A method for predicting the critical temperature load on the outer edge of a woodworking circular saw blade

A woodworking circular saw and critical temperature technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of circular saw blade resonance instability, etc., to increase critical temperature load, improve service life, and calculation efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0065] Take a woodworking circular saw blade with an outer edge diameter of 355mm, a flange diameter of 120mm, and a thickness of 2.2mm as an example. The base steel of the circular saw blade is 75Cr1, the elastic modulus is 210GPa, Poisson’s ratio is 0.3, and the density is 7.8g / cm3.

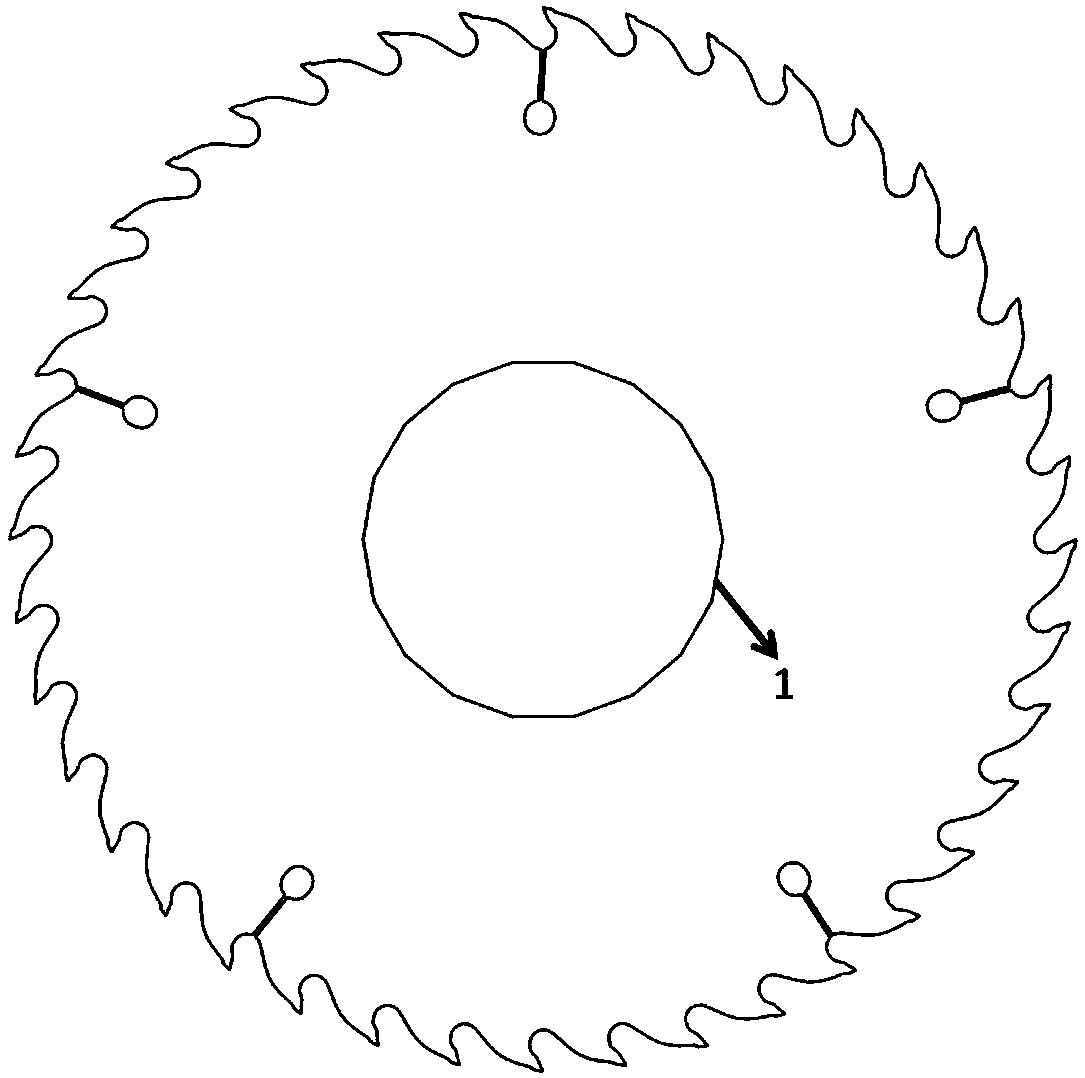

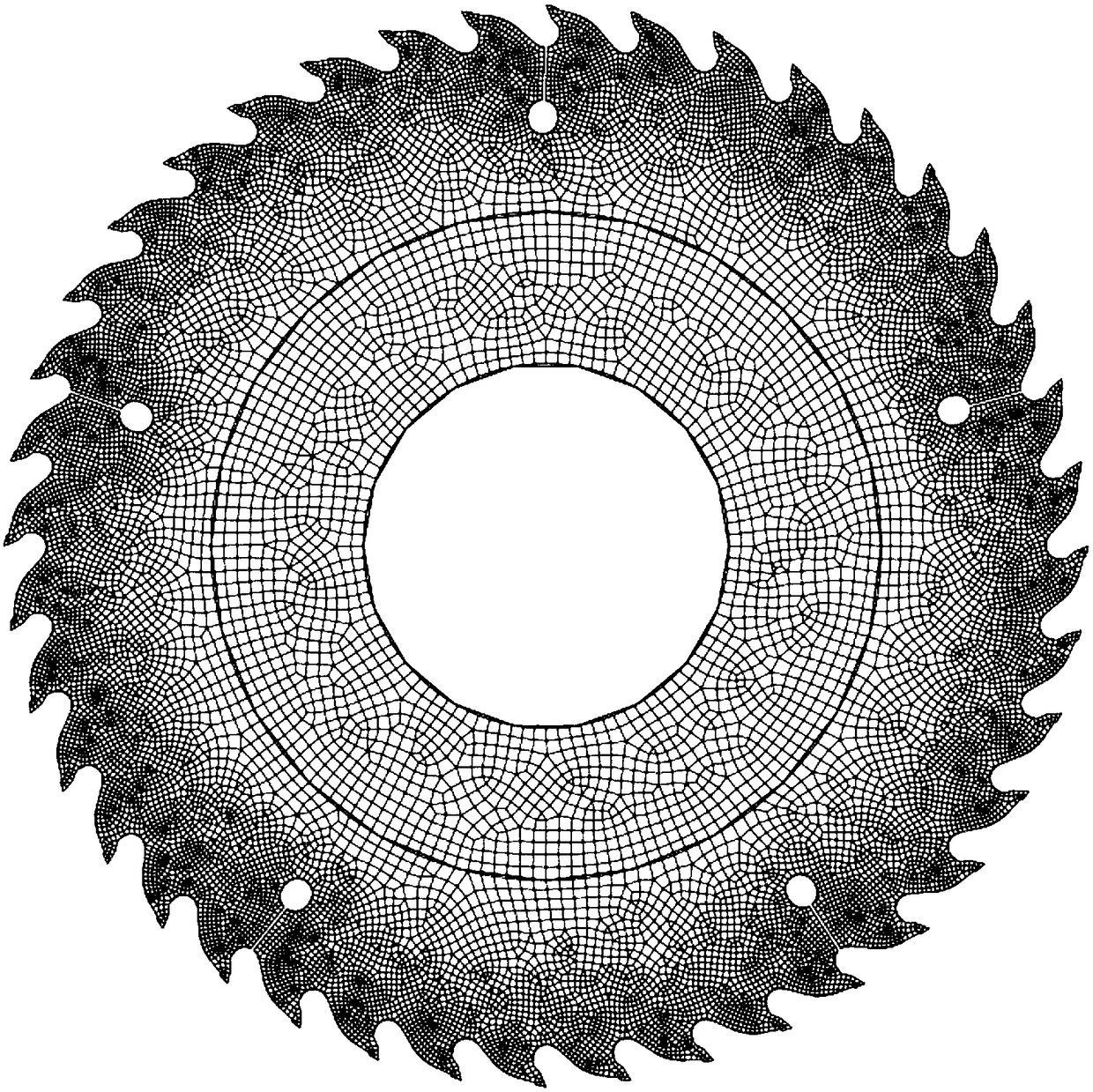

[0066] Import the design drawings of circular saw blades into ABAQUS or other finite element software, or perform geometric modeling on circular saw blades directly through ABAQUS or other finite element software, such as figure 1 shown.

[0067] figure 1 Among them, 1 is the outer edge of the circular saw blade flange, and a fixed constraint is imposed on the outer edge of the circular saw blade flange.

[0068] The working speed of the circular saw blade is 3000 rpm, so its rotational frequency is 50 Hz, and a rotating centrifugal force is applied to the base of the circular saw blade.

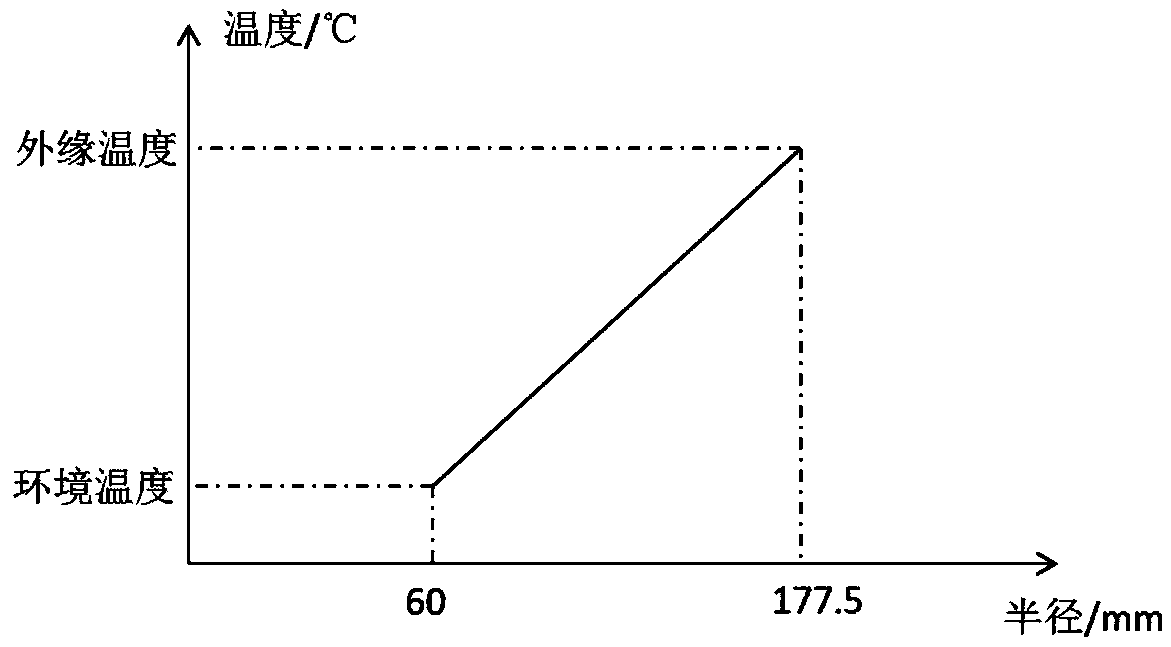

[0069] The temperature in the circumferential direction of the circular saw blade is uniformly distribut...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap