Real-time monitoring method for three-dimensional structure of disk type mirror surface

A three-dimensional structure and real-time monitoring technology, applied in image data processing, 3D modeling, instruments, etc., can solve the problems of inconvenient installation and slow speed of measurement hardware, and achieve manpower and time saving, good continuity, and fast and effective process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with accompanying drawing, the present invention will be further described

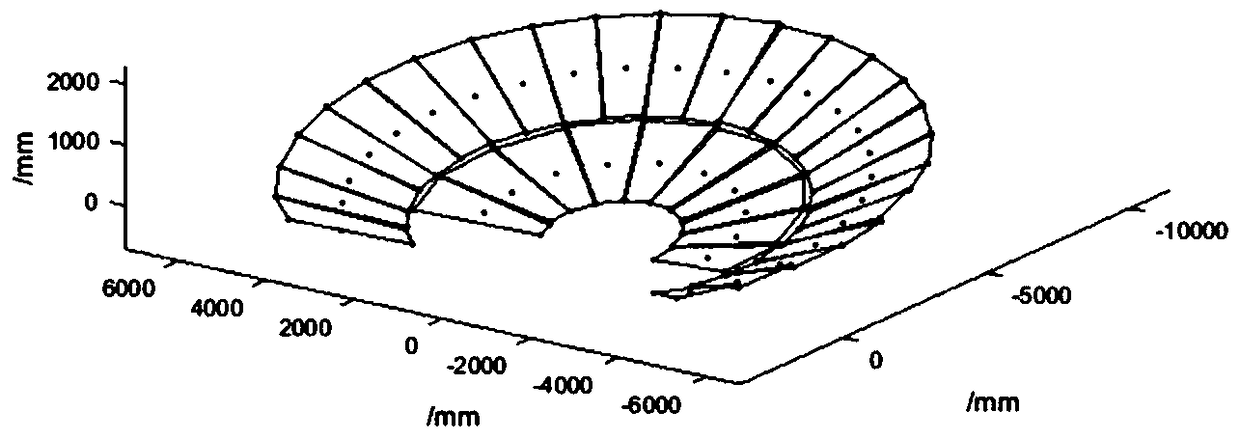

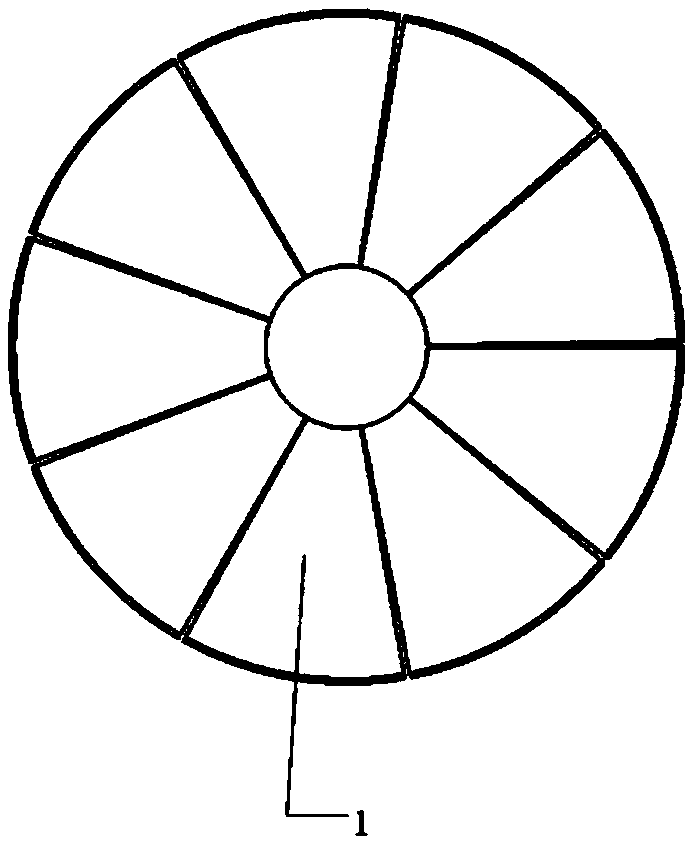

[0051] The processing object of this embodiment is as figure 1 as shown, figure 1 It is a schematic diagram of a typical butterfly mirror.

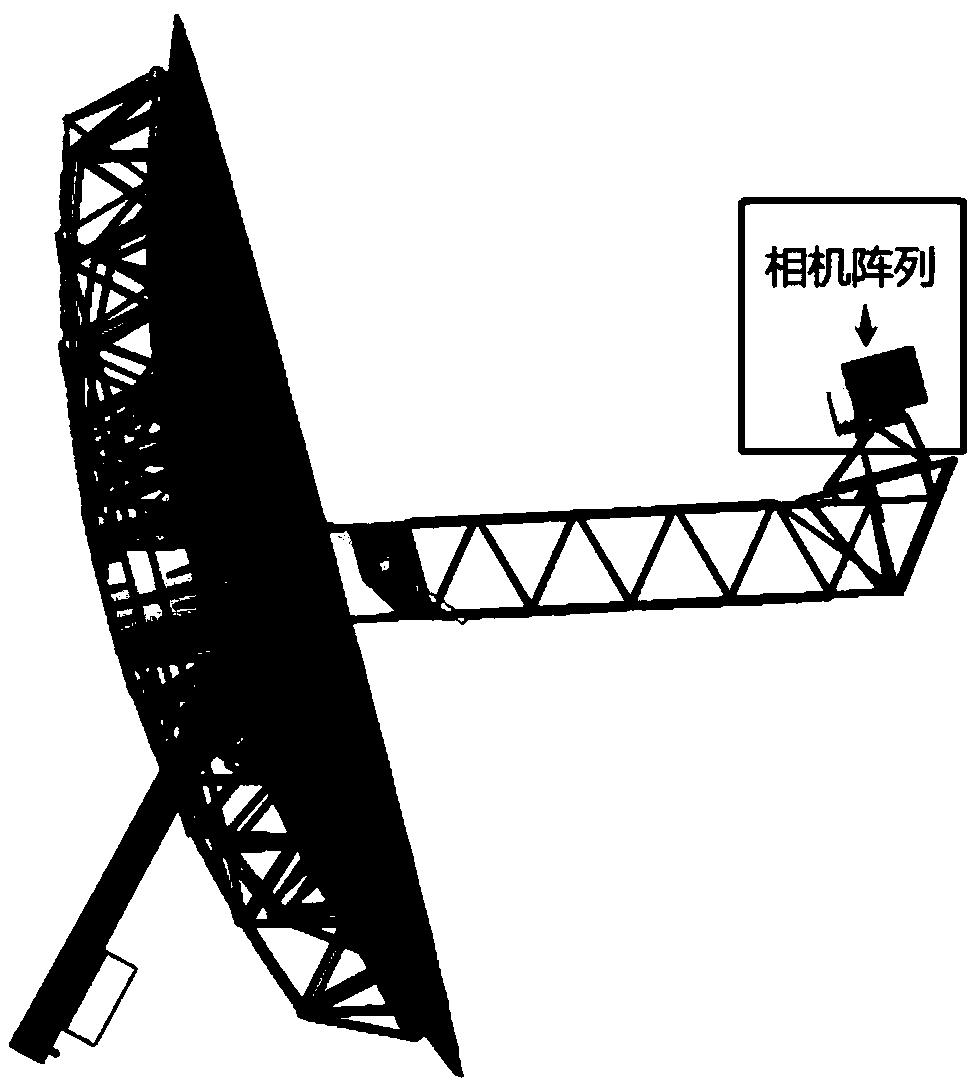

[0052] Step 1, camera array construction. Such as Figure 3-8As shown, in this embodiment, 4 industrial cameras are used to construct a camera array. The camera is connected with the main support by a fixed bracket. The main bracket consists of two longitudinal brackets 2 and two beams 3 to form a 'well'-shaped structure. The bottoms of the two longitudinal brackets 2 are respectively connected to the bottom bracket 1, and the joints of the longitudinal brackets 2 and the beams 3 also use fastening devices 4 Triangular support is carried out; the camera tray and the support structure 5 are divided into two ends located at the two ends of the beam 3, the camera is arranged on the camera tray, and the longitudinal bracket 2 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com