Gathering connection container

A container and peripheral piece technology, applied in the field of sheet metal containers, can solve the problems of poor effect, heavy grinding workload, and easy accumulation of errors, etc., and achieve the effect of good appearance quality, reduced workload, and stable shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

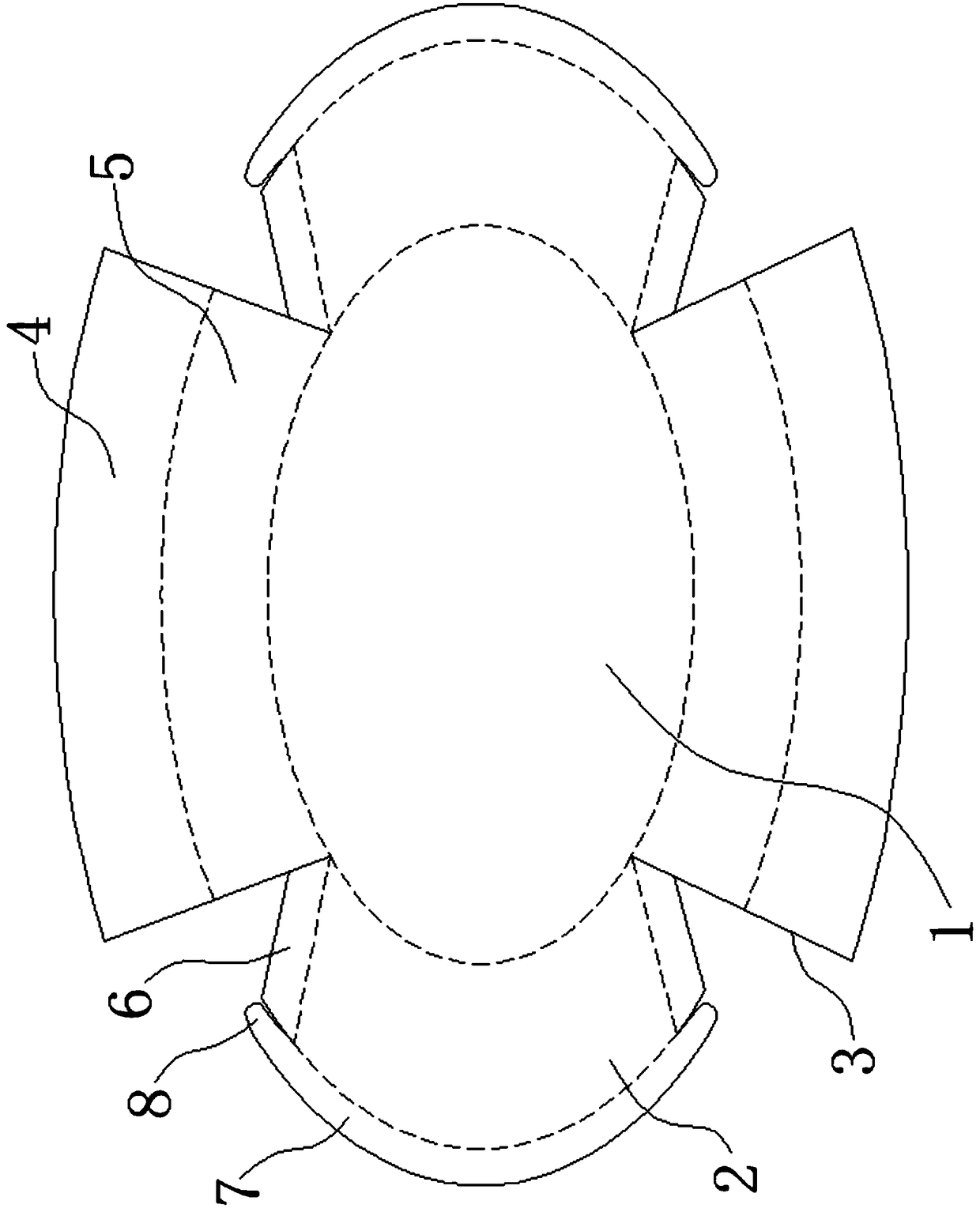

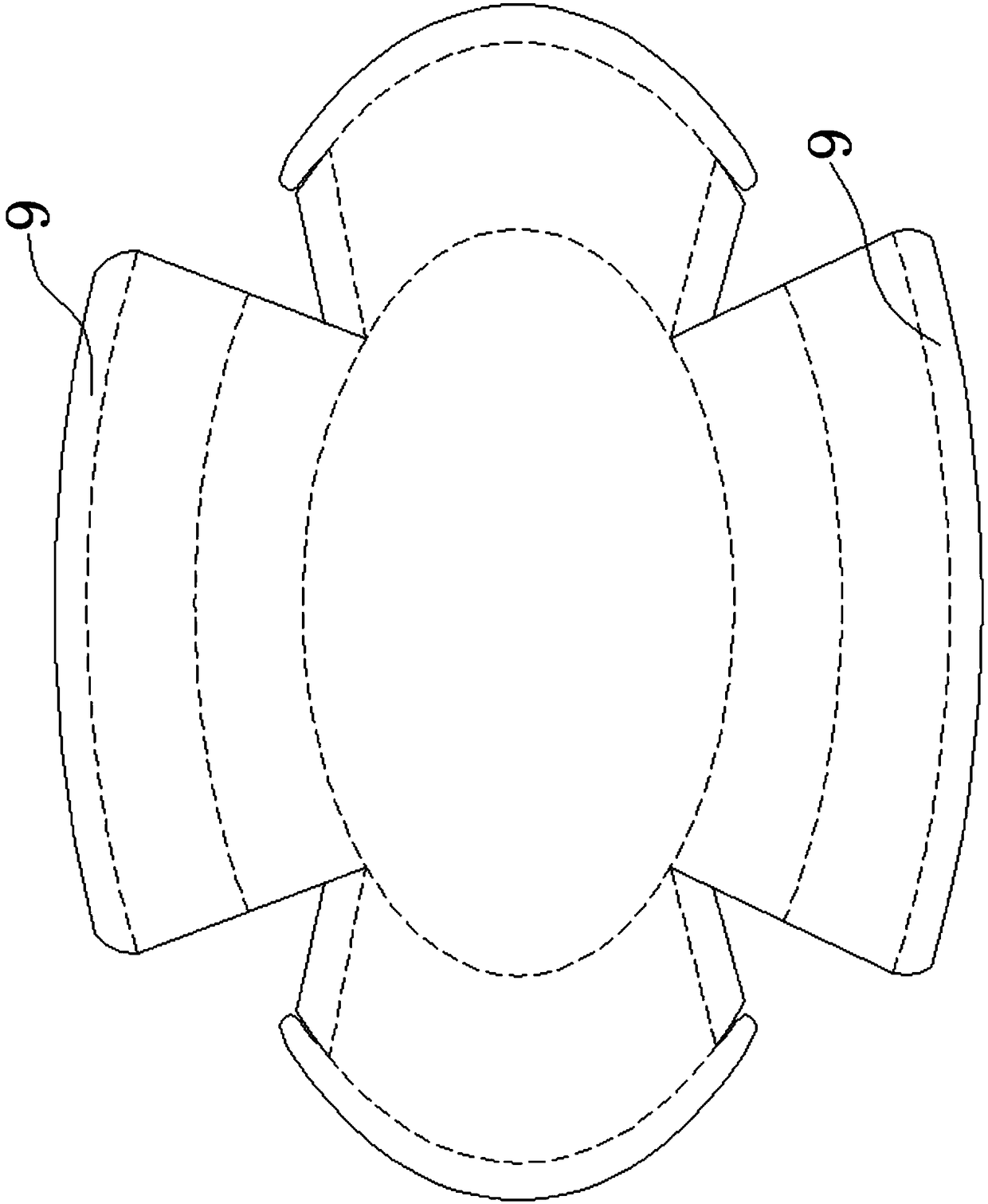

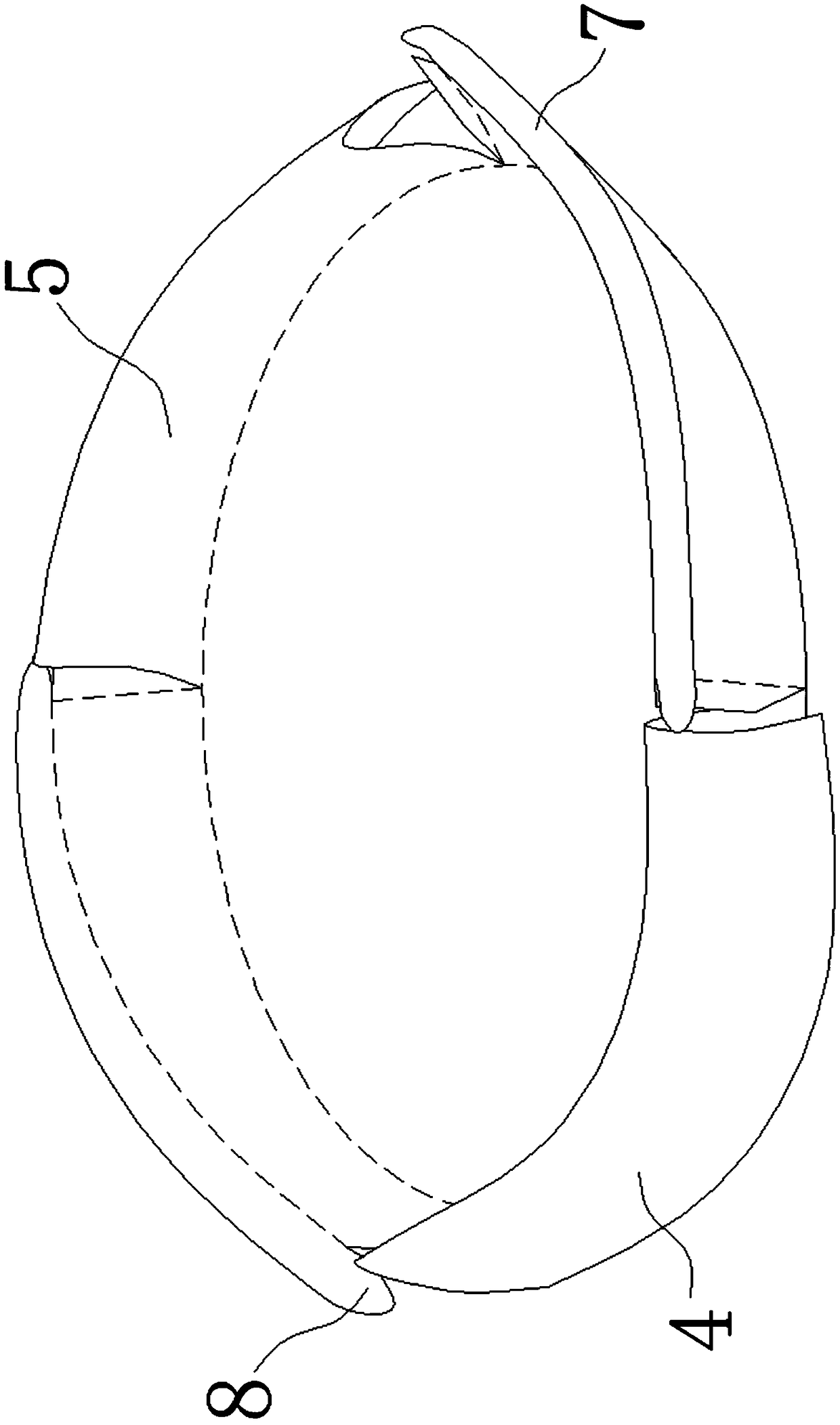

[0033] In order to achieve the purpose of the present invention, a closed connection container includes: a bottom 1, which is in the shape of a disc; It includes an integrated inner perimeter piece 5 and outer perimeter piece 4; side upright piece 2, which is connected to the bottom 1 and is arranged in a circular array along the center of the bottom 1; The circumferential ends of 1 are equipped with tongues 6, the inner peripheral sheet 5 and the peripheral sheet 4 are folded and overlapped, the tongue 6 is inserted into the gap between the inner peripheral sheet 5 and the peripheral sheet 4, and the side standing sheet 2 is at the end away from the bottom 1 Be provided with flanging 7, flanging 7 is provided with convex tongue 8 along the circumferential two ends of the bottom, and convex tongue 8 is bonded with one side away from inner peripheral sheet 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com