Bobbin double-clamping-jaw mechanism

A technology of I-shaped wheel and double jaws, applied in the direction of chuck, manipulator, manufacturing tool, etc., can solve the problems of many round-trip processes of the mechanism, affecting efficiency, emptying, clamping deviation, clamping leakage, etc., and achieves energy saving and high efficiency in the process. Simple, accurate and reliable moving action, and the effect of meeting the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

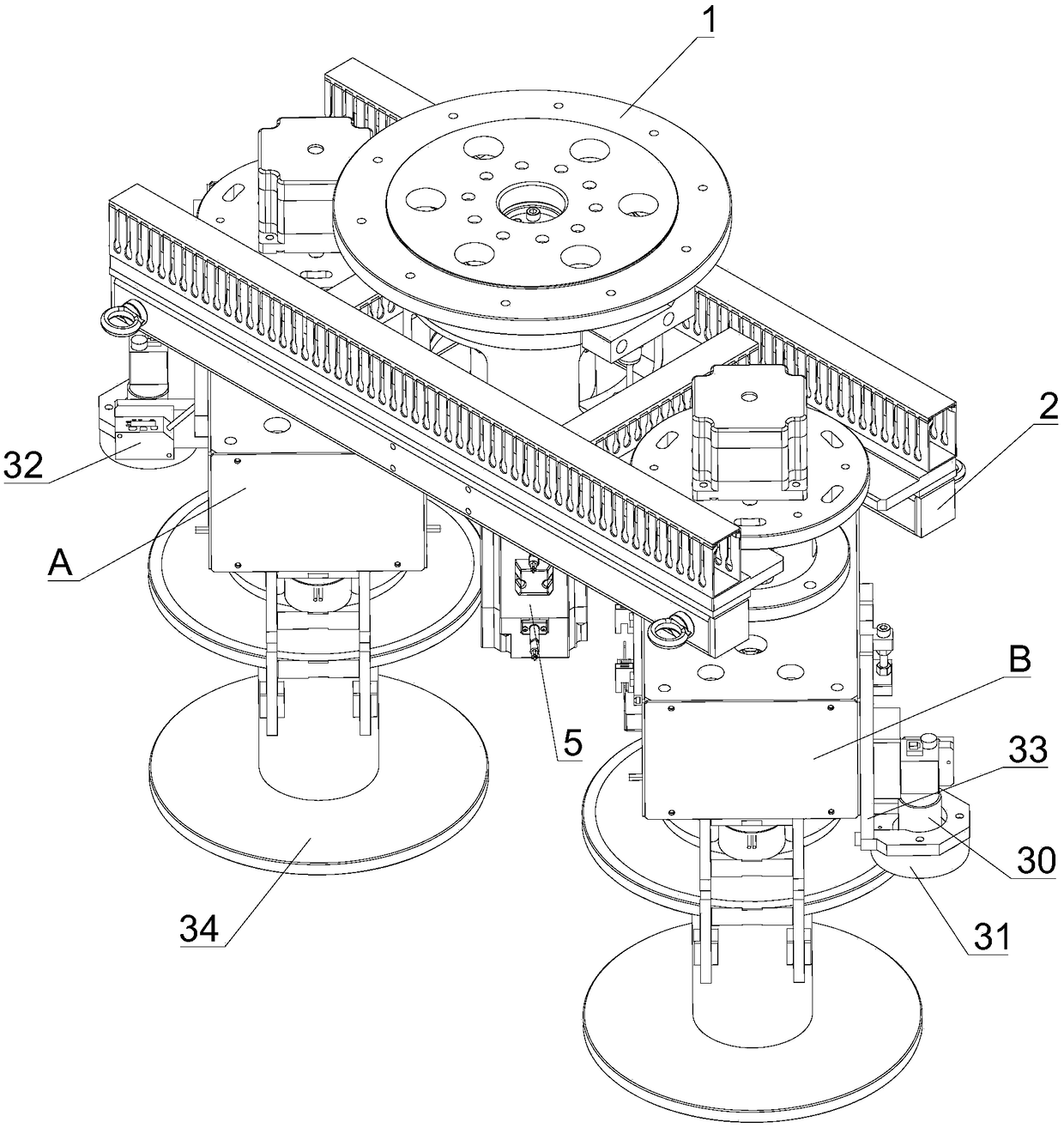

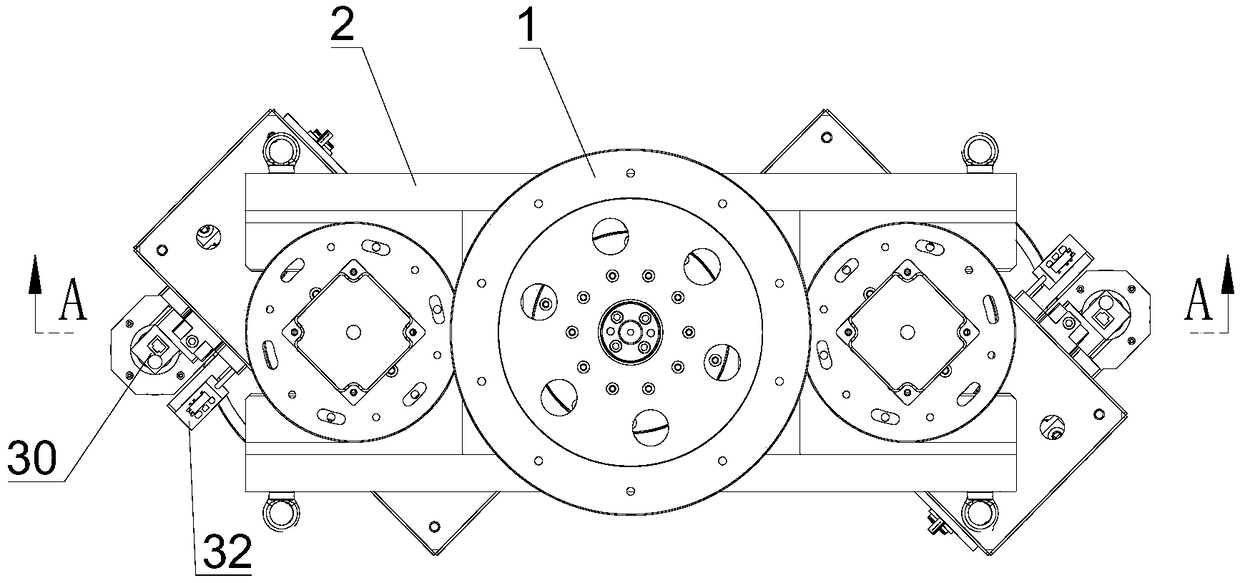

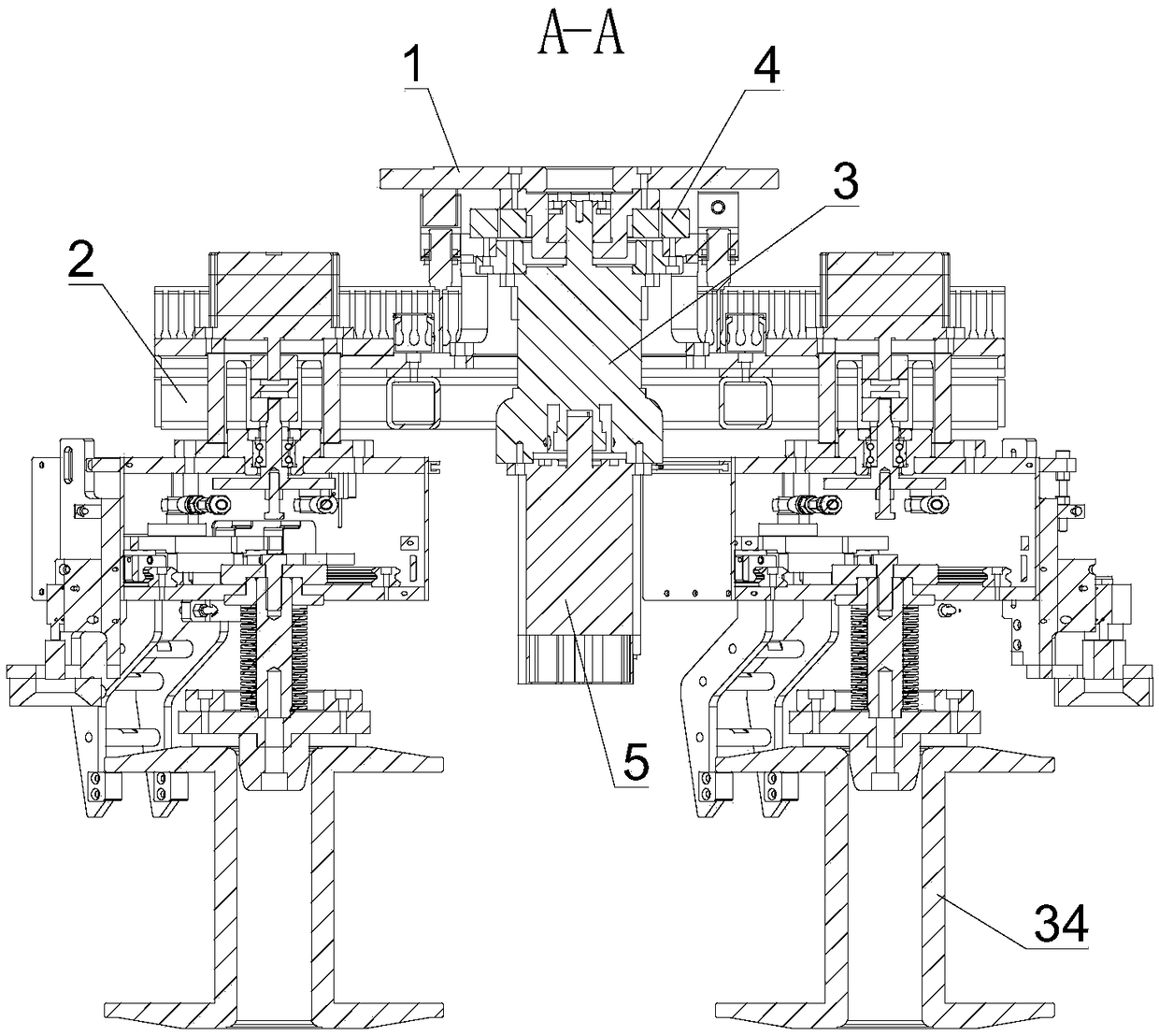

[0030] see Figures 1 to 8 As shown, this embodiment provides an I-wheel double-claw mechanism to provide an automatic handling solution for the steel cord I-wheel. The double-claw mechanism is used for assembly on the truss manipulator and mainly includes a connecting flange 1 , mounting base 2, jaw assembly and visual positioning assembly.

[0031] Wherein, the connecting flange 1 is used for fixed connection with the truss manipulator.

[0032] The mounting base 2 is provided with a rotating assembly, the rotating assembly includes a reducer 3, a cross roller bearing 4 and a rotating drive motor 5, the output shaft of the reducer 3 is fixedly connected to the connecting flange 1, and the rotating drive motor 5 is connected to the reducer 3 The input end is connected, and the cross roller bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com