Reinforcing steel bar sleeve-free type soil anchor rod anchor head

A casing type, steel bar technology, applied in construction, sheet pile wall, infrastructure engineering and other directions, can solve the problems of high cost and low pullout resistance, and achieve the effect of small aperture and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

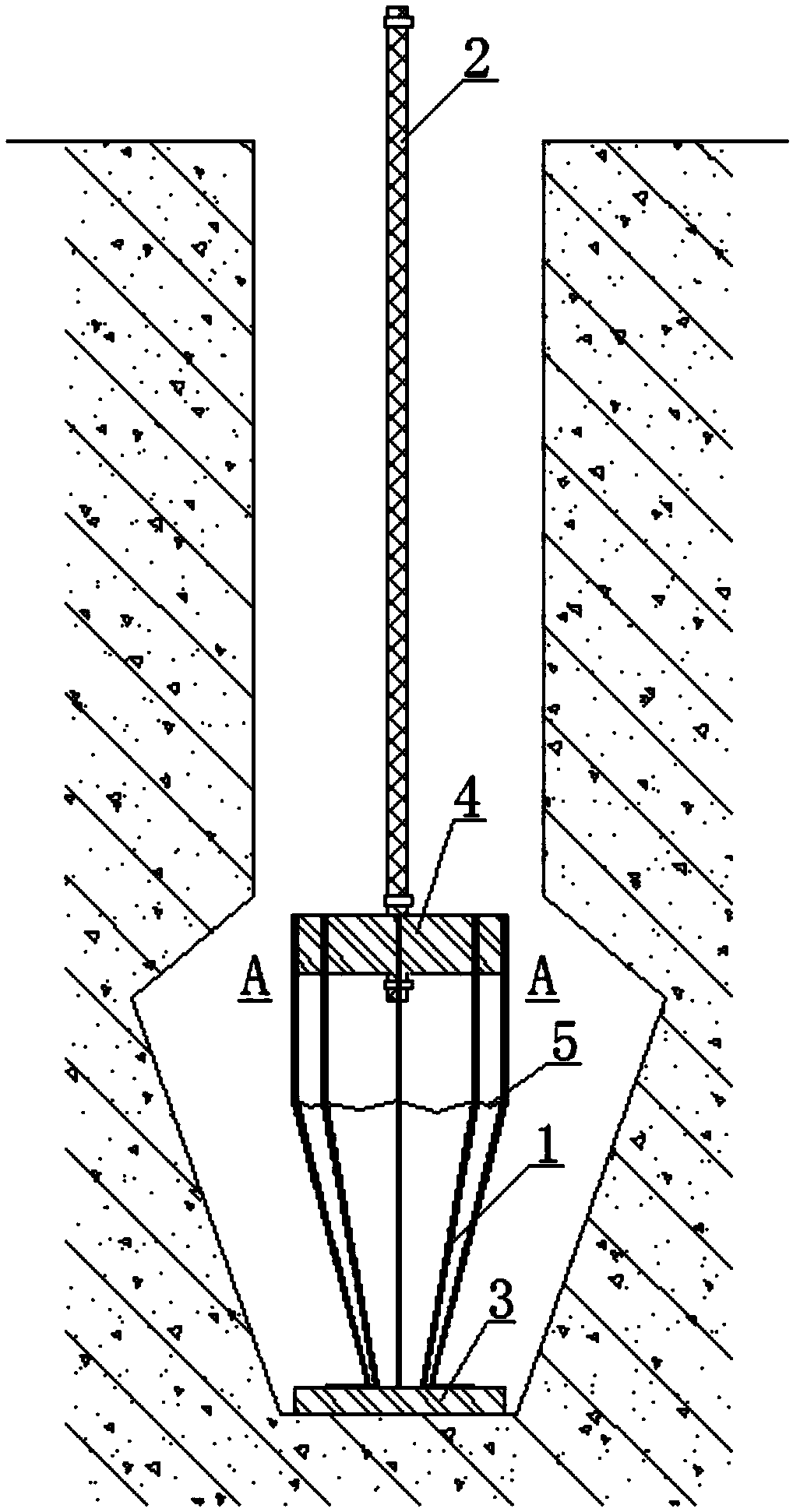

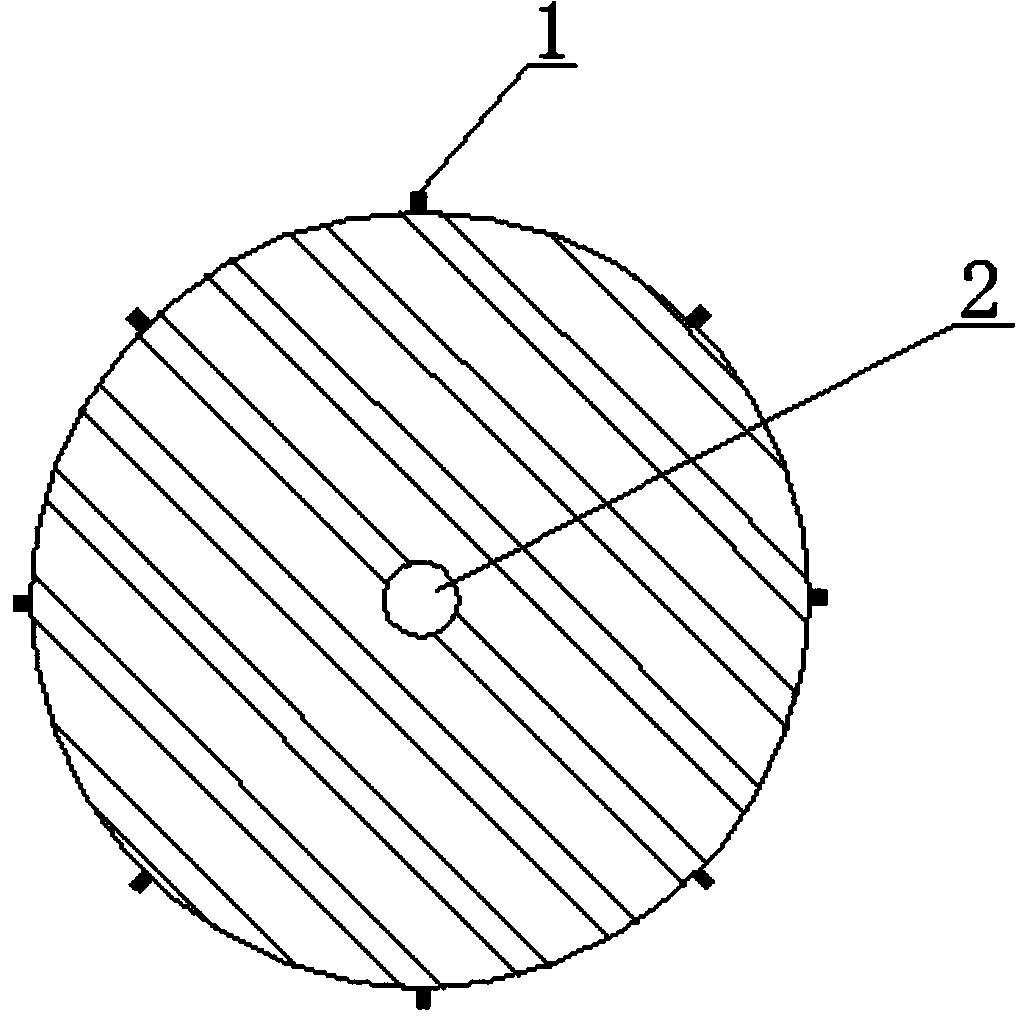

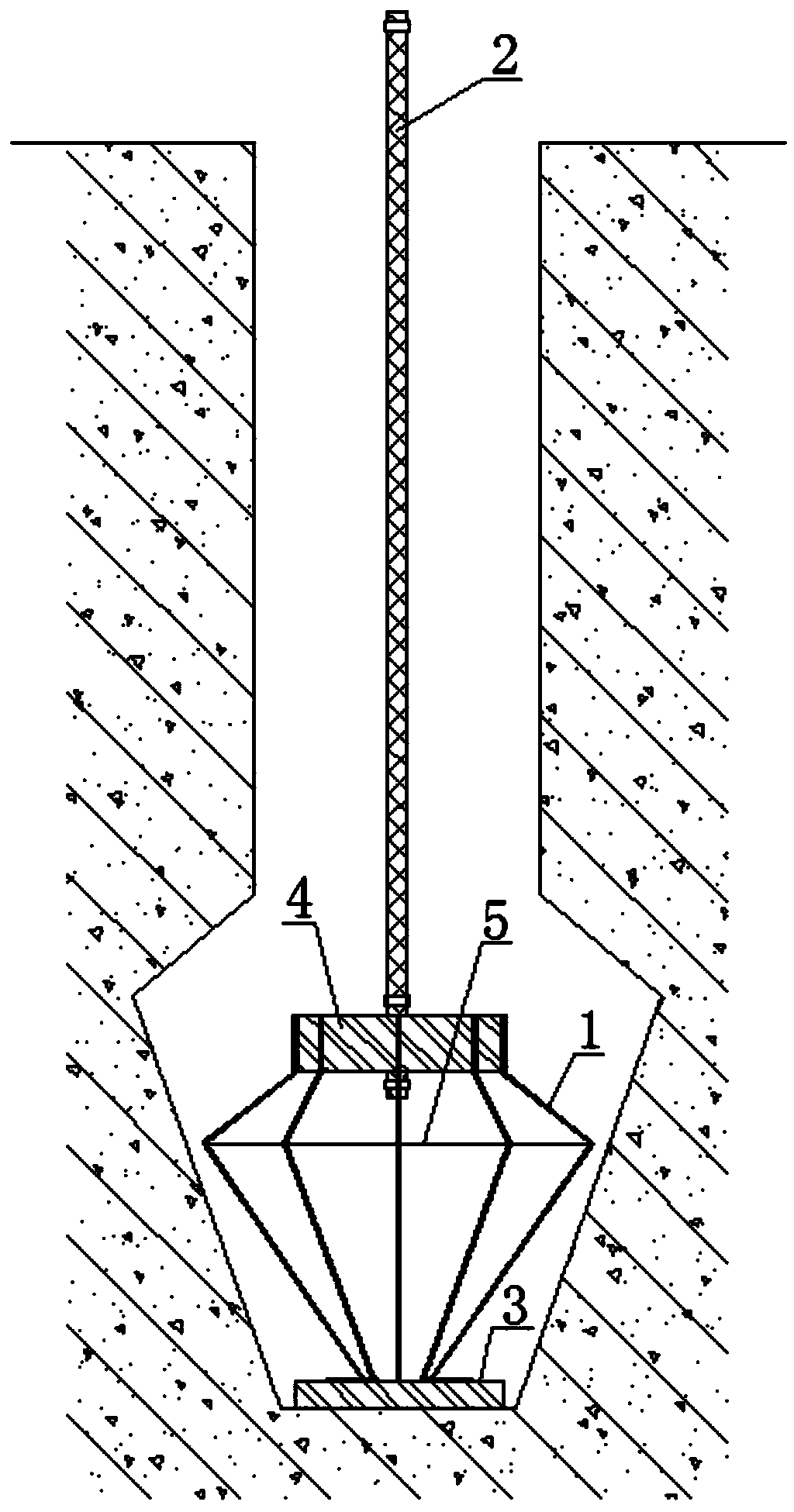

[0016] see Figure 1 to Figure 2 , a steel bar casing-free soil anchor head, including a barrel-shaped anchor wall surrounded by multiple groups of steel bars 1 equidistantly arranged at intervals, where the multiple groups are three groups or more; the described A base plate 3 is provided at the bottom of the anchor wall, and a top plate 4 is provided at the top of the anchor wall. The upper part of the anchor rod wall is a straight section, and the lower part of the anchor rod wall is bent into a cone. The middle part of the top plate 4 is provided with a finish-rolled rebar 2 , and there is a nut on the top and bottom of the top plate 4 , and two nuts and the top plate 4 pass through the bottom of the finish-rolled rebar 2 .

[0017] see Figure 1 to Figure 2 , the ratio of the upper straight section of the anchor wall to the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com