Half-and-half precast gallery structure and gallery construction method

A construction method and corridor technology, applied in infrastructure engineering, sustainable manufacturing/processing, water conservancy engineering, etc., can solve problems such as long construction period, continuous increase in impact, and increased construction cost, and achieve good overall stability and standardization The effect of short construction and construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the drawings:

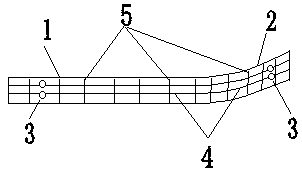

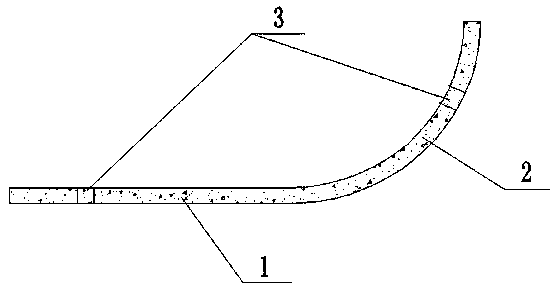

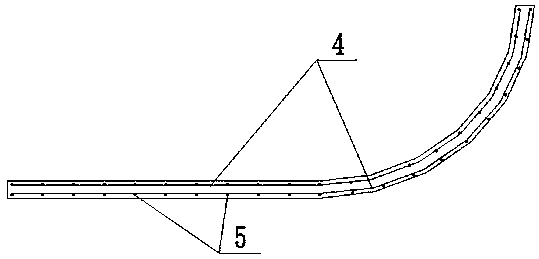

[0029] Such as Figure 1-3 As shown, the half-and-half prefabricated corridor structure is composed of a pair of symmetrical split bodies assembled, and the symmetrical split bodies include an integrally connected straight wall section 1 and a top arch section 2, and the straight wall section 1 and the top arch section 2 extend surfaces Two layers of steel mesh are arranged, and the steel mesh is composed of longitudinal steel bars 4 and transverse steel wires 5 laid perpendicular to each other, and four lifting holes 3 are provided on the symmetrical split body.

[0030] The four lifting holes 3 are respectively arranged in pairs at the outer ends of the straight wall section 1 or the top arch section 2.

[0031] The symmetrical split body is prefabricated separately. The prefabricated block assembly length of the symmetrical split body is 1m and the thickness is 0.12m. The constructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com