Shaft hole machining method for walking balance beam of crane

A processing method and balance beam technology, applied in metal processing equipment, manufacturing tools, boring/drilling, etc., can solve problems such as high processing costs, difficult shaft hole processing, and scarce processing equipment resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0122] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

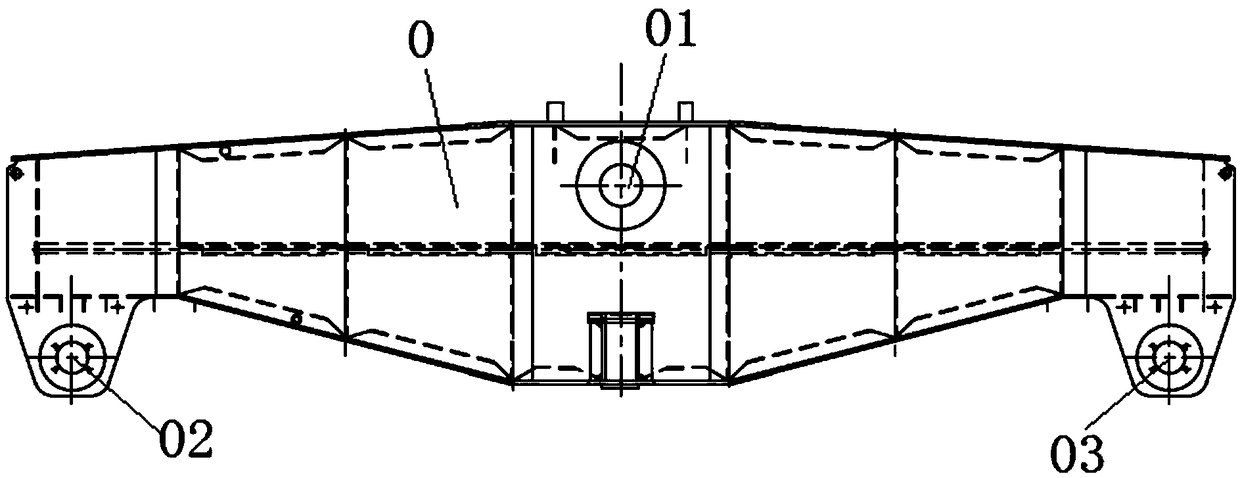

[0123] figure 1 Shown is the walking balance beam 0 that needs to be processed with three parallel shaft holes. The shaft holes that need to be processed are the middle shaft hole 01, the left shaft hole 02, and the right shaft hole 03.

[0124] A method for machining an axle hole of a traveling balance beam of a crane, comprising the following steps:

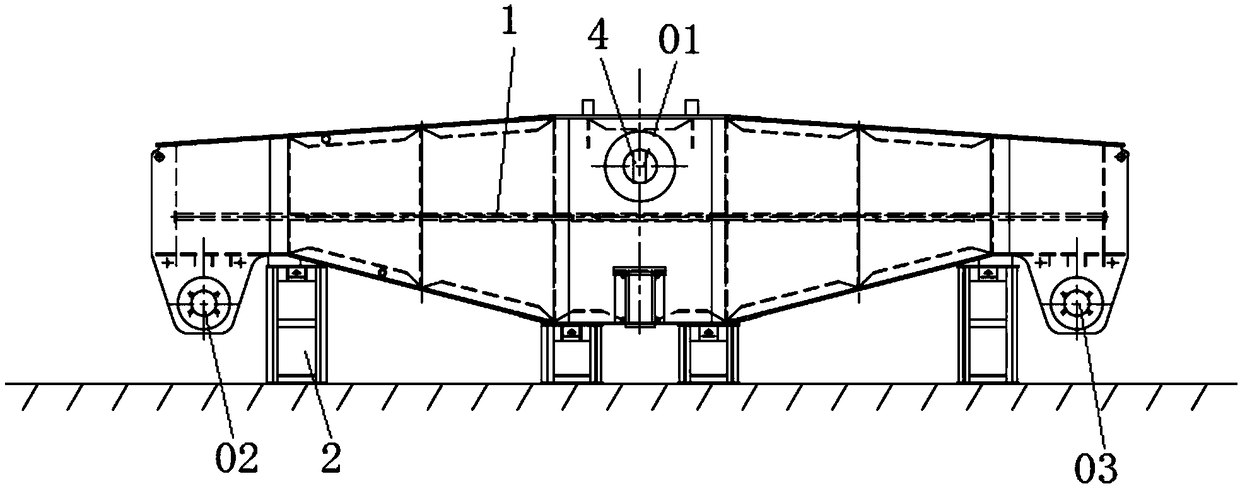

[0125] Step (1): If figure 2 As shown, use the tooling stool 2 to place the walking balance beam 0 on the ground, adjust the level of the walking balance beam 0 based on the horizontal waistline 1 of the walking balance beam, and fix the walking balance beam 0 after adjustment;

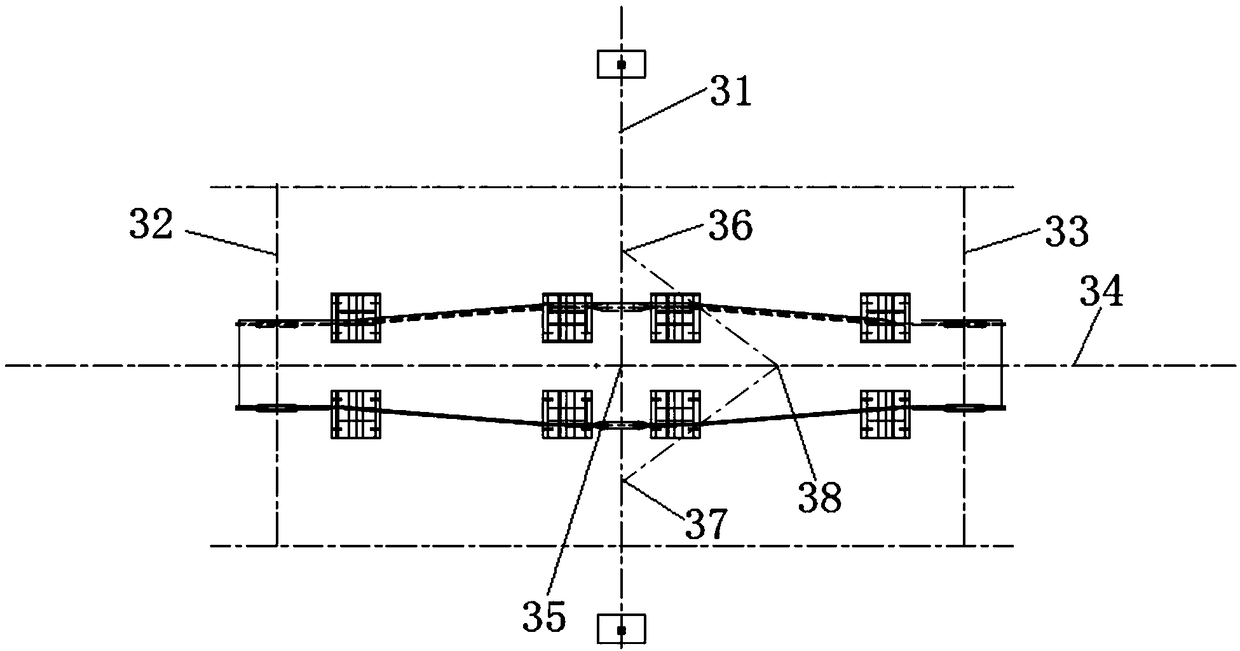

[0126] Step (2): If image 3 As shown, draw the sample line 31 of the middle shaft hole center line, the sample line 32 of the left shaft hole center line, the sample line 33 of the right shaft hole center line and the sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com