Height-adjustable weaving machine tool suitable for flow line production

A streamlined and adjustable technology, applied in the direction of supporting machines, mechanical equipment, machine tables/supports, etc., can solve the problems of wasting time and labor costs, limited maintenance space, and reducing user work efficiency, so as to improve work efficiency, The effect of reducing difficulty and facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

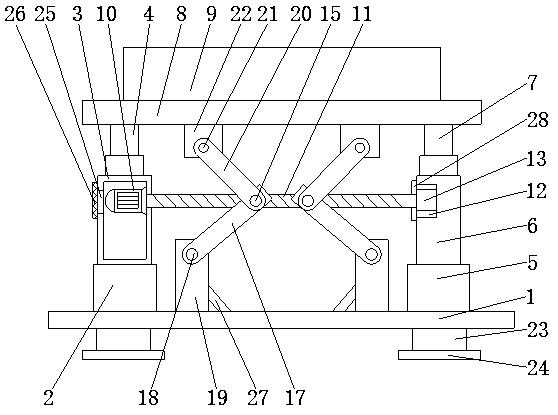

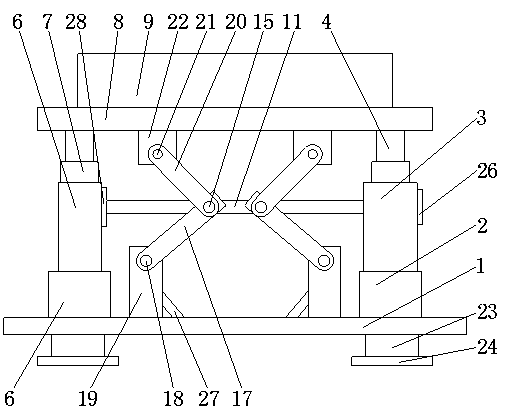

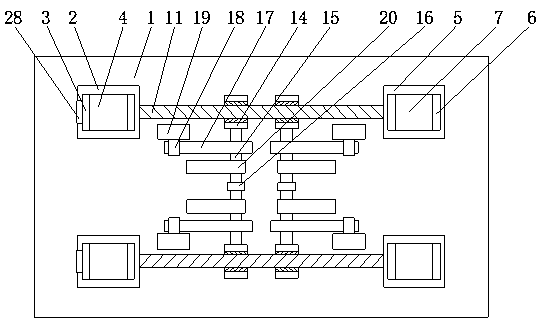

[0018] First implementation: see Figure 1-3 , a height-adjustable textile machine tool suitable for assembly line operations, comprising a bottom plate 1, two first fixed seats 2 are fixedly connected to the left side of the top of the bottom plate 1, and the top of the first fixed seat 2 is fixedly connected to an organic casing 3, the casing The top of 3 is fixedly connected with the first telescopic rod 4, the right side of the bottom plate 1 top is fixedly connected with the second fixed seat 5 compatible with the first fixed seat 2, and the top of the second fixed seat 5 is fixedly connected with the support seat 6 , the top of the support seat 6 is fixedly connected with the second telescopic rod 7, the top of the first telescopic rod 4 and the second telescopic rod 7 are fixedly connected through the bottom of the workbench 8, the top of the workbench 8 is provided with a machine tool body 9, a bottom plate 1 The four corners of the bottom are all fixedly connected wit...

no. 2 approach

[0021] The second embodiment: as shown in claim 1, a textile machine tool suitable for assembly line operations with adjustable height includes a base plate 1, and the left side of the top of the base plate 1 is fixedly connected with two first fixed seats 2, the The top in the first fixed seat 2 is fixedly connected with the organic casing 3, the top of the casing 3 is fixedly connected with the first telescopic rod 4, and the right side of the top of the bottom plate 1 is fixedly connected with the two first fixed rods. Two second fixed seats 5 that are compatible with the seat 2, the top of the second fixed seat 5 is fixedly connected with a support seat 6, and the top of the support seat 6 is fixedly connected with a second telescopic rod 7, the first The tops of the telescopic rod 4 and the second telescopic rod 7 are hingedly connected to the bottom of the workbench 8, the top of the workbench 8 is provided with a machine tool main body 9, and the right side of the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com