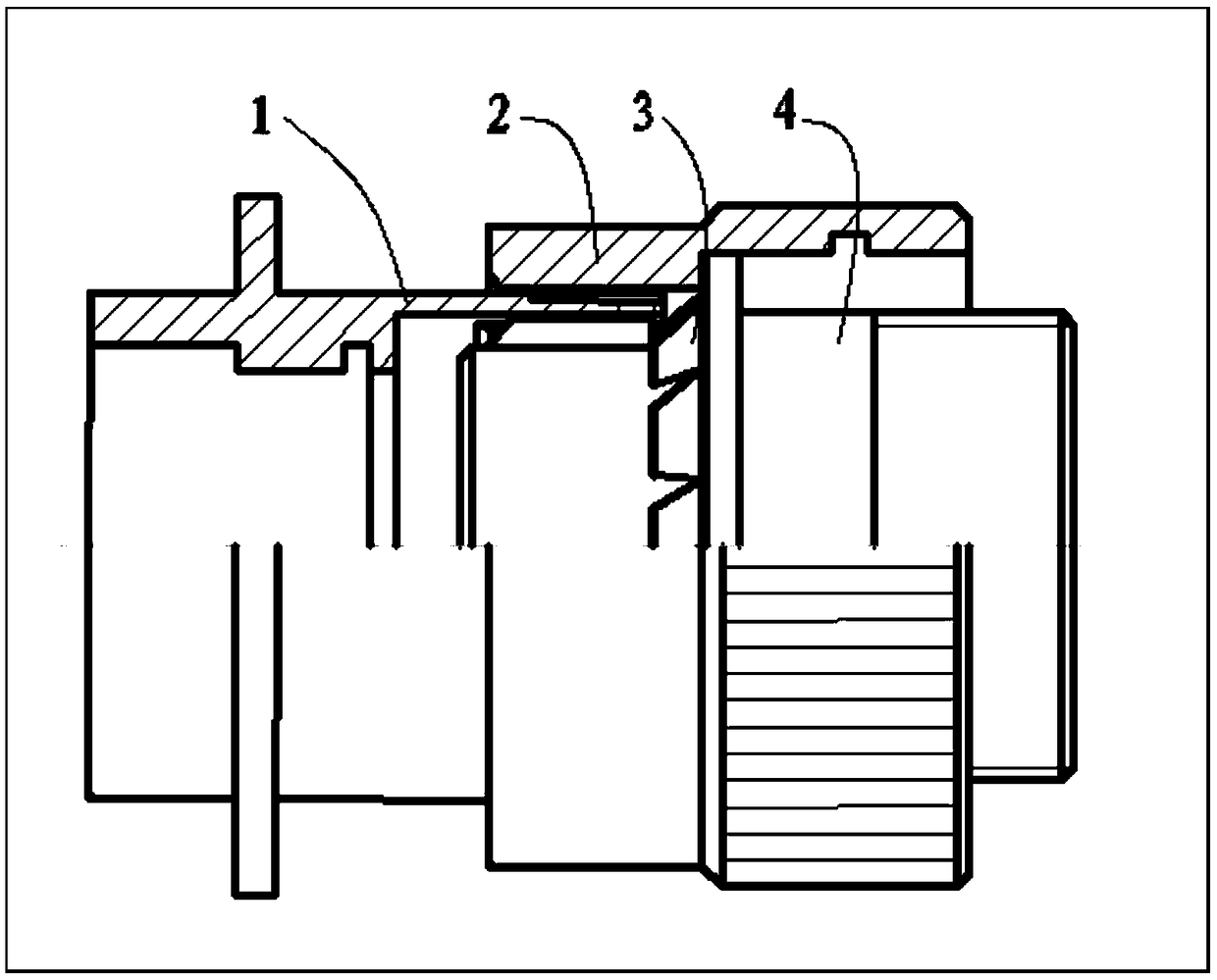

[0029] Specifically, in an exemplary embodiment, as figure 2 As shown, the connector with end-pressure shielding reed in this embodiment includes a seat housing 1 , a header housing 4 , a connection cap 2 and an end-pressure shielding reed 3 .

[0030] Wherein, the connecting cap 2 is sleeved on the head she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com