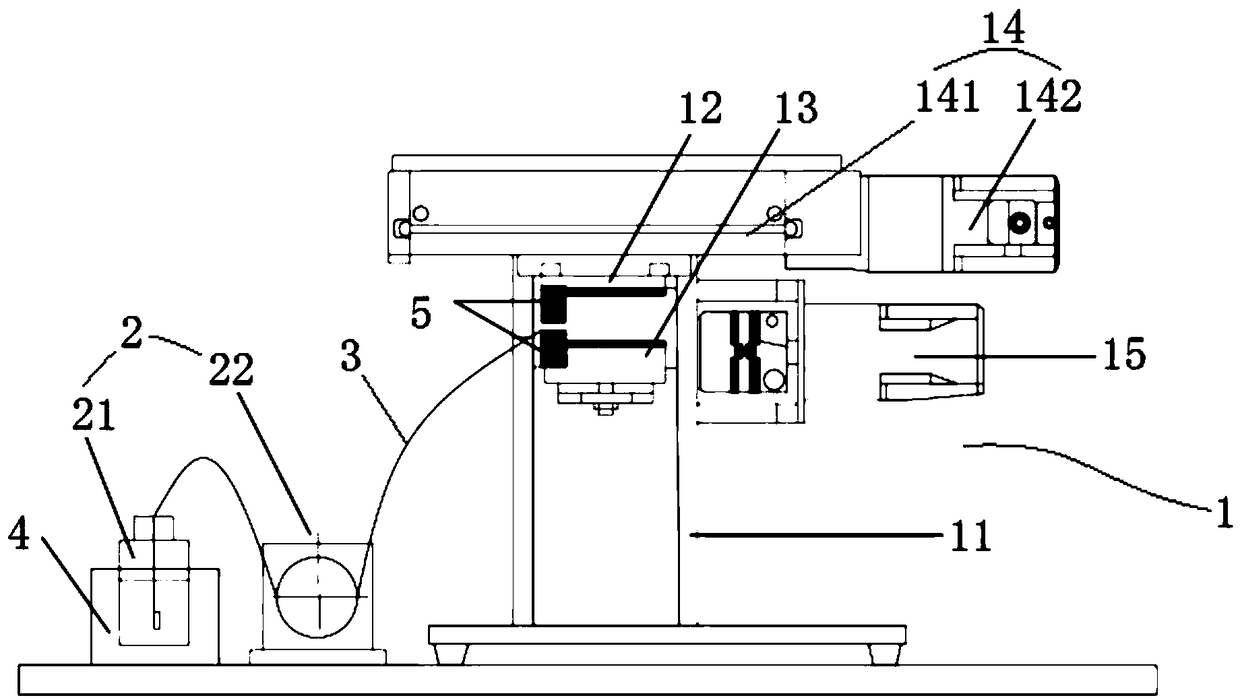

Bionic oral cavity food processing system and method

A technology of food processing and oral cavity, which is applied in the field of bionic oral food processing system, can solve the problems of being unable to reproduce the food processing process and ignoring the mixing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

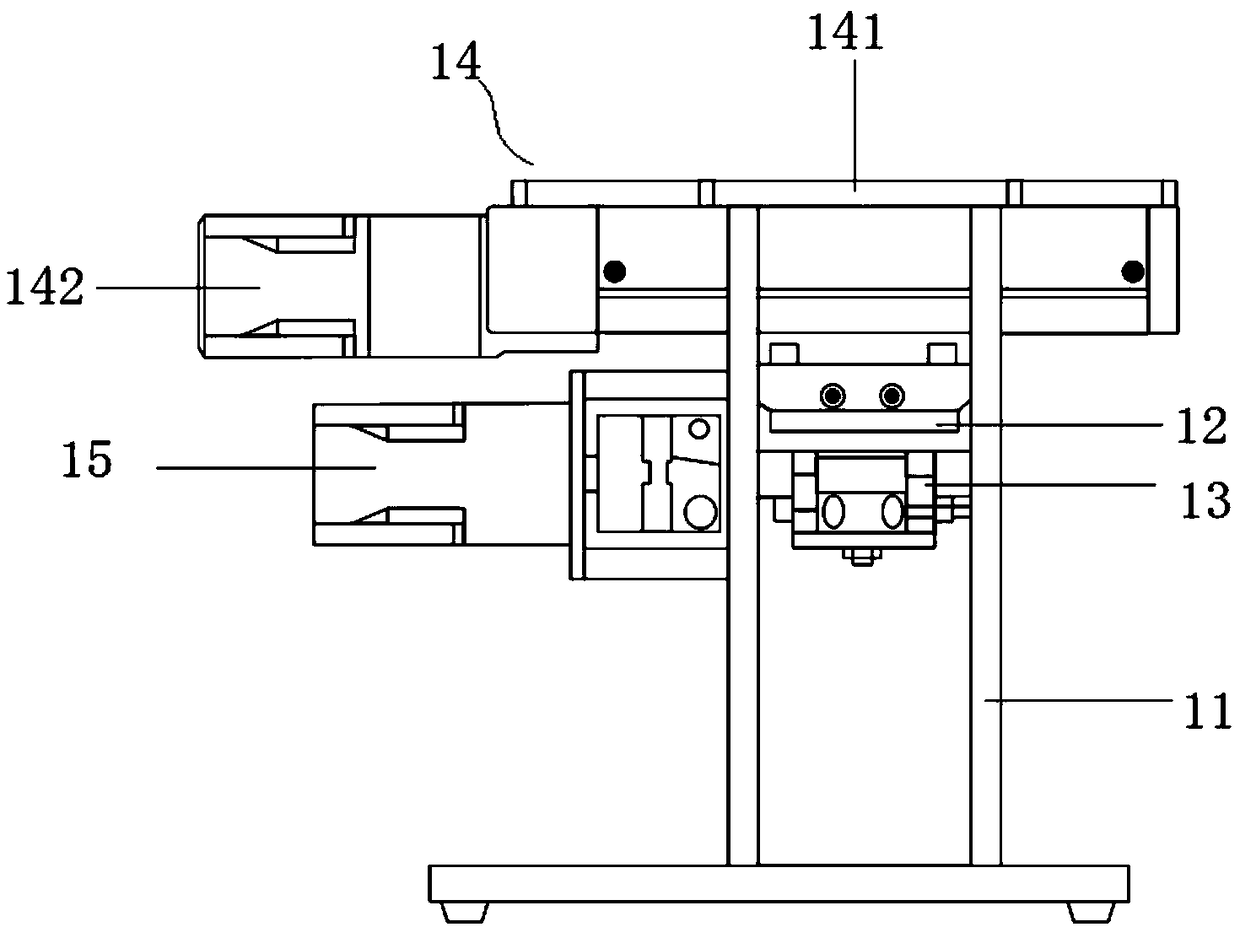

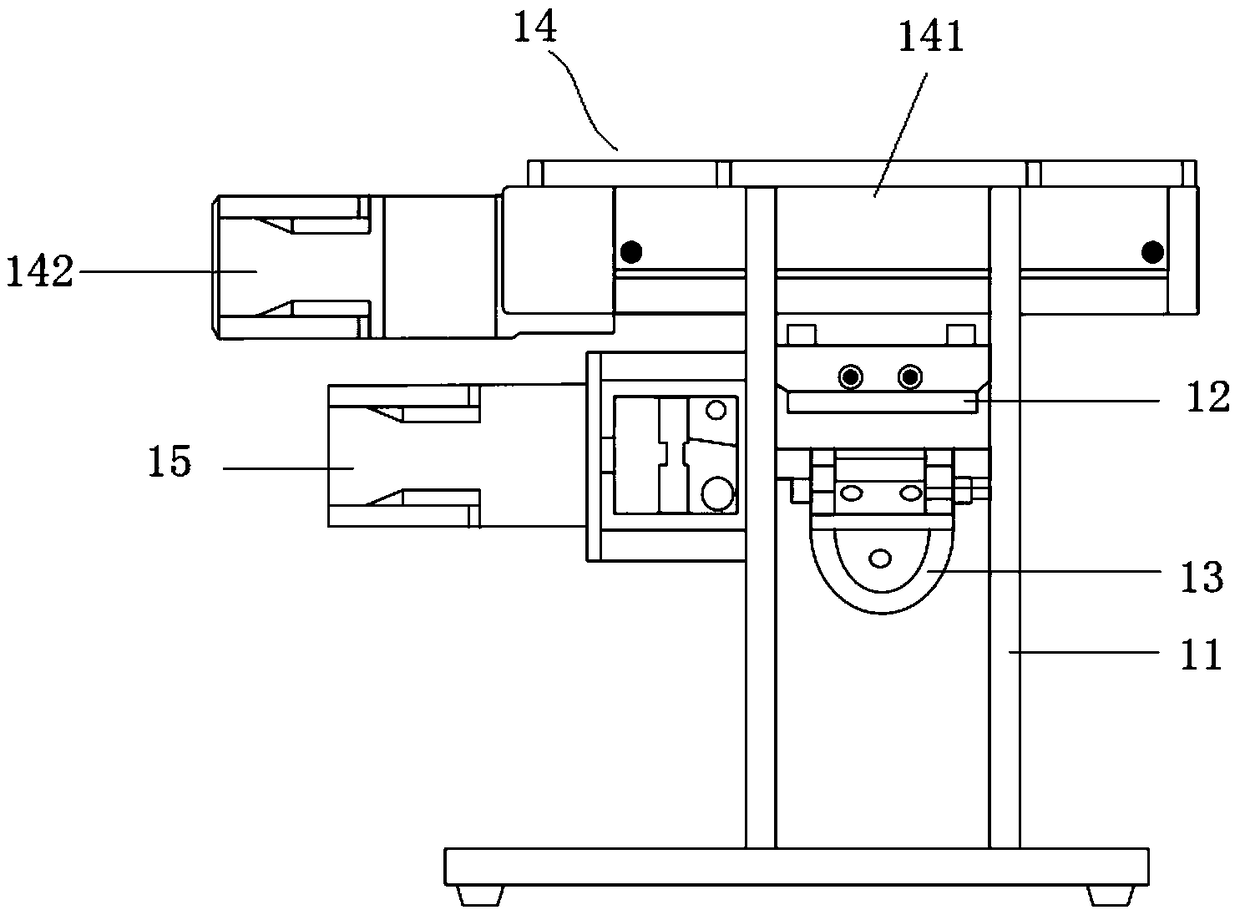

Examples

Embodiment

[0069] like Figure 7 As shown, the motion parameters of the linear driver, the rotary driver and the transmission flow rate of the artificial saliva are respectively set in the controller and the cooperation between them is guaranteed.

[0070] (1) Preparation of artificial saliva: first prepare artificial saliva electrolyte solution, wherein the concentration of inorganic salts is 12.16mmol / L KCl, 2.96mmol / L KH 2 PO 4 ,1.09mmol / L NaHCO 3 ,0.12mmol / L MgCl 2 (H 2 O) 6 ,0.048mmol / L(NH 4 ) 2 CO 3 and 0.15mmol / L CaCl 2 . Dissolve salivary amylase in this electrolyte solution to achieve an enzyme activity of 75 U / ml. Pour the prepared 30mL artificial saliva into the artificial saliva storage container and store it in a water bath control system at 37°C and heat it to a constant temperature state of 37°C.

[0071] (2) Set the execution parameters of the controller of the drive motor in the upper control computer: translate 10mm in the direction of the food baffle, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com