Rubber belt shearing device and method

A technology of shearing device and rubber belt, which is applied in metal processing and other directions, can solve the problems of unfixable rubber belt, low cutting precision, and low production efficiency, and achieve the effects of reducing labor costs, improving work efficiency, and operating safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

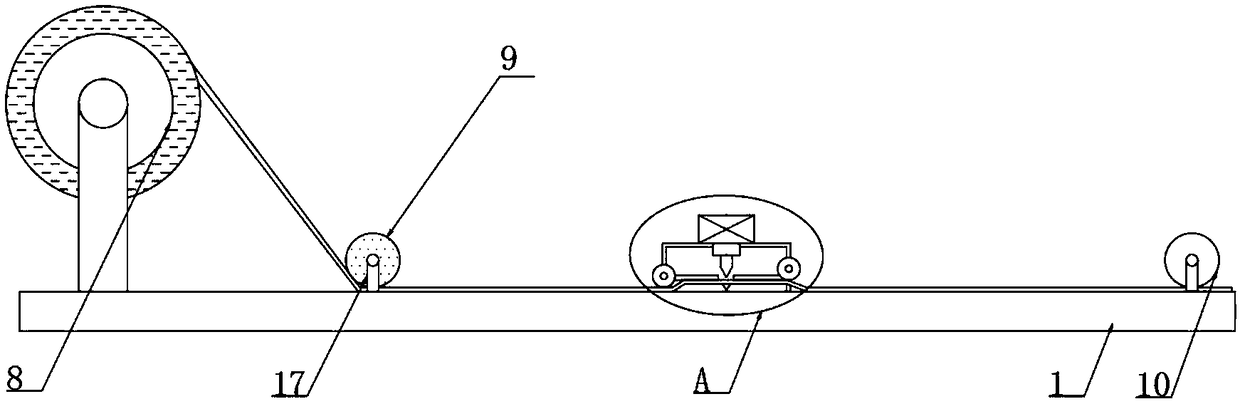

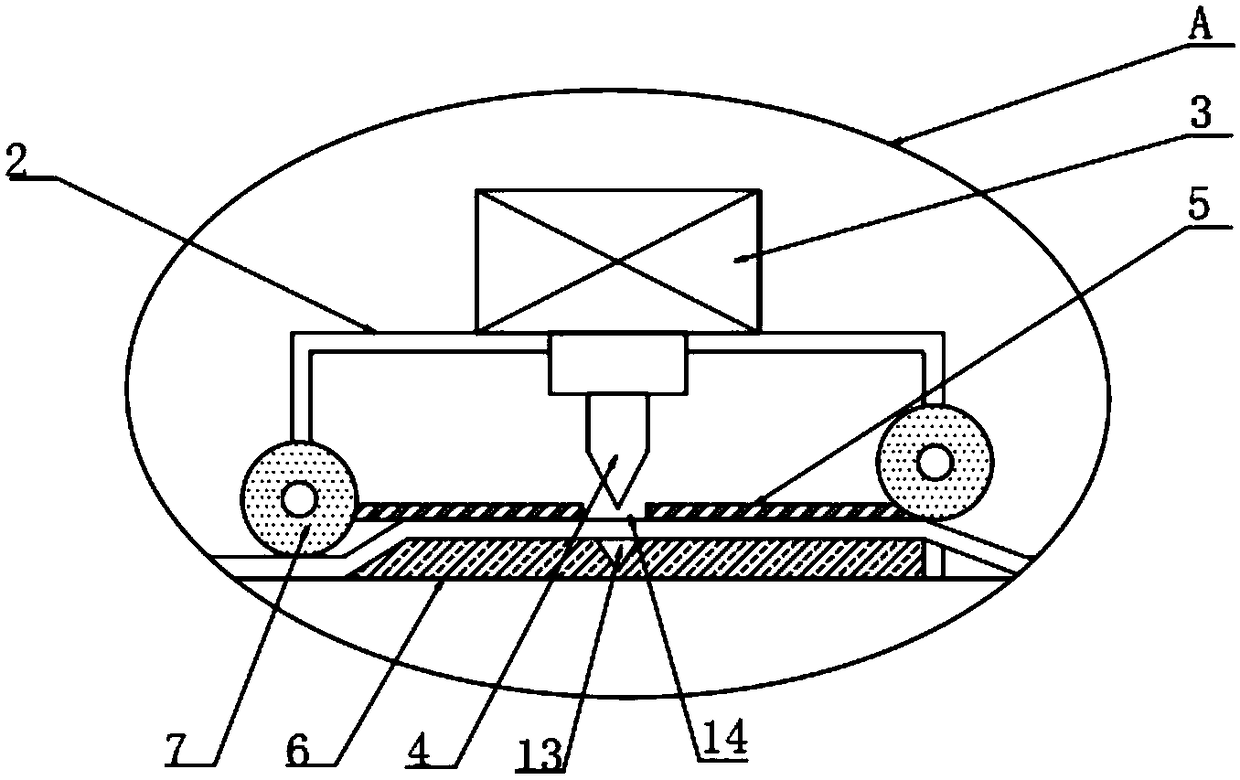

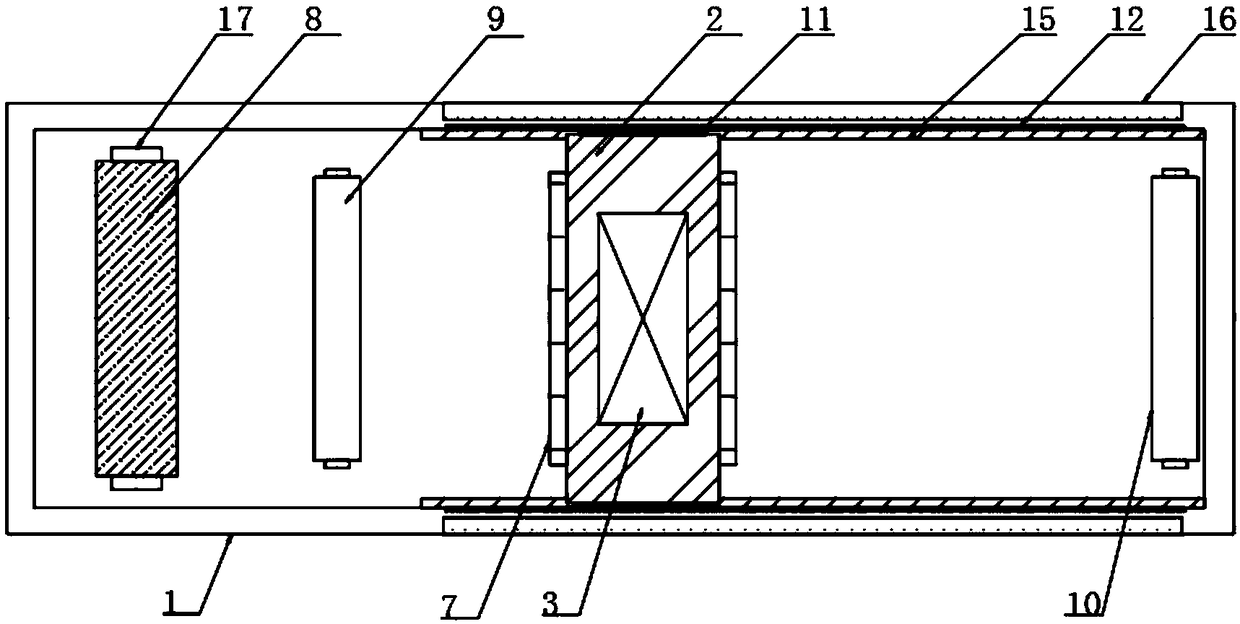

[0025] The present invention provides Figure 1-3 The rubber belt shearing device shown includes a workbench 1, a fixed block 2 is arranged on the top of the workbench 1, an electric push rod 3 is arranged on the top of the fixed block 2, and an output shaft of the electric push rod 3 is arranged There is a cutter 4, the bottom of the cutter 4 is provided with a compression block 5, which is convenient for pressing and fixing the rubber band, the bottom of the fixed block 2 is provided with a backing plate 6, and the fixed block 2 has an inlet and an outlet Each is provided with a first electric roller 7, a roller 8 is arranged on one side of the fixed block 2, a second electric roller 9 is arranged between the roller 8 and the fixed block 2, and the other side of the fixed block 2 is arranged There is a third electric roller 10 to facilitate the movement of the rubber belt.

[0026] Further, in the above technical solution, the fixing block 2 is provided with a clamping block 11...

Embodiment 2

[0035] A rubber belt cutting method, including the rubber belt cutting device, further comprises the following steps:

[0036] S1: The rubber band can enter the inside of the fixed block 2;

[0037] S2: Both the inlet and outlet of the fixed block 2 are provided with a first electric roller 7 to push the rubber belt;

[0038] S3: The electric push rod 3 is fixed on the top of the fixed block 2, and the output shaft of the electric push rod 3 penetrates the fixed block 2;

[0039] S4: The first electric roller 7 is opened to tighten the rubber belt;

[0040] S5: The cutter 4 cuts the rubber band through the slot 14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com